Intersan GalvinCare WM-TMVPMSCS Instruction manual

Version 1, 6 June 2018, Page 1of 5

GalvinCare ® Thermostatic Progressive Mixer

PRODUCT CODES:

- WM-TMVPMSCS

SPECIFICATIONS

This progressive shower mixer provides state of the art features to comply with healthcare requirements.

The GalvinCare®paddle handle provides straight forward temperature control and minimises ligature risk.

Suitable for high and low pressure systems with a thermostatically controlled water temperature of

113°F/45°C maximum.

Enables water to be mixed closer to the point of discharge, minimising stagnant warm water which provides

ideal conditions for legionella bacteria to grow.

Smooth internal components and body reduces scale build-up and bacteria growth.

Maximum temperature limiter fitted for protection from accidental scalding.

Water flow starts from cold ensuring safe usage.

Clean smooth lines facilitate fast and easy cleaning.

All servicing and commissioning can be done without removing the device. Easy access isolators, help

minimise time spent on commissioning and maintenance.

Designed to provide stable mixed temperature with rapid shut down in the event of cold or hot water supply

failure.

IMPORTANT: All GalvinCare®mental health fixtures leave our premises in good working order. The

following instructions must be followed in all respects and read in conjunction with Clinimix® Progressive

Thermostatic Mixing Valve Manual.

TECHNICAL DATA

Inlet

½” NPT –Male

Outlet

½” NPT –Male

Headwork

Thermostatic mixing valve

Working Pressure Range (psi/kPa)

Min

3/50

Max

72.5/500

Working Temperature Range (°F/°C)

Min

41/5

Max

185/90

Finish

Chrome

NOTE: Galvin Specialised continually strive to improve their products. Specifications may change without notice.

PRE-INSTALLATION

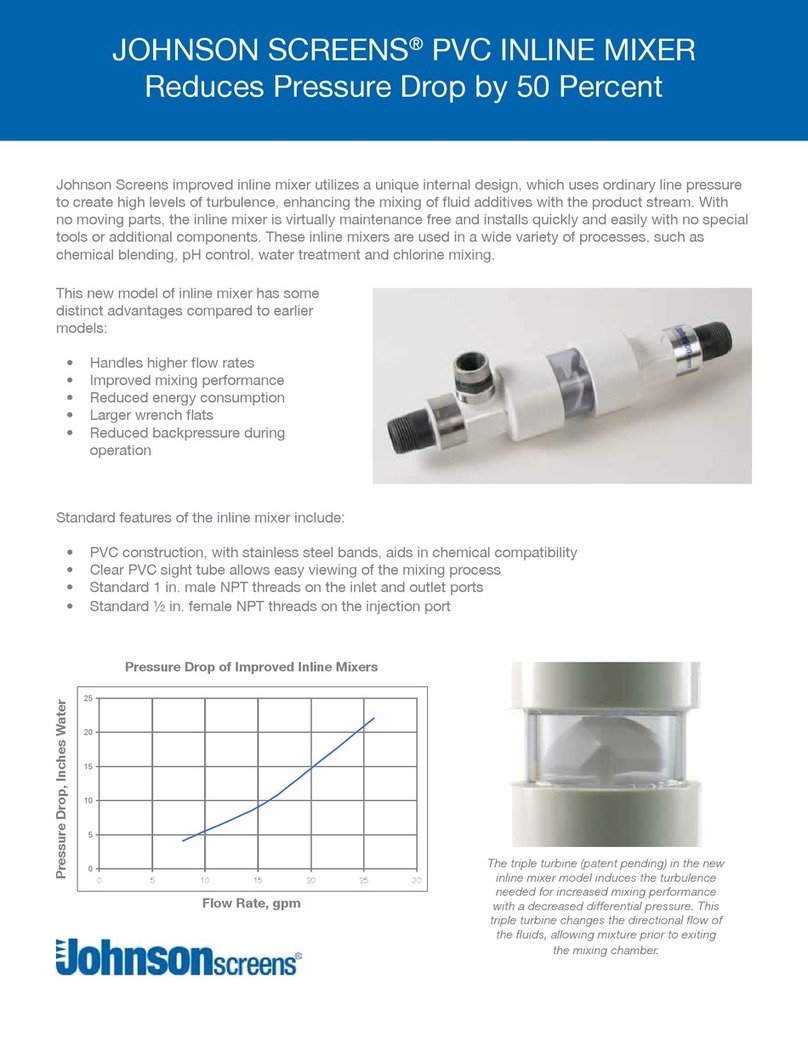

MOUNTING DETAILS –OVERALL DIMENSIONS

The rough in details have

been provided to show correct

fitment of the Progressive

Shower unit (see side image).

The unit must be mounted so

that the inlet is horizontal and

the outer plastic box of the

Progressive shower unit

stocks out of the finished wall

(to a maximum 3/8”or 10mm)

Version 1, 6 June 2018, Page 2of 5

TOOLS REQUIRED

Power drill

Spanner and hex key

INSTALLATION

INSTALLATION COMPLIANCE: Galvin Specialised products must be installed in accordance with these

installation instructions and in accordance with local regulatory requirements. Water and/or electrical supply

conditions must also comply to the applicable national and/or local standards. Failing to comply with these

provisions shall void the product warranty and may affect the performance of the product.

IMPORTANT: Whilst our product designs take into account a broad range of installation types and surfaces, it

is important that surfaces which fixtures are mounted to are flat and free from defect. This is especially

important when installing product ranges that have been designed for correctional and health facilities, where

special attention is required to minimise ligature points and areas for concealment of contraband. In addition to

ensuring the products are fitted securely and in accordance with the following instructions, consideration shall

be given to the use of non-pick mastics such as Sikaflex 11FC or Dow Corning 995 Silicone Structural Sealant

to ensure a high quality and safe installation.

1. Fit body assembly

Fit hot and cold water supplies to the correct

side of the shower unit and the outlet to the

shower head. To make this easier the outlet

can be changed from one end to the other by

swapping it with the opposite plug. Do not use

heat on any of these connections as it will

damage the shower.

Note: Hot and cold inlet cannot be swapped.

2. Fit face plate

Fit the faceplate and shower flange.

Ensure faceplate anti-rotation pin sits correctly

and the o-ring is fitted underneath the flange..

3. Secure flange

Secure the flange with the three supplied

screws.

Use supplied M6x20mm long screws, if not

suitable change to M6x16mm long screws.

4. Fit handle

Secure the handle with supplied tamper proof

screw.

Ensure the handle is oriented correctly.

Version 1, 6 June 2018, Page 3of 5

SERVICE AND MAINTENANCE (see supplied booklet for complete details)

1. Disconnect water line

Turn off the water supply and turn on the

tap handle to release any pressure in the

lines

Disconnect cold, hot & outlet water

connections

2. Remove handle assembly

Unscrew the tamper proof screw from handle

Pull out handle assembly from the body

3. Remove faceplate and flange

Unscrew the three screws and pull out the

flange and faceplate from unit.

4. Isolate the shower

To isolate the shower, remove clips, and loosen the

isolators in an anti-clockwise direction until it’s flush

with the face of the body. This closes the shut off

valves.

Fully remove isolator to access non return valve and

clean strainers.

To re-open the shutt off valves tighten the valve

regulator/check valve/filter units until tightened (do

not over tighten) and refit the two clips.

5. Remove cartridge nut and check cartridge

Unscrew cartridge and remove from

body. Check the cartridge for wear and

damage. Replace if required.

Check and clean the body of all debris.

6. Re-assemble

Re-assemble, by reversing steps 5 to 1.

Turn on water and check for correct operation.

Once fitted turn on water and check for leaks and

correct operation.

Version 1, 6 June 2018, Page 4of 5

TROUBLESHOOTING

PROBLEM

CAUSE

RECTIFICATION

The desired mixed water

temperature cannot be

obtained or valve is difficult

to set.

Hot and cold supplies are installed to

the wrong connections

Thermostatic cartridge contains

debris or is damaged

Strainers contain debris

Non-return devices are damaged

Refit the valve with hot/cold supplies

fitted to the correct connections

Clean cartridge ensuring all debris is

removed and components are not

damaged. Replace if necessary.

Clean strainers of debris.

Check non-return device is not

jammed

Check for airlocks in the water

supply.

The water temperature

selected is cold yet hot

water comes out.

Hot and cold connections are

installed in reverse.

Re-fit the valve with hot and cold

water supply to the correct

connections.

The thermostatic mixing

valve will not shut down

The hot to mix temperature

differential is not 18°F/10°C or

greater.

Thermostatic cartridge contains

debris or is damaged.

Non-return devices are damaged.

Raise the hot water temperature.

Clean the cartridge ensuring that all

debris is removed.

Mix temperature unstable

Flow rate below 0.5 gpm (2lpm)

Thermostaticcartridge contains

debris or is damaged.

Strainers contains debris.

Non return devices are damaged

Rectify any pressure deterioration

Cleanthe cartridge ensuring that all

debris is removed and components

are not damaged. Replace if needed.

Clean strainers ensuring debris is

removed.

Check non-return device is not

jammed.

Mix temperature changing

over time

Inlet conditions (pressure or

temperatures) are fluctuating.

Strainers contain debris

Install suitable pressure control

valves to stabilise inlet conditions.

Clean strainers ensuring debris is

removed.

Either full hot or cold

flowing from outlet fixture

Upper temperature ring is not

correctly set.

No flow from hot and cold supplies.

Damaged check valves

Re-set temperature to between 95-

115°F (35-46°C) as required

Check water is switched on.

Replace faultu check valves

Water is not flowing from

outlet.

Hot or cold water failure.

Thermostatic cartridge contains

debris or damage.

Strainers contain debris

Restore intlet supplies and check mix

temperature.

Clean the cartridge ensuring that all

debris is removed and components

are not damaged. Replace if needed.

Clean strainers.

Version 1, 6 June 2018, Page 5of 5

All information including dimensions, changes in design and material are subject to

manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

WARRANTY

The warranty set forth herein is given expressly and is the only warranty given by the Galvin Engineering Pty Ltd.

With respect to the product, Galvin Engineering Pty Ltd makes no other warranties, express or implied. Galvin

Engineering Pty. Ltd. hereby specifically disclaims all other warranties, express or implied, including but not limited

to the implied warranties of merchantability and fitness for a particular purpose.

Galvin Engineering Pty Ltd products are covered under our manufacturer’s warranty available for download from

www.galvinengineering.com.au Galvin Engineering Pty Ltd expressly warrants that the product is free from

operational defects in workmanship and materials for the warranty period as shown on the schedule in the

manufacturer’s warranty. During the warranty period, Galvin Engineering will replace or repair any defective

products manufactured by Galvin Engineering without charge, so long as the terms of the Manufacturer’s warranty

are complied with.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for

breach of warranty, and Galvin Engineering Pty Ltd shall not be responsible for any incidental, special or

consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property

which is damaged if this product does not work properly, other costs resulting from labour charges, delays,

vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical,

electrical or any other circumstances over which Galvin Engineering has no control. This warranty shall be

invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the

product.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

WM-TMVPMSCS-inst-Rev1

Table of contents