5 Mechanical installation ............................................................................................................................................26

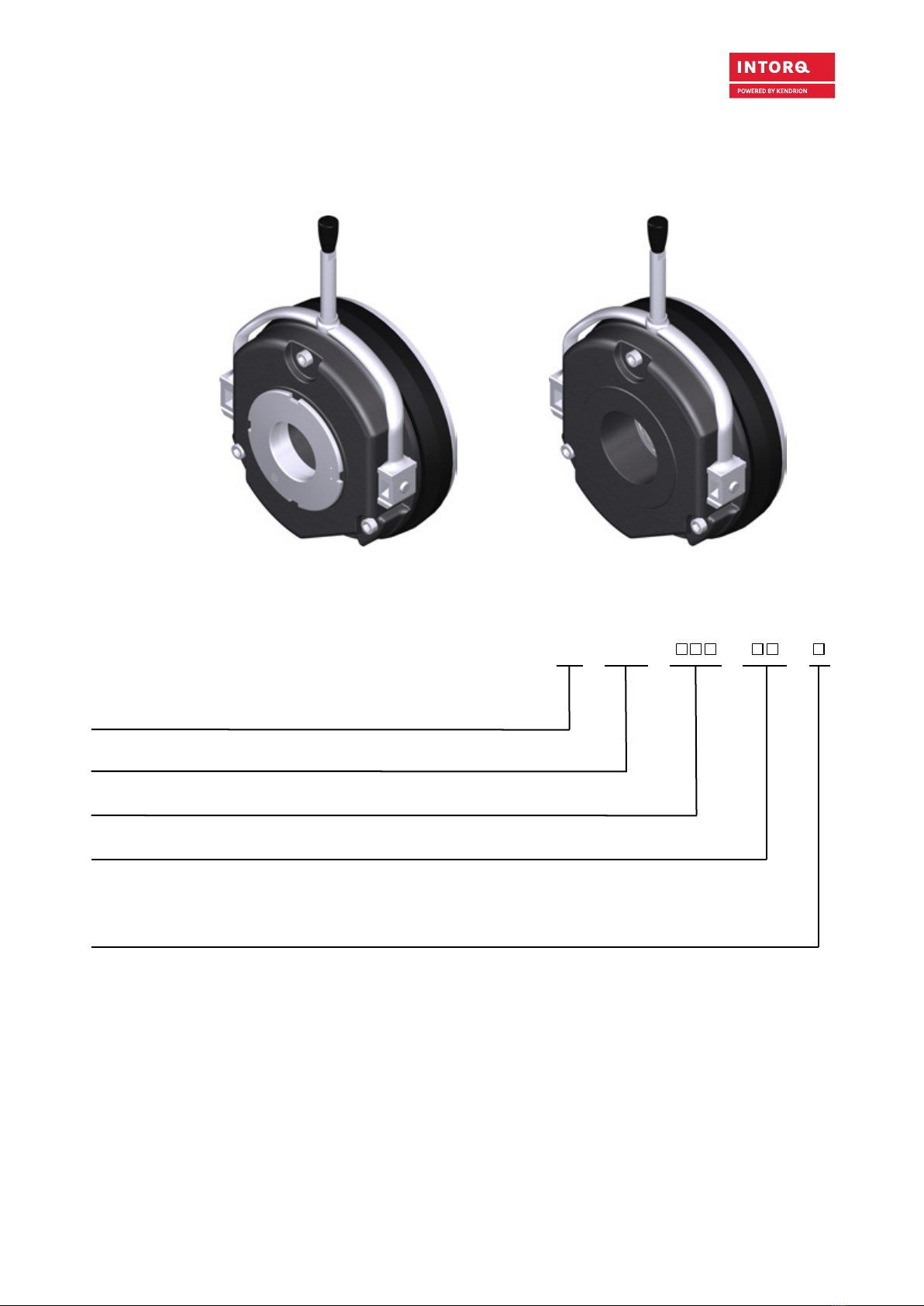

5.1 Design of end shield and shaft ...........................................................................................................................26

5.2 Tools...................................................................................................................................................................27

5.3 Preparing the installation ....................................................................................................................................27

5.4 Installing the hub onto the shaft..........................................................................................................................28

5.5 Mounting the brake.............................................................................................................................................29

5.6 Installing the friction plate (optional) ...................................................................................................................32

5.7 Cover ring assembly ...........................................................................................................................................33

5.8 Mounting the hand-release (retrofitting)..............................................................................................................34

6 Electrical installation................................................................................................................................................35

6.1 Electrical connection...........................................................................................................................................35

6.2 AC switching at the motor – extremely delayed engagement.............................................................................36

6.3 DC switching at the motor – fast engagement....................................................................................................37

6.4 AC switching at mains – delayed engagement...................................................................................................38

6.5 DC switching at mains – fast engagement .........................................................................................................39

6.6 Minimum bending radius for the brake connection cable ...................................................................................40

7 Commissioning and operation ................................................................................................................................41

7.1 Possible applications of the Kendrion INTORQ spring-applied brake ................................................................41

7.2 Function checks before initial commissioning.....................................................................................................42

7.2.1 Function check of the brake ...................................................................................................................42

7.2.2 Release / voltage control........................................................................................................................42

7.2.3 Testing the hand-release functionality....................................................................................................43

7.3 Commissioning ...................................................................................................................................................44

7.4 Operation............................................................................................................................................................44

7.4.1 Brake torque reduction (for the optional adjustable braking torque) ......................................................45

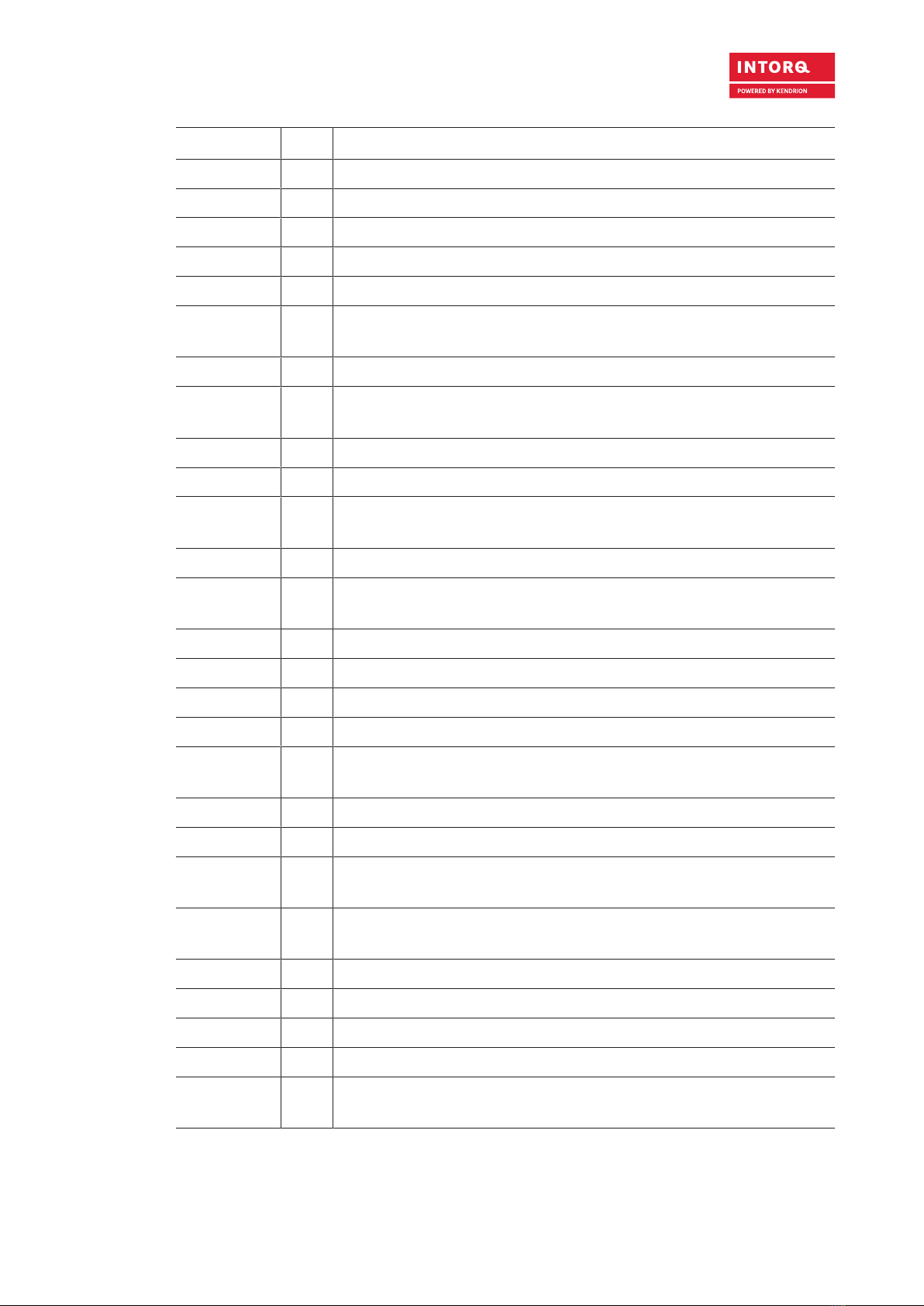

8 Maintenance and repair............................................................................................................................................46

8.1 Wear of spring-applied brakes............................................................................................................................46

8.2 Inspections..........................................................................................................................................................47

8.2.1 Maintenance intervals ............................................................................................................................47

8.3 Maintenance .......................................................................................................................................................48

8.3.1 Brake testing ..........................................................................................................................................48

8.3.2 Checking the air gap ..............................................................................................................................48

8.3.3 Release / voltage....................................................................................................................................49

8.3.4 Adjusting the air gap...............................................................................................................................49

8.3.5 Checking the rotor thickness..................................................................................................................50

8.3.6 Replacing the rotor.................................................................................................................................50

8.4 Spare parts list....................................................................................................................................................51

9 Troubleshooting and fault elimination....................................................................................................................52

Kendrion INTORQ | BA 14.0225 | 05/2022 5