1. p. 2

System Overview

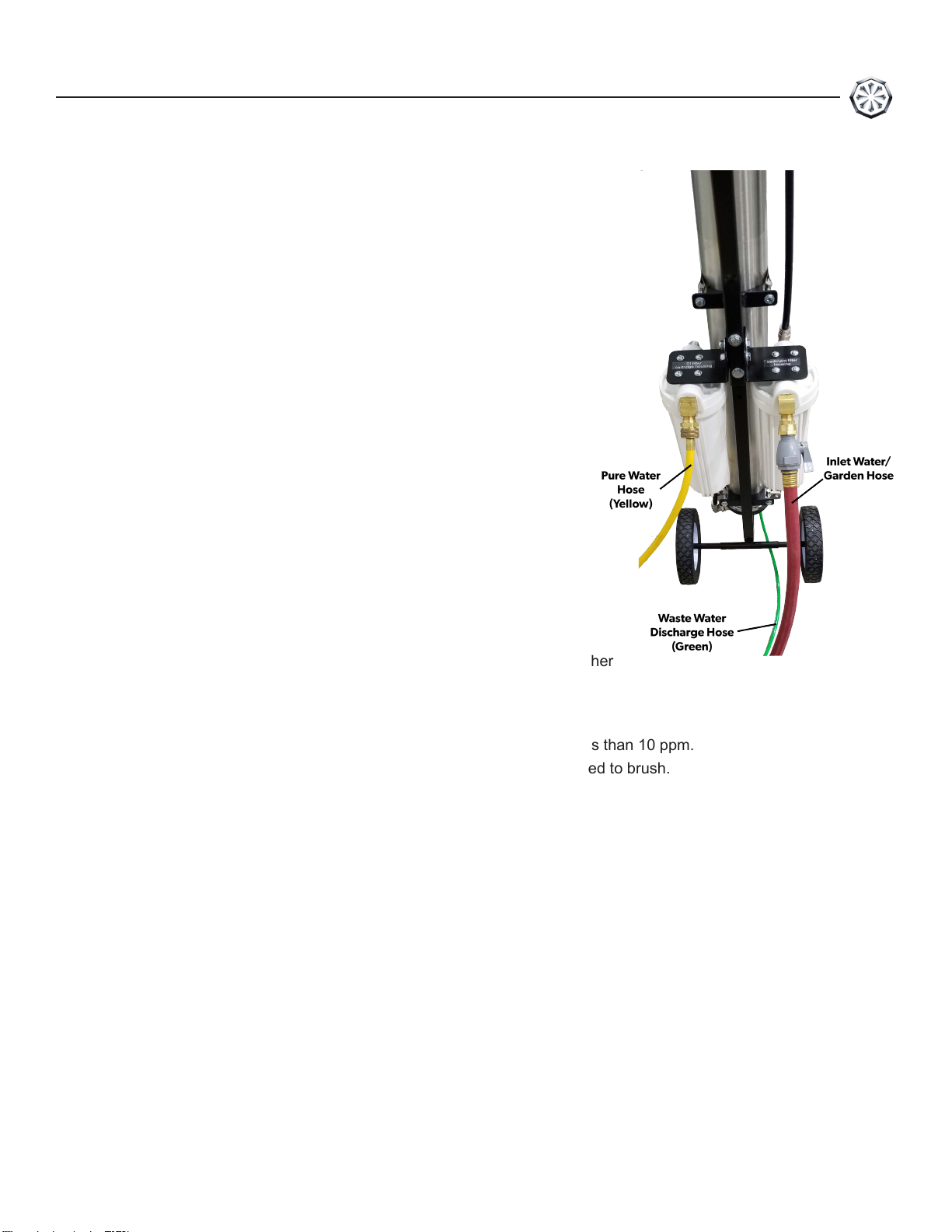

The following information is provided to help you understand how the system

operates.

•Pure water production volume on any Reverse Osmosis system is temperature

dependant.

oColder feed water, i.e. the late fall, winter and early spring will produce a lower

volume (gpm) of pure water.

oWarmer water, i.e. late spring, summer and early fall will produce a higher volume

(gpm) of pure water.

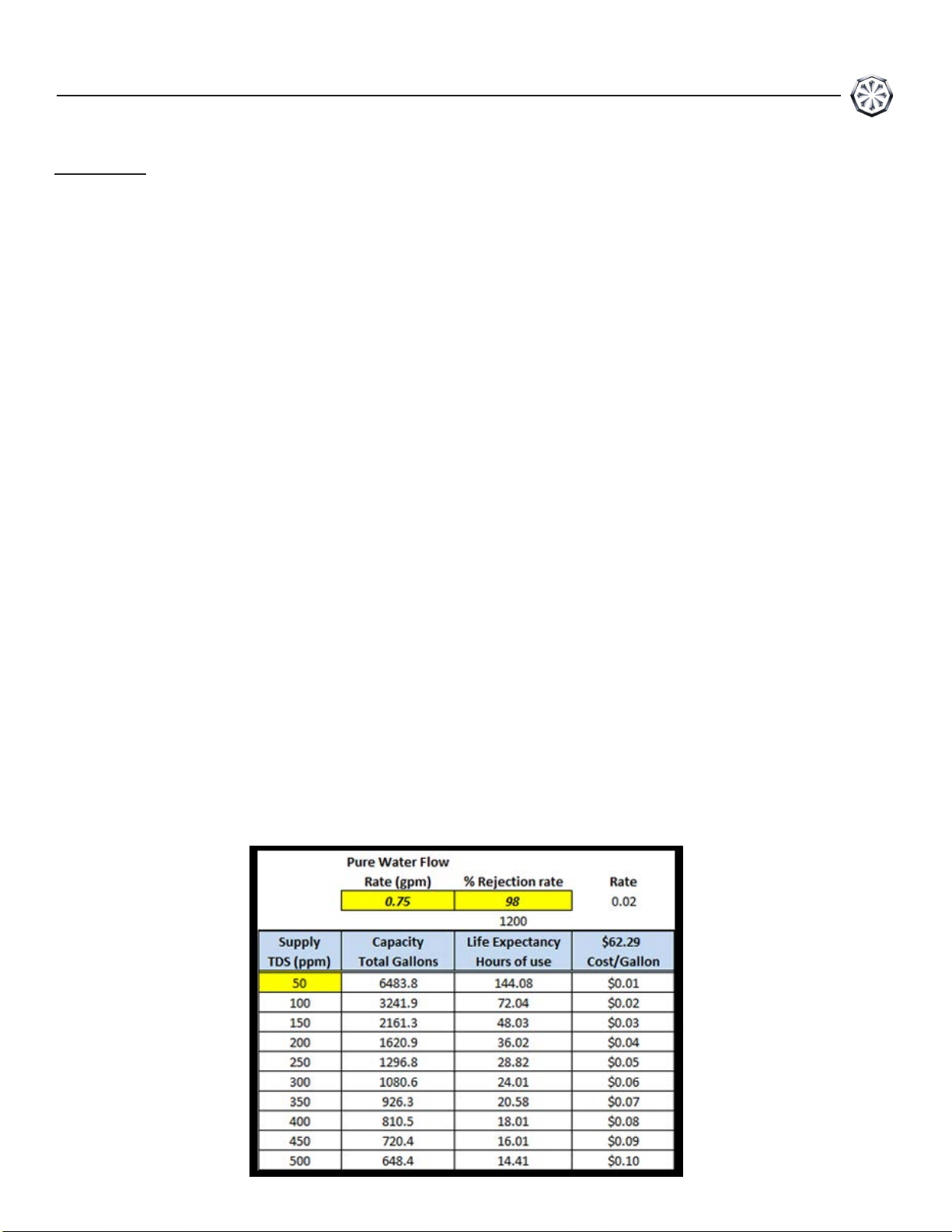

•The reverse osmosis (RO) portion of this system will remove 94% to 98% of the total

dissolved solids (TDS) from the feed water. The amount that is removed depends on

several factors such as water temperature, pressure,water quality, care of membrane and

outside conditions. New membranes may take some time to soak and provide more

efficient removal of dissolved solids.

oExample: if your supply water is 200 parts per million (200 ppm) at a removal rate

of 98% then the RO product water will be 4 ppm. If your supply water is 700 ppm,

then the RO product water will be 14 ppm.

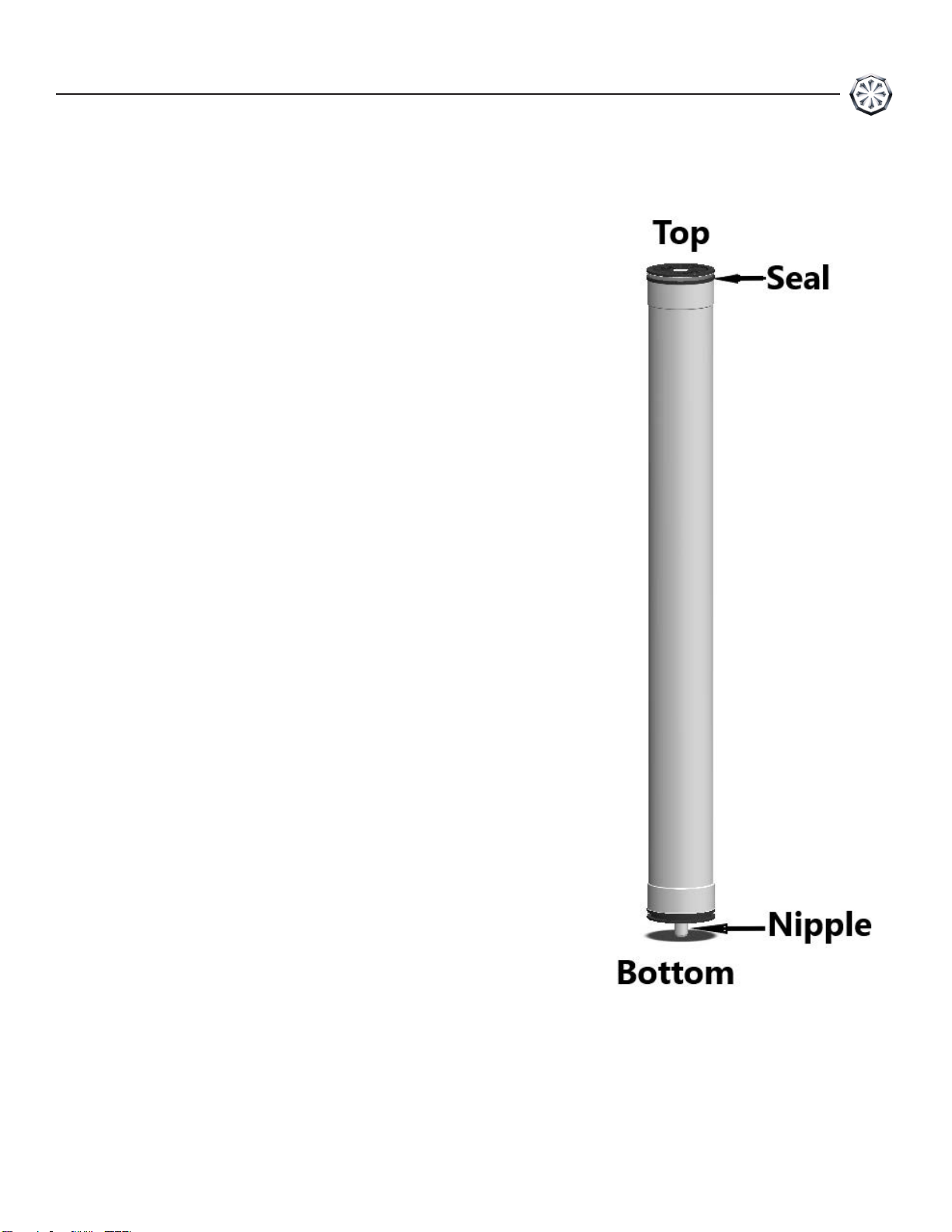

•The RO product water then flows through the deionizing (DI) resin which removes the

balance of the dissolved solids, giving you water at 0 ppm TDS. The DI resin acts like

sponge that absorbs dissolved solids. Once it is full, it has to be replaced.

•The Carbon/Sediment filter removes all solid particles larger than 5 microns in size from

the feed water. In addition, it removes the chlorine from the feed water. Chlorine will

damage the RO membranes and make them ineffective. The carbon block can only hold a

finite amount of chlorine. It must be replaced after 5,000 gallons of feed water have

passed through it or 30 hours.

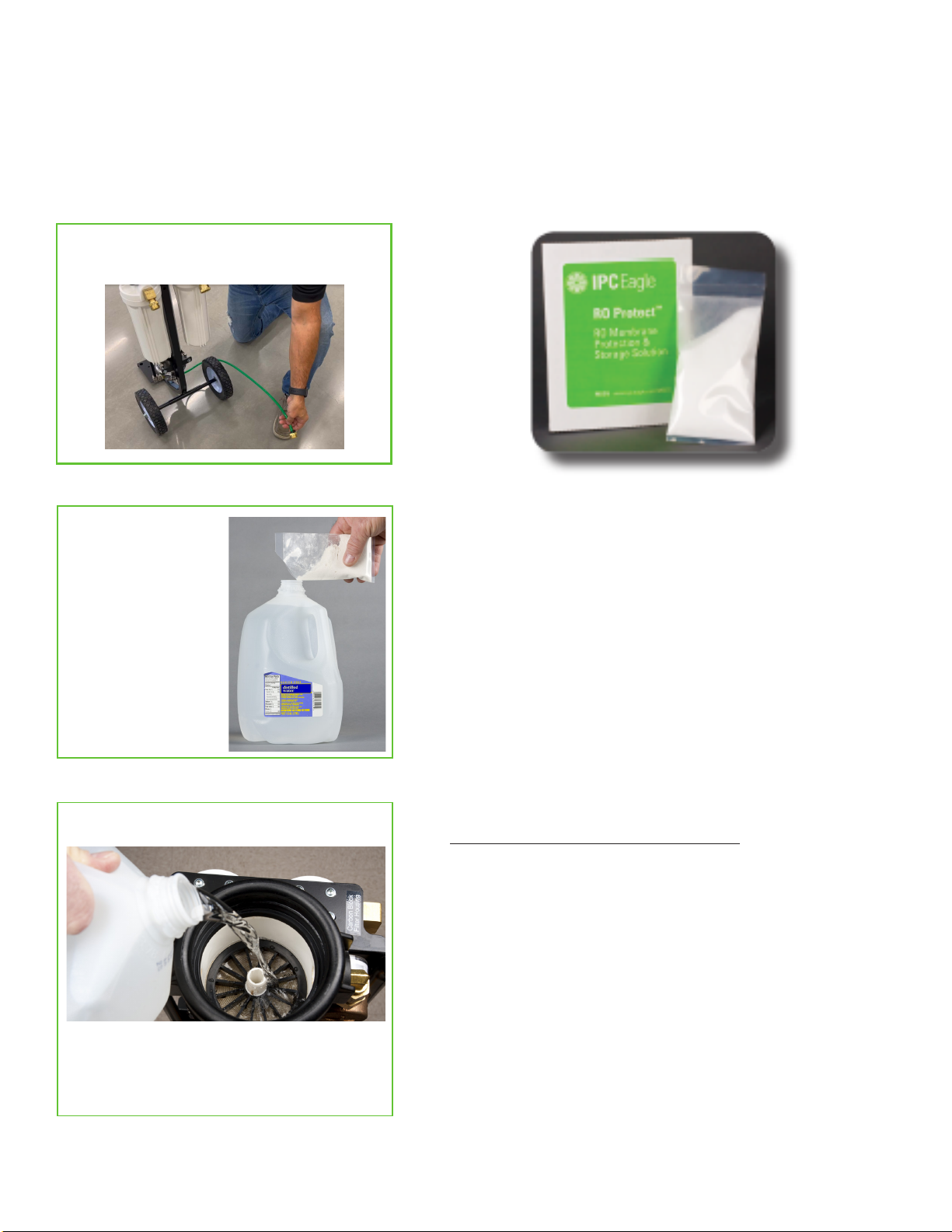

•Short term and long term storage is an important issue. The system must be protected

from algae and bacteria growth in the pressure vessels caused by stagnant water. The

membranes and DI resin must not be allowed to dry out either. Please see the Storage

section in this manual for proper instructions.

•The unit must be protected from freezing.