These instructions are intended to be used as guidelines solely for the installation of the Johnson Screens PVC inline mixer. They

are not to be used with any other product or any other manufacturer’s product. The mixer should only be installed by someone

with knowledge or experience of the state and local plumbing codes and installation of similar devices. The installer should follow

all state and local codes when using this device. The mixer should be inspected every 6 months. Call Johnson Screens at

(800) 935-5727 with any questions concerning the use or installation.

Prior to installation, check to verify that all limitations and guidelines of the mixer are met:

1. The limits of schedule 80 PVC pipe, or any attachments to the mixer, must not be exceeded.

2. The mixer needs to be installed on a cold water supply line.

3. The mixer should only be used in conjunction with approved chemicals.

4. Appropriate water hammer and/or surge suppressors should be installed and working before the mixer is installed.

5. The mixer should be installed at or near a oor drain so that any drips or spills will be captured by the drain.

6. The mixer should be located away from high trafc, child play or other areas where damage can occur.

7. Pipe joint compounds and Teon® paste products may react with PVC, resulting in stress cracks. For best results, use

Teon®tape or Loctite® 55 pipe sealing cord, or equivalent.*

8. Do not use pipe wrenches on the clear pipe section.

Installation process and procedure:

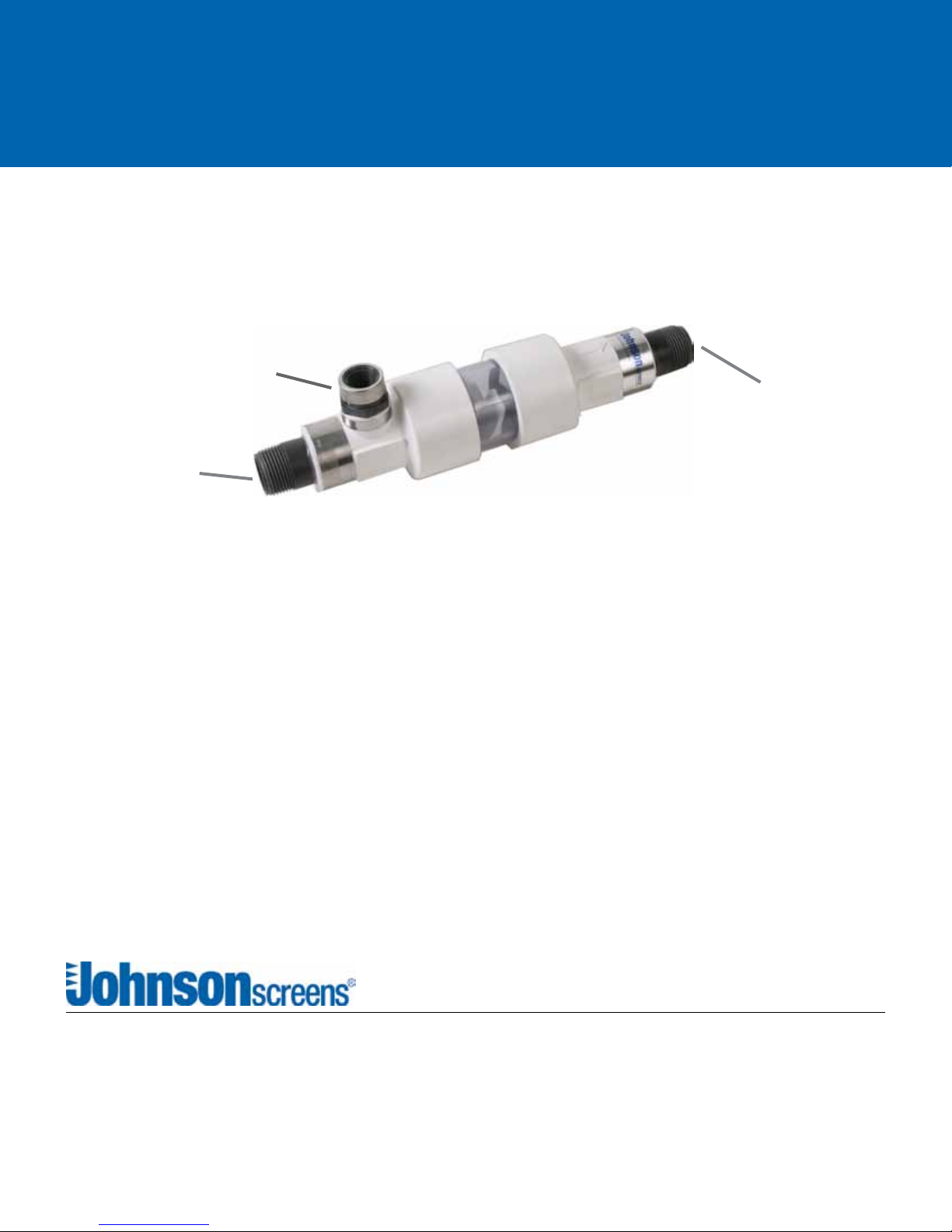

1. In an acceptable installation location, connect the inlet port of the mixer (B) to the water supply source using the 1 in.

male pipe threads on the mixer. Caution: DO NOT OVERTIGHTEN. PVC PIPE THREADS SHOULD BE TIGHTENED

FINGER TIGHT AND THEN 1 TO 2 MAXIMUM ADDITIONAL TURNS. Do not place wrenches on pipe and opposite end

connection. Wrenches must be placed on grey end connection to which pipe is being attached.

2. Attach an outlet pipe to the outlet port (C) of the mixer using the 1 in. male pipe threads on the mixer. Follow over tightening

and wrench placement cautions above.

3. Attach adequate mounting supports to the mixer and connecting piping.

4. Install an appropriate check valve to the ½ in. chemical injection port (A).

5. Install the chemical injection pump to the check valve.

6. Pressurize and test the mixer and chemical injector.

7. Check and correct any leaks.

Disclaimer: The information on this instruction sheet is for informational purposes only. Johnson Screens assumes no liability for any inaccurate, delayed or incomplete

information or for any actions taken in reliance. Copyright ©2009. All rights reserved. No part of these instructions may be reproduced, in any form or by any means,

without permission in writing from an ofcer of Johnson Screens. Johnson Screens Terms and Conditions apply. Contact Johnson Screens for a copy of the T&C if

required. * Teon®is a registered trademark of E.I. du Pont de Nemours and Company; Loctite®is a registered trademark of Henkel Corporation.

JOHNSON SCREENS®PVC INLINE MIXER

Planning and Installation Instructions

A Weatherford Company

Copyright ©2010 All rights reserved to Johnson Screens Inc. 7099.02

AUSTRALIA - ASIA PACIFIC

Johnson Screens Australia

TEL:

+61 7 3867 5555

FAX: +61 7 3265 2768

NORTH, SOUTH & CENTRAL AMERICA

Johnson Screens USA

TEL.:

+1 651 636 3900

FAX: +1 651 638 3171

EUROPE - MIDDLE EAST - AFRICA

Johnson Screens France

TEL.:

+33 (0)5 4902 1600

FAX : +33 (0)5 4902 1616

EMAIL: saleseurope@johnsonscreens.com

www.johnsonscreens.com

B) 1 in. male NPT

thread water inlet

C) 1 in. male NPT

thread mixture outlet

A) ½ in. female NPT thread

chemical injection port