INTORQ | BA 14.0176 | 06/2017 4

Contents

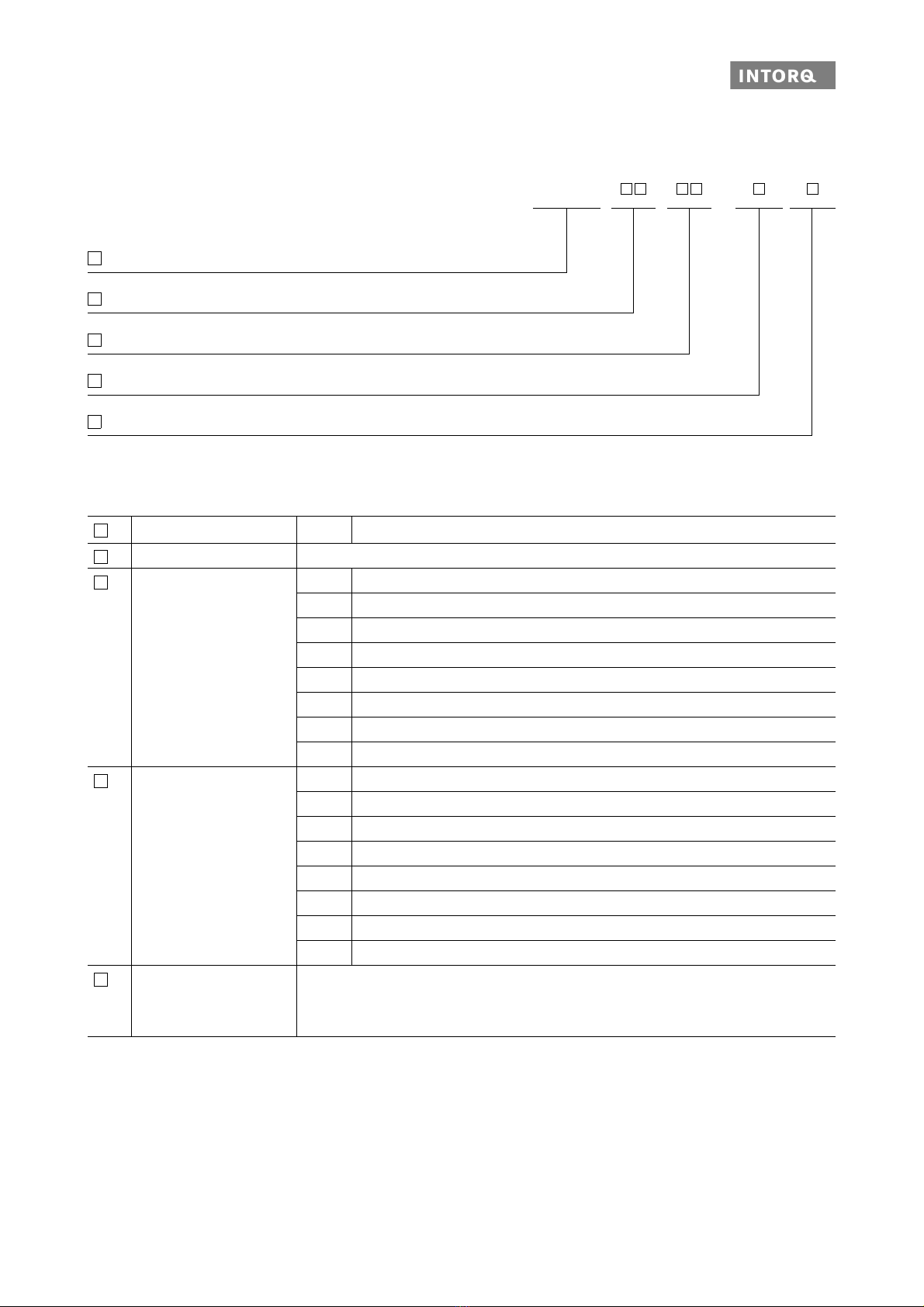

1 Preface and general information............................................................................................................................5

1.1 About these Operating Instructions................................................................................................................5

1.2 Terminology used...........................................................................................................................................5

1.3 Abbreviations used.........................................................................................................................................5

1.4 Conventions in use.........................................................................................................................................7

1.5 Scope of delivery............................................................................................................................................7

1.6 Disposal .........................................................................................................................................................7

1.7 Drive systems.................................................................................................................................................7

1.8 Legal regulations............................................................................................................................................8

2 Safety instructions ..................................................................................................................................................9

2.1 Personnel responsible for safety....................................................................................................................9

2.2 General safety instructions.............................................................................................................................9

2.3 Application range of the CBC.......................................................................................................................10

2.4 Safety instructions and notices....................................................................................................................10

3 Technical specifications.......................................................................................................................................12

3.1 Product description ......................................................................................................................................12

3.2 Switching times............................................................................................................................................14

3.3 Rated data....................................................................................................................................................15

3.4 Switching energy / operating frequency.......................................................................................................16

4 Mechanical installation .........................................................................................................................................17

4.1 Assembly......................................................................................................................................................17

4.2 Installation....................................................................................................................................................17

4.3 Disassembly ................................................................................................................................................18

4.4 Disassembly of complete drive cover...........................................................................................................19

4.5 Assembly......................................................................................................................................................27

5 Electrical installation.............................................................................................................................................28

5.1 Electrical connection....................................................................................................................................28

6 Maintenance and repair ........................................................................................................................................30

6.1 Inspection intervals......................................................................................................................................30

6.2 Spare-parts list.............................................................................................................................................33