5

14140 NE 200th St.

Woodinville, WA 98072

1.425.398.8282

www.ioline.com

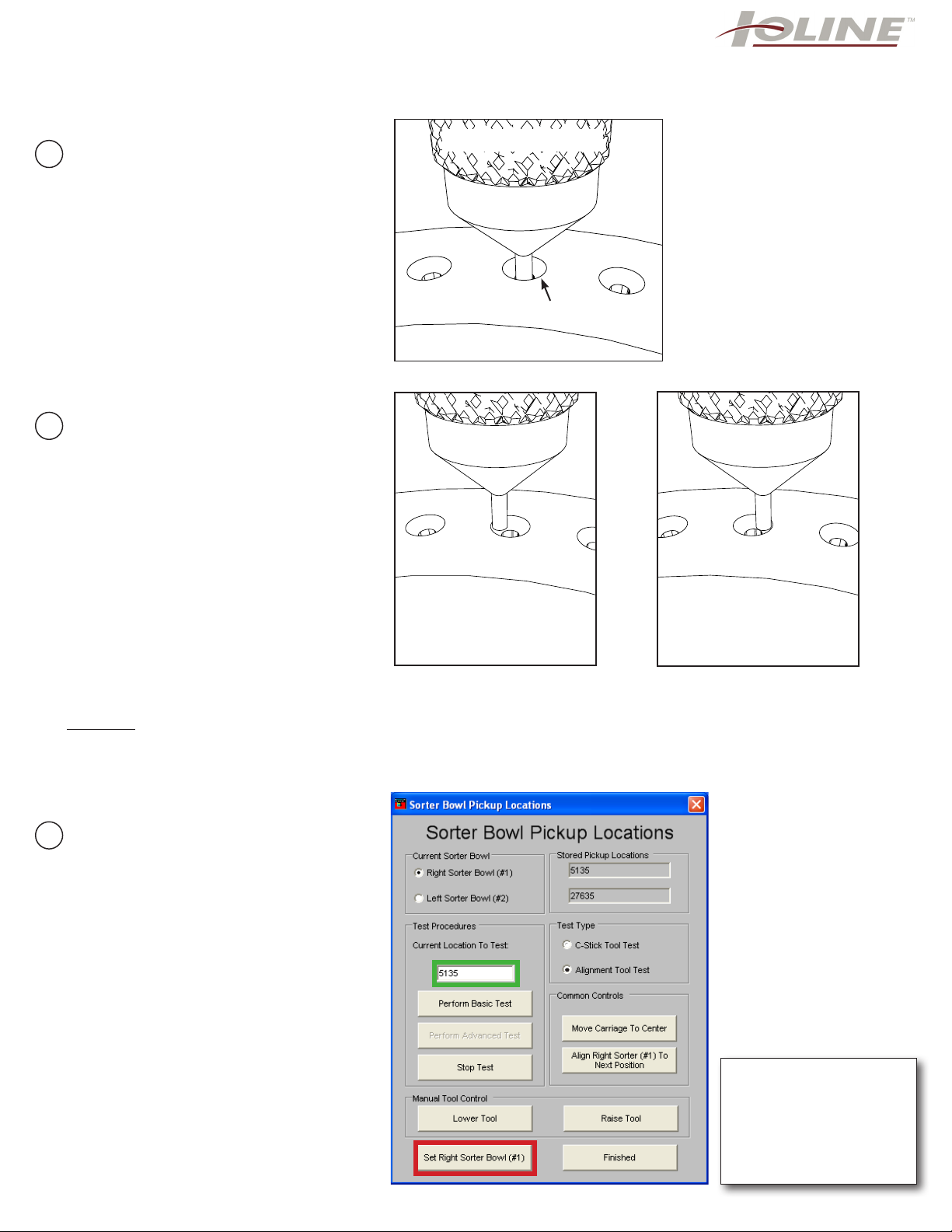

When the tip is centered on the wheel pocket, tighten the two Phillips screws on

either side of the adjustment nut with medium force. CAUTION: Do not overtighten

the screws as this can damage the bowl assemblies.

IMPORTANT: Repeat this process for BOTH sorter bowls, especially when any compo-

nents are changed in the Carriage (Y) axis.

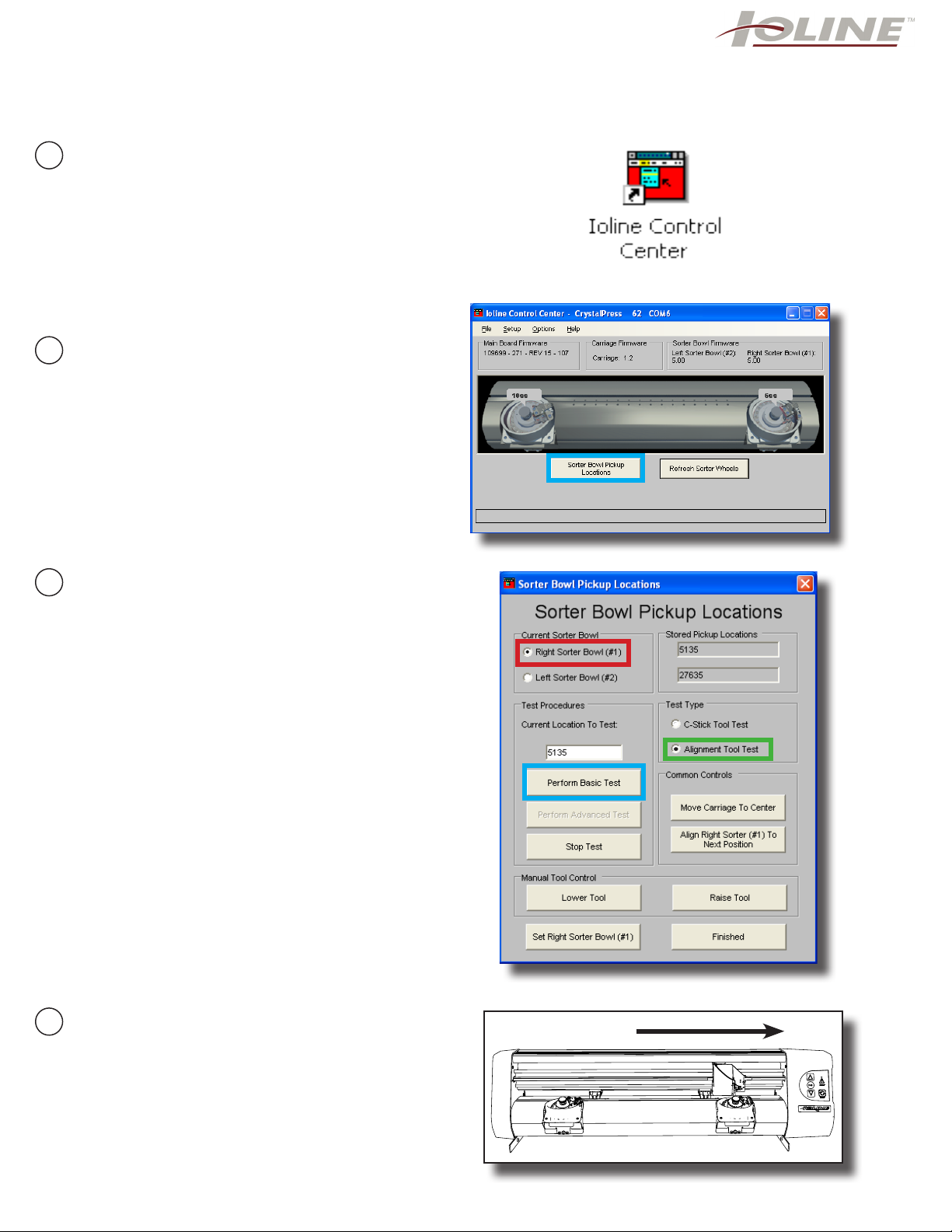

If the alignment tip looks like this:

Loosen the two screws on either side

of the nut by equal amounts so that the

Sorter Bowl will adjust inward. Refer to

the chart on the right to estimate how

much to the rotate the screws. Lightly

tighten the nut the same amount the

screws were loosened to move the bowl

inward. Stop tightening when the tip

stops moving.

View looking

from the right

side of the

bowl

Front of machine

View looking

from the right

side of the

bowl

Front of machine

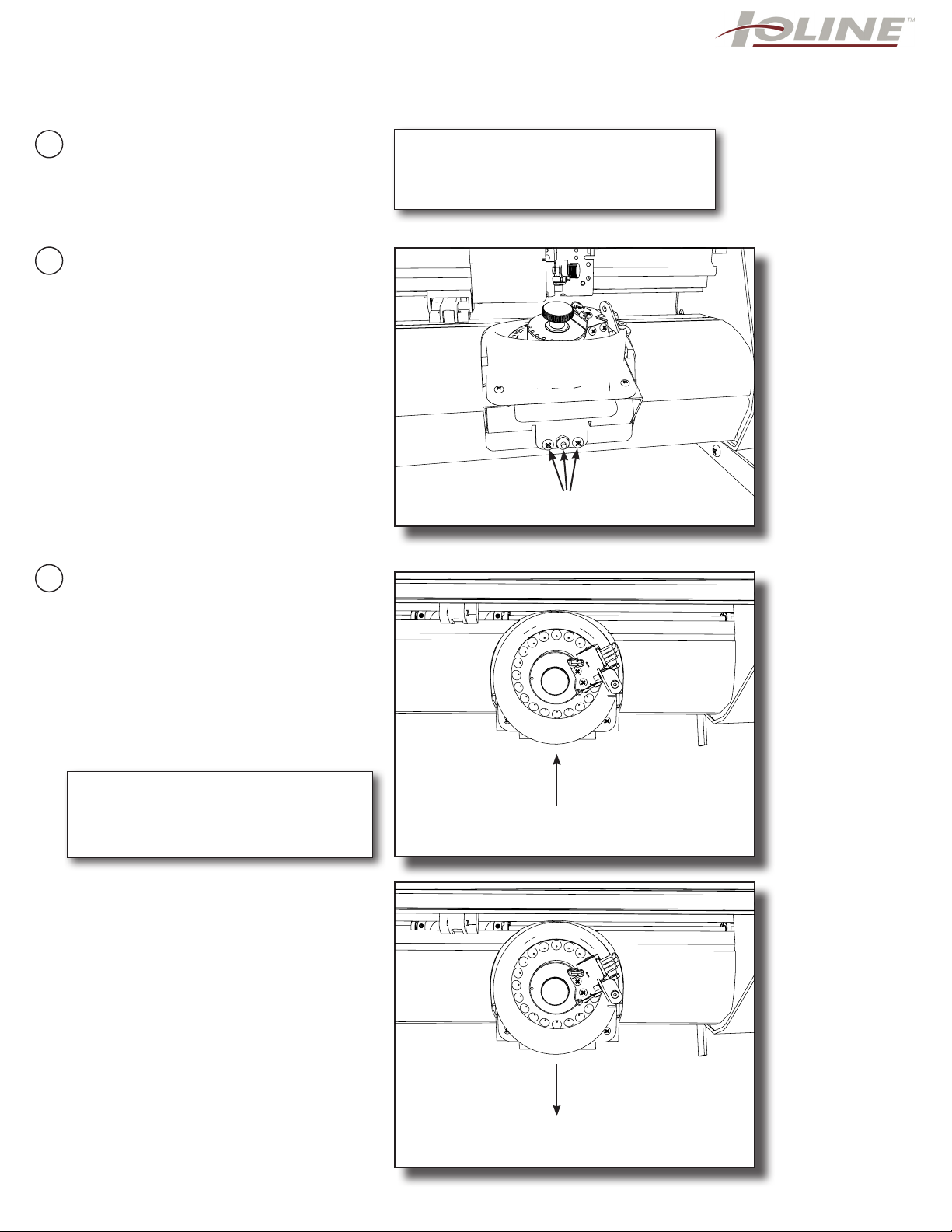

Turning the front sorter

bowl nut and screws

by these amounts will

result in the associated

bowl movement:

1/4 turn = .008”

1/2 turn = .016”

1 turn = .032”

If problems arise or

you need further as-

sistance, contact Ioline

Customer Support at

1.425.398.8282 or at

www.ioline.com

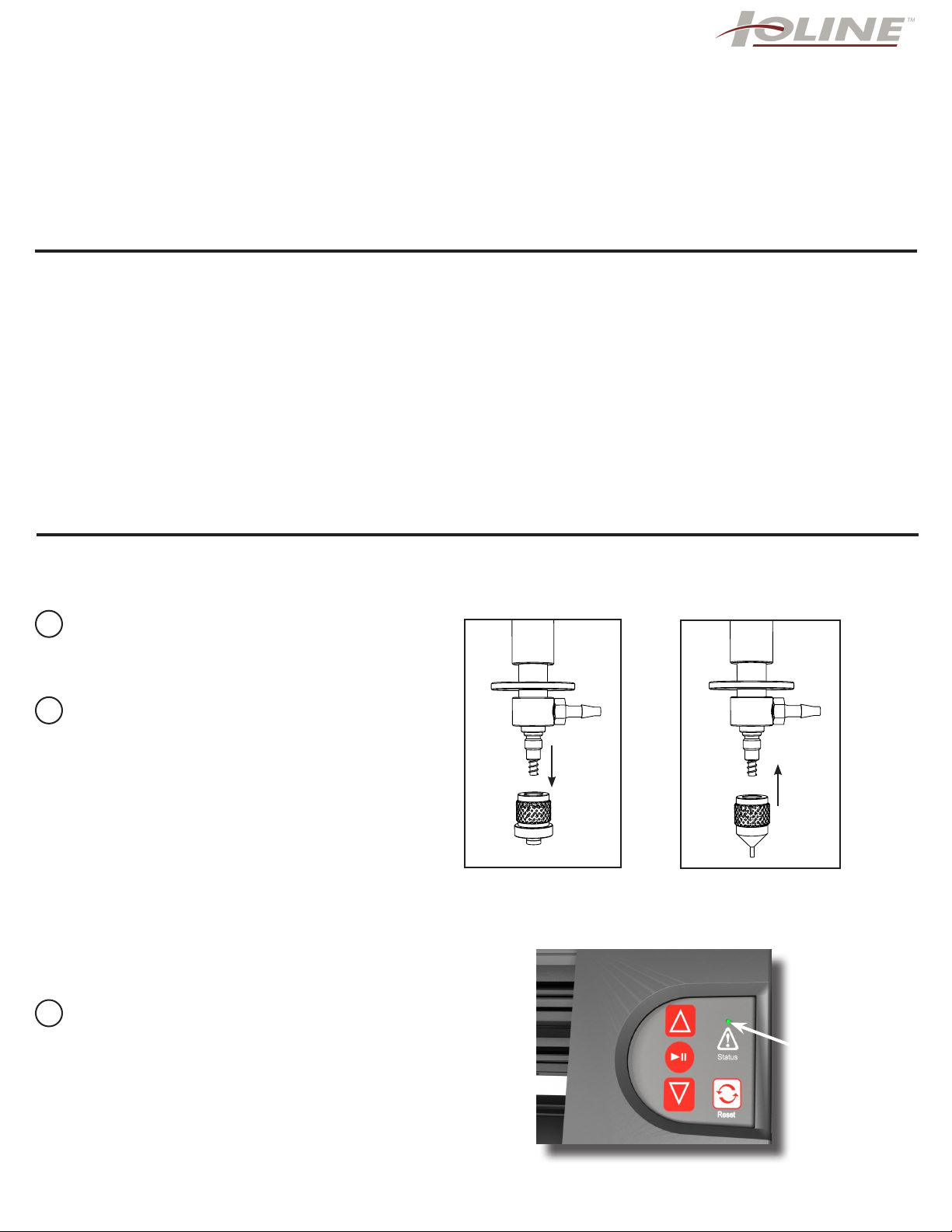

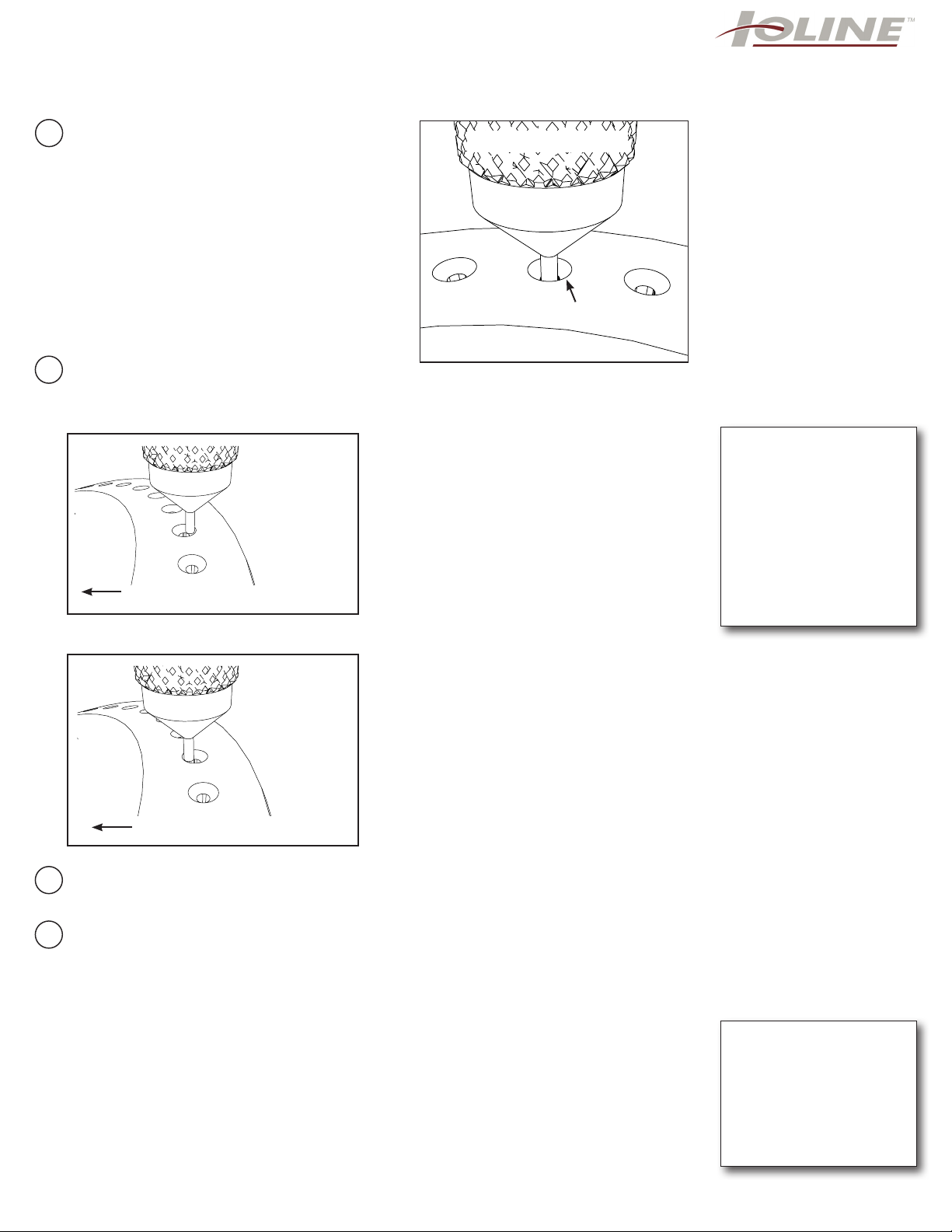

4Lower the Alignment Tool tip near the

Sorter Wheel by lightly pressing down

on the C-Stick Carriage Clamp with your

nger. Look at the pin at the end of

the Alignment Tool. If the pin does not

go down in the hole, use the diagrams

below to determine which direction

(front or back) the Sorter Bowl needs to

move so that the pin will line up with

the hole. Wheel

Alignment Tool Tip

Rhinestone Pocket

HINT: Check the Side to Side (Carriage Y) adjustment after the Front to Back (Sheet

X) adjustment process is complete. Perform this check after installing the normal C-

Stick tip since it may vary slightly from the Alignment Tool tip. You may have to make

small adjustments to compensate.

Adjusting the Bowls (X axis):

If the alignment tip looks like this:

Adjust the bowls using one of the two

methods shown below.

5

Loosen the nut on the front of the

Sorter Bowl so that it will adjust outward.

Refer to the chart above to the right to

estimate how much to the rotate the

nut. Lightly tighten the two screws the

same amount the nut was loosened to

move the bowl outward. Stop tightening

when the tip stops moving.

Repeat Steps 4-5 to make more adjustments as needed until the tip is centered Front

to Back on the wheel pocket.

6

7