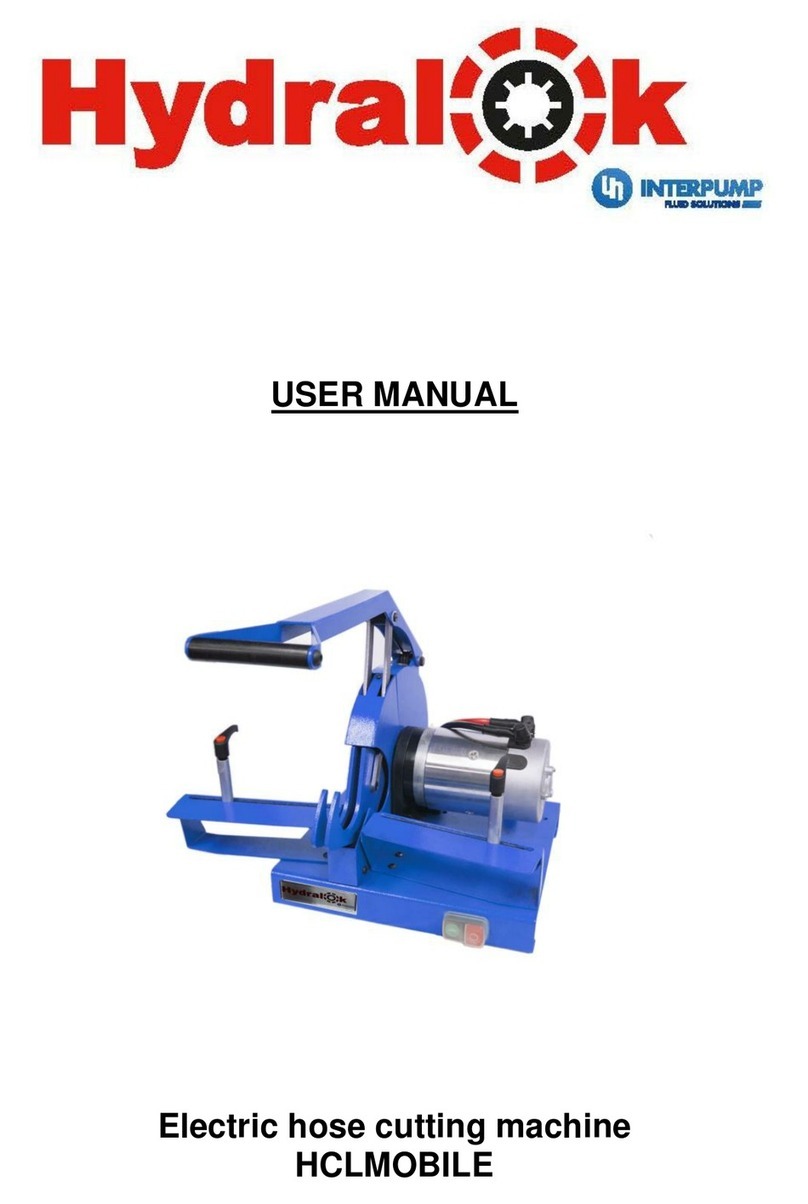

Interpump Hydralok HCL Mobile User manual

HCL Mobile

Hose Cutter

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 2r1

Contents

Warranty Conditions...............................................................................................................................3

Information Relating to Cutting Blades ..................................................................................................4

Guidelines for Correct Cutting ............................................................................................................ 4

Blade Wear..........................................................................................................................................4

Replacement Blades............................................................................................................................4

EC Declaration of Conformity ................................................................................................................. 5

Safety Regulations...................................................................................................................................6

Machine Manual .....................................................................................................................................7

Technical / Dimensional Data .............................................................................................................7

Unpacking from Transport ..................................................................................................................7

Preliminary Checks..............................................................................................................................7

Routine Maintenance .........................................................................................................................7

Machine Description ...........................................................................................................................8

Installation ..........................................................................................................................................8

Operating Instructions ........................................................................................................................8

Maintenance and Service....................................................................................................................9

Noise Emissions...................................................................................................................................9

Appendix 1 –Mounting Information ....................................................................................................10

Appendix 2 –Wiring Schematic ............................................................................................................ 11

Appendix 3 –Machine Diagram............................................................................................................12

Appendix 4 –Blade Replacement Instructions .....................................................................................14

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 3r1

Warranty Conditions

Note! All machines undergo strict testing prior to shipment.

The user manual must be read and understood in full prior to use of the machine.

1. All machines are warranted against any defects for a period of SIX MONTHS starting from

the date of delivery to the customer. The company reserves the right to require a copy of

the sales invoice or proof of purchase.

2. Defects must be verified, therefore each defective item must be returned to our address

with SHIPPING CHARGES PREPAID IN FULL. We will return the item with CARRIAGE

FORWADED. ALL DELIVERIES TO OUR COMPANY WITH CARRIAGE FORWARD WILL BE

RETURNED TO THE SENDER.

3. The machine warranty covers replacement or repair of any component found to be

defective due to manufacturing or assembly.

4. Replacement parts and repairs carried out during this six month period do not extend the

duration of the machine warranty.

5. The warranty does not cover damage caused by deterioration form use, or damage caused

by improper or negligent machine maintenance.

6. The warranty does not cover damage due to improper use, or misuse. The warranty does

not cover damage caused by use outside of compliance with this machine operation

manual.

7. The warranty is not valid in case of any unauthorised machine modification.

8. This machine manual is to be considered as a certificate of warranty, valid only for the

machine to which it pertains, commencing on the date indicated on the freight bill.

9. The cutting blade is covered by a specific set of guidelines, detailed overleaf.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 4r1

Information Relating to Cutting Blades

Guidelines for Correct Cutting

Initially, a new blade should be broken in. This is achieved by using the blade very carefully for 15-20

cutting operations on a hose size which does not demand the full capability of the machine.

It is essential that the hose is forces to bend away from the blade using the provided hose support

pillars. It is also essential that the bend is symmetrical about the cutting edge.

When cutting a hose the hose must not be ‘slammed’ or forced unnecessarily against the blade as

this can cause blade fracturing or cracking, leading to premature blade failure. An elevated cutting

speed will have an inversely proportional effect on the quality of the cut, and of the life of the blade.

Avoid twisting the hose during the cutting operation as this can impact the quality of the cut.

Blade Wear

Each blade is subject to high forces during normal operation and will show signs of wear over time. It

is not possible to guarantee a blade for a number of cuts or a duration of time as this is entirely

subjective and all blades will experience a different duty cycle.

The warranty of the cutting blade is extended only to defects in geometry and manufacturing, and

does not cover excessive wear or failure due to improper or abusive use.

Replacement Blades

The cutting blade is the only consumable element of the HCL mobile cutter, and is the only element

which will be readily available for spares.

It is recommended that only cutting blades obtained from the original machine supplier be used with

the machine.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 6r1

Safety Regulations

Always work in safe conditions and with the necessary personal protective equipment (PPE) and

space around the machine. Ensure that the machine is secured onto a stable flat work surface, and

bolted down using a minimum of two bolts set at opposing corners through the holes provided.

1. DO NOT USE any of the equipment before fully reading and understanding the machine

manual.

2. DANGER! If improperly used the machine can be dangerous and may cause injury. Heed all

warning notices and do not touch operational or moving elements of the machine, especially

during operation.

3. WARNING! It is absolutely essential that all working operations are carried out by a SINGLE

OPERATIVE at any one time.

4. This manual must be presented to the machine operative, and it must be ensured that the

machine operative must fully read and understand the manual, and his/her responsibilities

with regard to machine operation.

5. Machine guards should NEVER be modified, tampered with or removed. Doing so will void

any remaining warranty

6. (Where applicable) A fully trained and competent electrician must connect the machine to

an appropriate power supply.

7. Always wear protective GLOVES, SAFETY GLASSES and APPROPRIATE CLOTHING. Ensure

LONG HAIR is TIED BACK to prevent entanglement.

8. (Where applicable) Isolate the machine from the power supply before removing any covers,

or attempting any maintenance. A trained and competent electrician must be present for all

works on electrical elements and components of the machine.

9. Only ORIGINAL spare parts may be used for the maintenance of the machine.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 7r1

Machine Manual

Technical / Dimensional Data

Category

HCL mobile Cutter

Capacity

1¼” 4-wire, 1½” 2-wire braided hydraulic hose

Machine Dimensions (mm)

467 x 387 x 486 (approx.)

Net Weight (Kg)

23

Voltage

12v / 24v DC

Noise Level

(Not Exceeding) 75dB(A)

Unpacking from Transport

The machine will be shipped bolted on opposing corners to a wooden pallet. The bolts should be

removed and the machine lifted onto the work surface using suitable lifting equipment and

guidelines.

Preliminary Checks

Ensure that the intended work surface is pre-drilled with mounting holes to bolt the machine down.

Dimensions for mounting holes can be found in Appendix 1 –Mounting Information.

Ensure that there is a suitable power source nearby and that the power supply line is fitted with a

differential safety breaker and overload cut-out.

The machine does not have any integrated lighting, so ensure that the machine is positioned in an

area with ample lighting and that the working area is suitably illuminated.

Routine Maintenance

Ensure that moving parts are always lightly greased and free of dust and debris.

(Where applicable) Check that limit and safety switches are operational, and that safety switches

and emergency stop buttons are in good working order.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 8r1

Machine Description

A bench mounted, electrically powered rotating circular, toothed knife. Cutting operation is

powered by hand. The machine is intended to be used for cutting steel wire reinforced rubber

hydraulic hose or similar.

Installation

The machine must be fixed to a firm, and level work surface, bolted down by a minimum of two

bolts located in opposing corners of the machine. Mounting information can be found in Appendix 1

–Mounting Information.

Connections should be made to an appropriate 12v / 24v DC electrical supply by a qualified

electrician. Standard wire colour coding is applied where the RED wire terminal must be connected

to the positive/live supply terminal, and the BLACK wire must be connected to the negative/neutral

supply terminal. For electrical schematic see Appendix 2 –Wiring Schematic.

A separate 160 - 180 amp battery coupled to a split charger is recommended. Alternatively a 110 -

120 amp battery can be used for light duty. To ensure a maximum 12 volt DC supply is delivered to

the machine, a minimum cable size of 25 mm square with a maximum length of four meters can be

fitted. A suitable isolator and overload protection device should be fitted to the voltage supply line.

Prior to operation, ensure that the blade is free to rotate without fouling on any of the guards and

that the guards are operating correctly and covering the cutting blade completely.

Operating Instructions

To move the hose support pillars (object 4 of Appendix 3 –Machine Diagram), unscrew the clamping

handle 1-2 rotations, slide the pillar to position, and re-tighten the clamping handle. Set the hose

support pillars an equal distance apart from the blade, so that when the handle (1) is pushed down

the hose is put under reasonable bending strain to relieve pressure on the sides of the blade during

the cutting operation.

Place the hose into the cutting jaws (6) so that the hose bends out towards the user and is

supported by the hose support pillars (4). Ensure that the cutting mark is directly between the hose

cutting jaws (6). Switch on the machine using the green portion of the control button (3) and push

the handle downwards SLOWLY. Allow the blade to cut through the hose at a controlled rate

without excessive slowing of the blade. When the hose is cut, allow the handle to return to a fully up

position where the blade is fully covered and switch off the machine using the red portion of the

control button (3).

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 9r1

Maintenance and Service

Regular inspection and routine cleaning of the machine, focussing especially on the guards

(Appendix 3 - 7 & 8). Under no circumstances should the machine be used if the guards have been

damaged or removed.

The cutting blade should be inspected regularly for signs of wear or damage. DANGER! The machine

must not be run if the blade shows signs of damage or stress cracking as projectiles may cause

serious injury as the blade rotates at very high speeds.

To replace the blade, follow the instructions in Appendix 4 –Blade Replacement Instructions.

Noise Emissions

Readings taken of this model of machine, mounted on a wooden work bench in the working position

at a distance of 1.1m above floor level was 75dB(A).

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 14 r1

Appendix 4 –Blade Replacement Instructions

The following instructions detail how to change the cutting blade of the HCL mobile Cutter.

DANGER! Cutting blades are extremely sharp and must be handled with extreme care at all times to

avoid injury.

Remove four M6 dome head bolts from the front guard (two each side) and the M4 bolt at the top

of the front guard, as shown above. And remove the front guard by sliding it forwards as shown

below.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 15 r1

Remove the two M6 socket cap bolts from the pivot block as shown above. Note! that the tension

within the handle spring will attempt to work against this operation during undoing. Pivot the

handle, and pivot linkages, the cutting jaws, and the pivot block up above the rear cover as shown

below.

Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

P a g e | 16 r1

Remove the M6 clamp plate bolts (x2) by locating a bar or hex key into the torsion restraint holes in

the blade boss, shown above. Once both bolts have been removed the clamp plate can be removed

and the blade can be carefully removed and replaced as shown below ensuring that the teeth are

pointing in the correct direction. Once the new blade is installed these steps can be repeated in

reverse to reinstate all of the machine components. Ensure that thread locker is applied to the blade

clamp bolts on reassembly to prevent loosening over time.

Table of contents

Other Interpump Cutter manuals

Popular Cutter manuals by other brands

Sparta

Sparta Huskie TOOLS REC-630Y Operation manual

MEISTER CRAFT

MEISTER CRAFT MEF 600 manual

Hellermann Tyton

Hellermann Tyton CUTties-1 operating instructions

FLORABEST

FLORABEST PRC 9.6 Operation and safety notes

Far Tools

Far Tools TCS 200 Original manual translation

LaserMech

LaserMech FiberCUT 2D Operation manual

Sparta

Sparta Huskie Tools REC-B660YC Operation manual

Central Pneumatic

Central Pneumatic ROTARY CUTTING TOOL 97007 Set up and operating instructions

Dolmar

Dolmar PC-6114 Operator's and safety manual

SummaSign Pro

SummaSign Pro SL T-series user manual

Husqvarna

Husqvarna K 7000 Operator's manual

Cedima

Cedima CF-12.4 E-TR Operating manual and safety instructions