INTORQ | BA 14.0196 | 04/2016 5

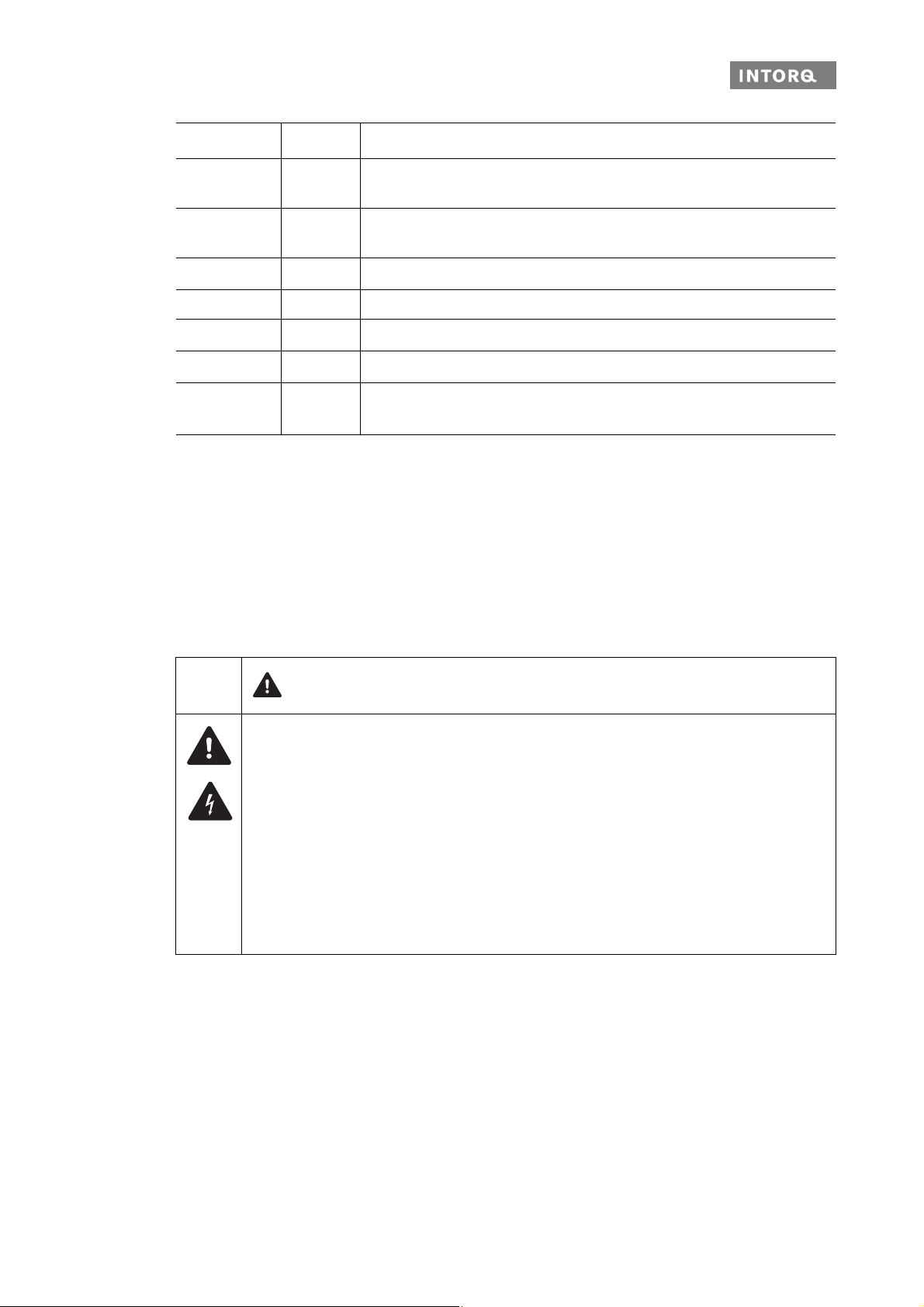

Contents

1 Preface and general information .......................................................................................................................... 6

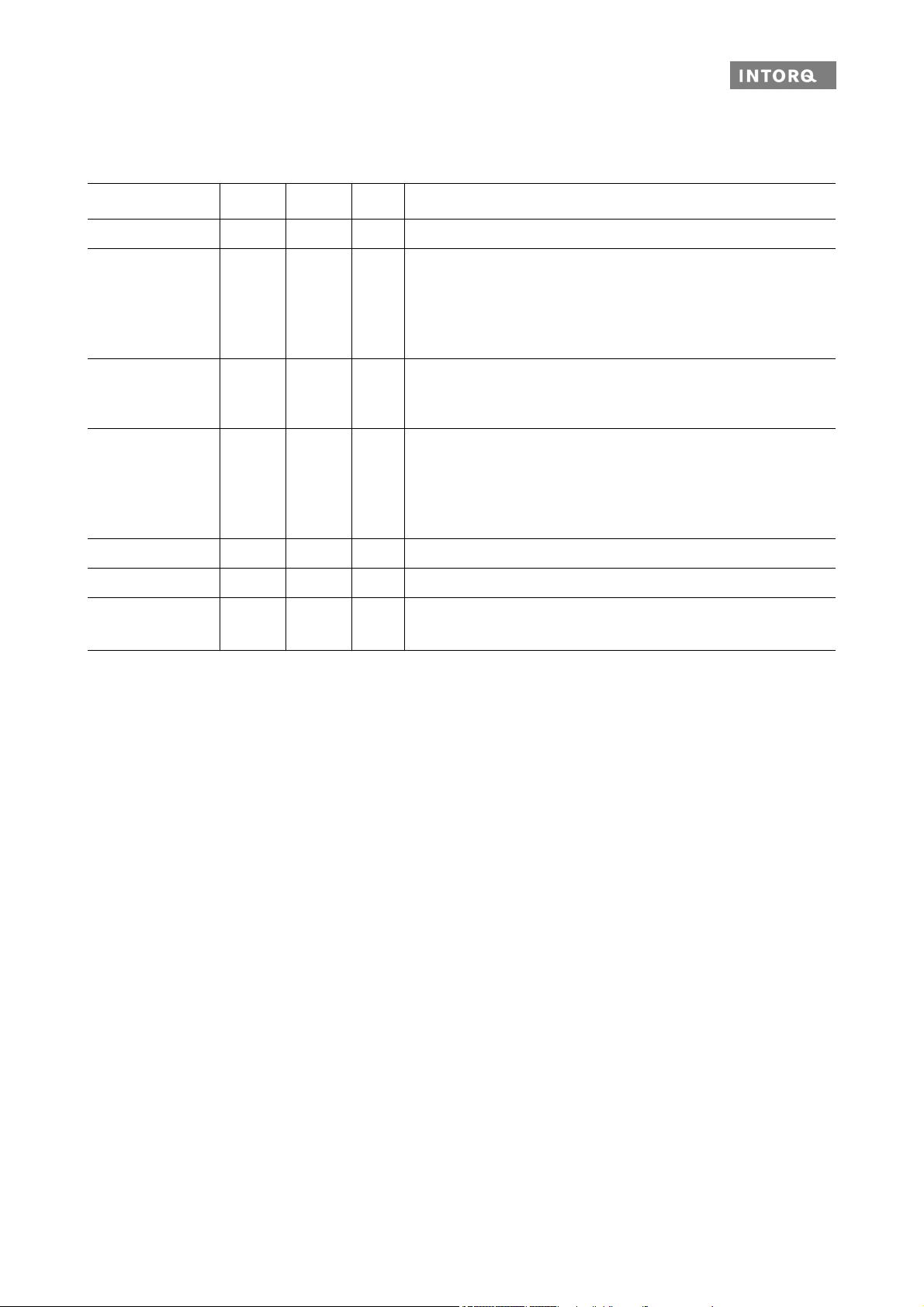

1.1 About these Operating Instructions .............................................................................................................. 6

1.2 Terminology used ......................................................................................................................................... 6

1.3 Conventions in use ....................................................................................................................................... 6

1.4 Abbreviations used ....................................................................................................................................... 7

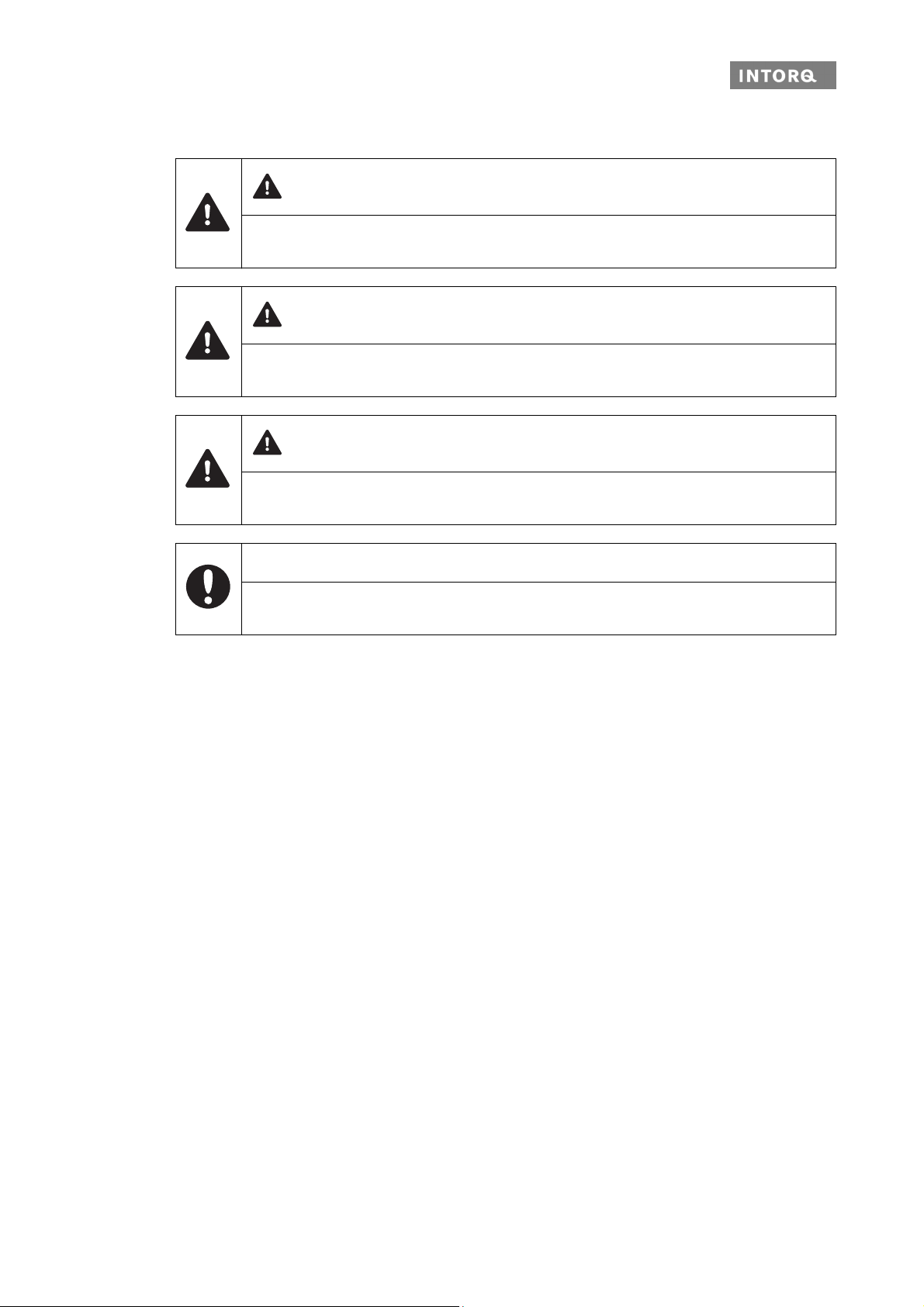

1.5 Safety instructions and notices ..................................................................................................................... 8

1.6 Scope of delivery .......................................................................................................................................... 9

1.7 Disposal ........................................................................................................................................................ 9

1.8 Drive systems ............................................................................................................................................. 10

1.9 Legal regulations ........................................................................................................................................ 10

2 Safety instructions .............................................................................................................................................. 11

2.1 General safety instructions ......................................................................................................................... 11

2.2 Application as directed ............................................................................................................................... 12

3 Technical specifications ..................................................................................................................................... 13

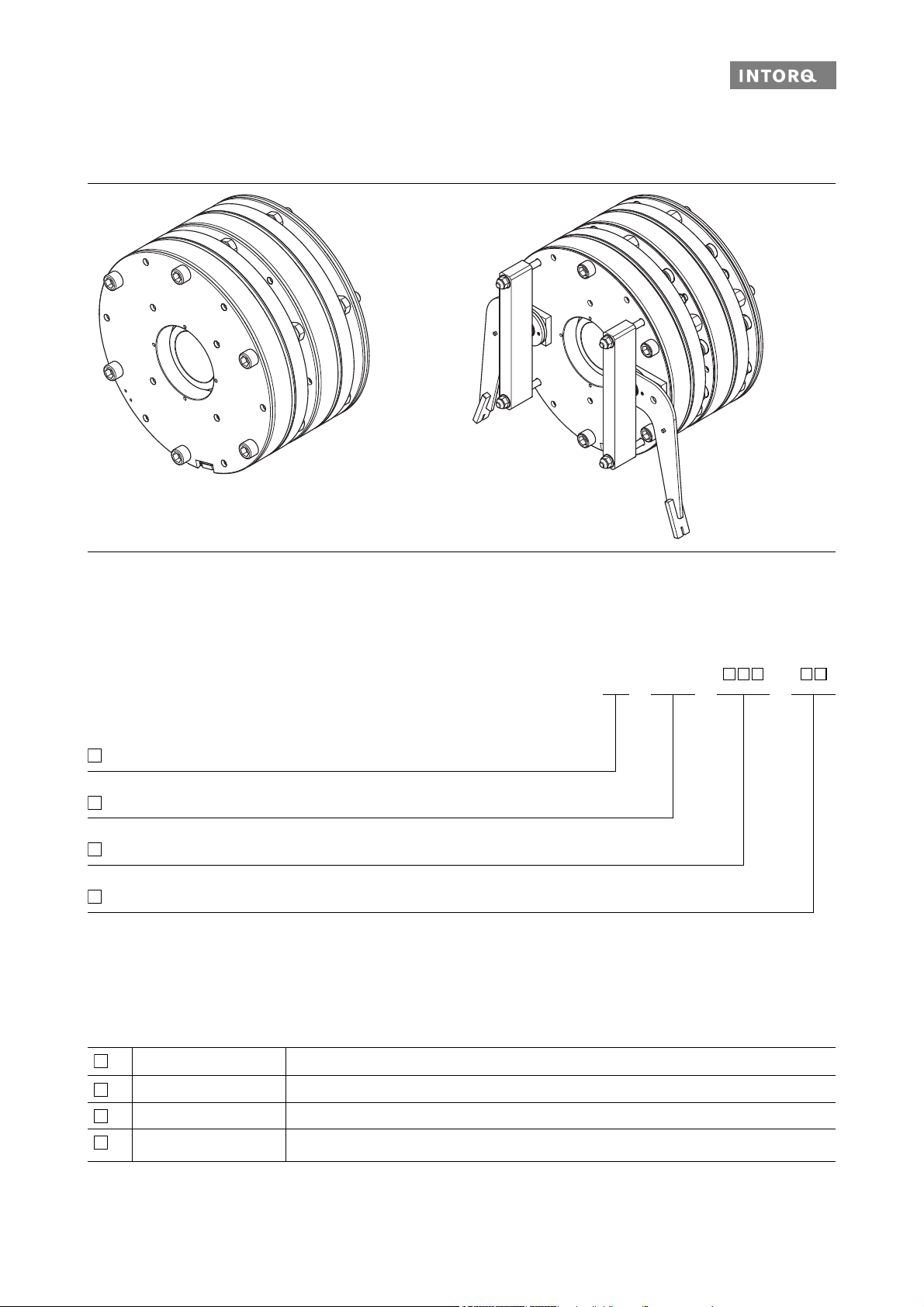

3.1 Product description ..................................................................................................................................... 13

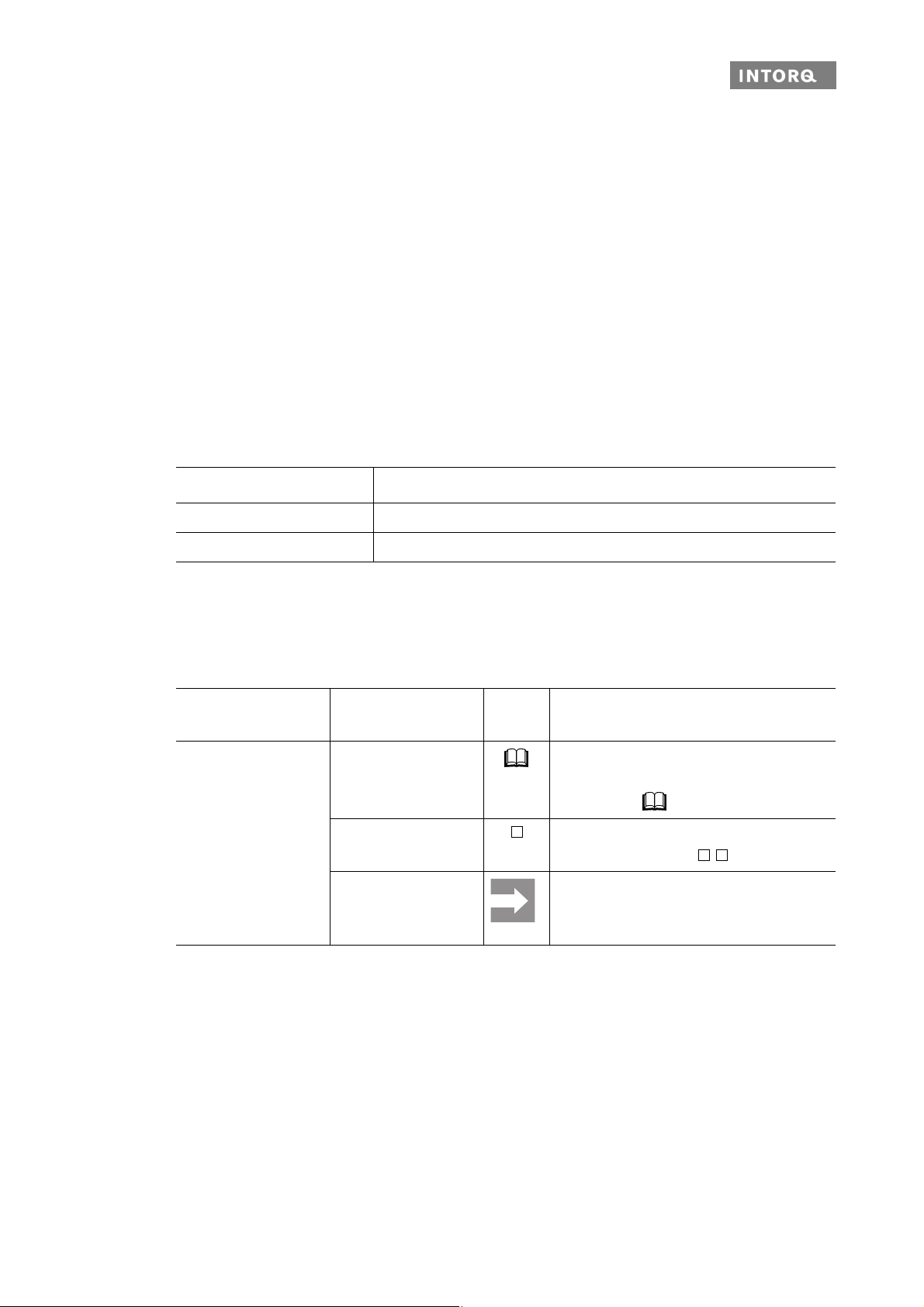

3.2 Rated data .................................................................................................................................................. 16

3.3 Rated data (design data) ............................................................................................................................ 17

3.4 Switching energy / switching frequency ..................................................................................................... 19

3.5 Emissions ................................................................................................................................................... 20

4 Mechanical installation ....................................................................................................................................... 21

4.1 Important notes .......................................................................................................................................... 21

4.2 Necessary tools .......................................................................................................................................... 21

4.3 Assembly .................................................................................................................................................... 22

4.4 Installation .................................................................................................................................................. 23

4.5 Manual release ........................................................................................................................................... 29

4.6 Cover ring assembly ................................................................................................................................... 34

5 Electrical installation ........................................................................................................................................... 35

5.1 Important notes .......................................................................................................................................... 35

5.2 Bridge/half-wave rectifier (optional) ............................................................................................................ 36

5.3 Electrical connection .................................................................................................................................. 38

6 Commissioning and operation ........................................................................................................................... 39

6.1 Important notes .......................................................................................................................................... 39

6.2 Function checks before commissioning ..................................................................................................... 39

6.3 Commissioning ........................................................................................................................................... 40

6.4 During operation ......................................................................................................................................... 41

7 Maintenance and repair ...................................................................................................................................... 42

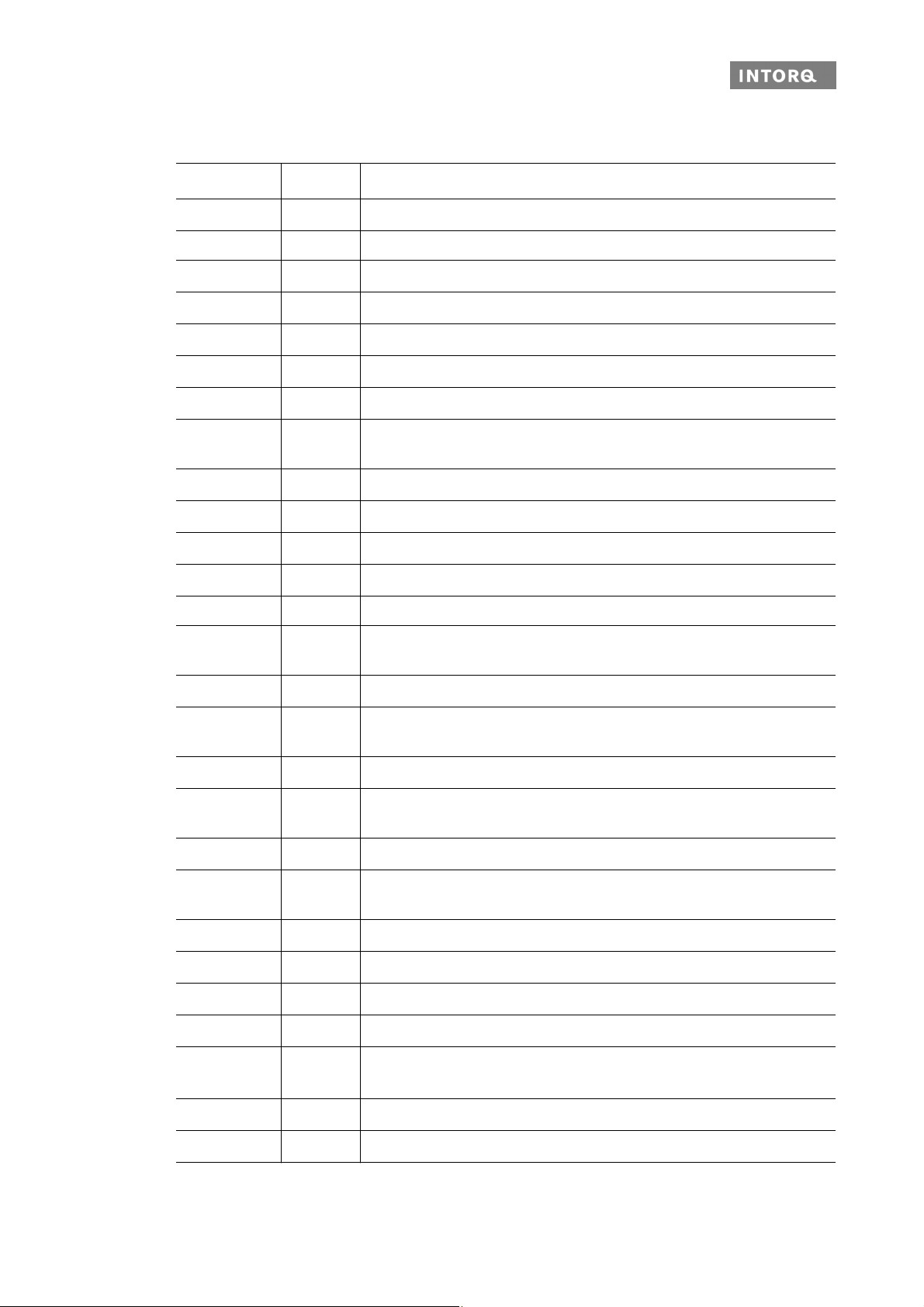

7.1 Wear of spring-applied brakes ................................................................................................................... 42

7.2 Inspections ................................................................................................................................................. 43

7.3 Maintenance ............................................................................................................................................... 44

7.4 Spare-parts list ........................................................................................................................................... 46

7.5 Ordering spare parts .................................................................................................................................. 47

8 Troubleshooting and fault elimination .............................................................................................................. 48