5

Pressurized hoses

Because the hoses are pressurized they can present a danger should the fluid escape due

to damage, worn parts or general miss-use. Escaping fluid can splash or spray operator,

causing serious bodily injury and/or damage to equipment and property. Ensure that the

hoses do not leak or rupture due to wear, misuse or damage.

Before each use, ensure that the fluid couplings are tight and all clips/pins/plugs are

secured. Inspect the entire length of hose for wear, cuts, abrasions, bulging cover and/or

loose connections. These conditions may cause the hose to fail and result in splashing or

spraying of chemicals on the skin or in the eyes of operator and cause serious injury

and/or property damage.

Pressure specification

The maximum working pressure of this equipment for fluids and air is 180 psi (12.5bar).

Ensure all equipment and accessories used with this pump are rated to withstand the

maximum working pressure of this pump. Never exceed the maximum working pressure of

the pump, hose lines or any other components attached to the pump itself.

Procedure for pressure relief

In order to avoid the risk of serious injury to operators from splashing/spraying chemicals,

the following safety procedures should be used. This procedure should be used when

shutting down the pump, performing general maintenance, repairing a pump or other

components of the system, replacing components or when pumping operation is ceased.

1. Close the air valve to the pump.

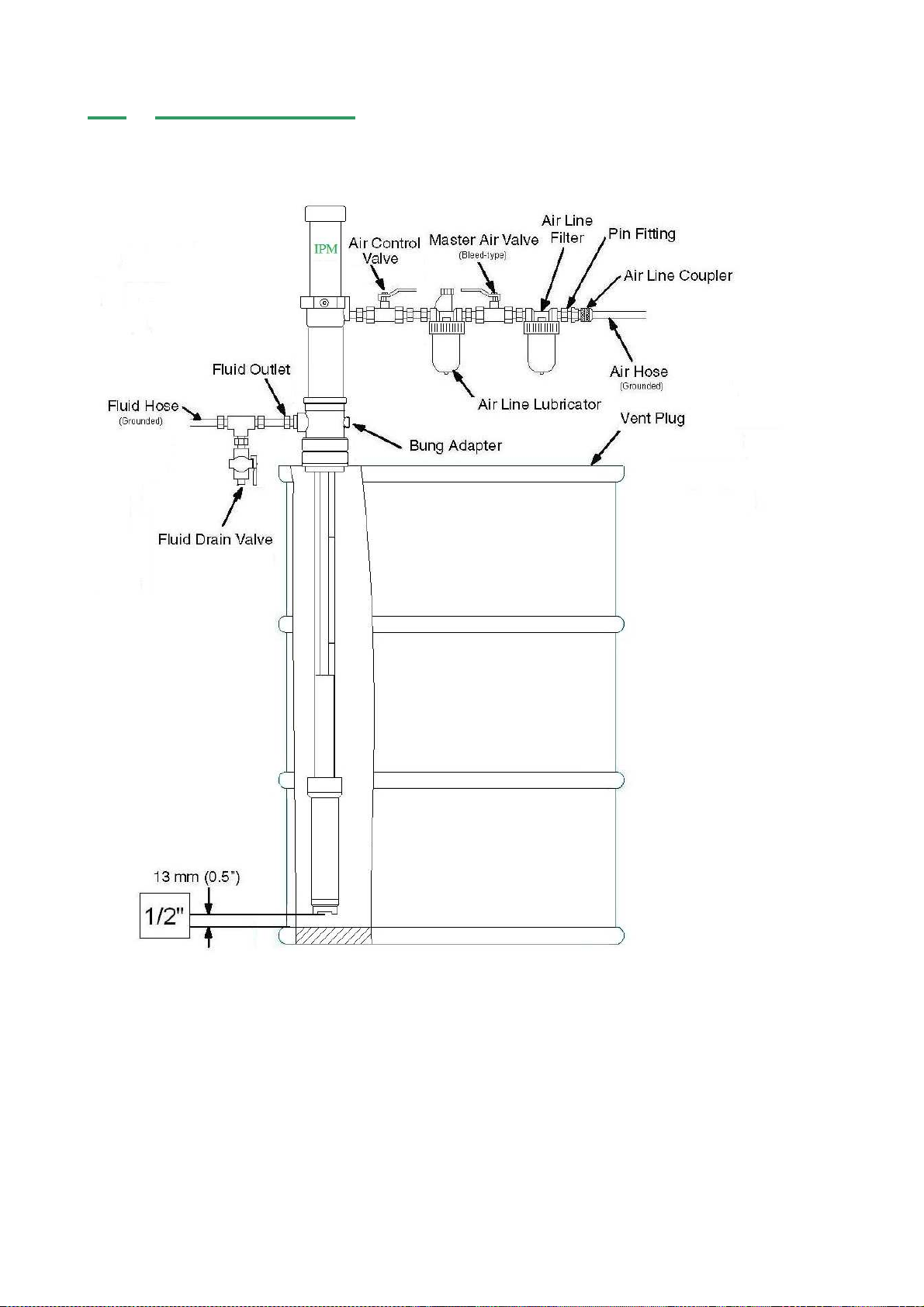

2. Use the air bleed down valve (see INSTALLATION, page 8) to relieve the air

pressure in the system.

3. Relieve the fluid pressure by holding a grounded metal pail in contact with the metal

part of the fluid dispense valve and slowly opening the valve.

4. With a container ready to catch the fluid, open the drain valve (see INSTALLATION,

page 8).

5. It is a good practice to leave the drain valve open until it is time to dispense fluid

again.

If you are unsure that the fluid pressure has been relieved due to a blockage in a

component or a hose, carefully relieve the pressure by carefully loosening the hose end

coupling to allow the fluid pressure to escape slowly. After the pressure has been relieved,

the fitting can then be removed and any blockages removed.

Flush the pump before initiating operation

1. The pump is tested with lightweight DOP oil, which is left in to protect the pump

parts. If the fluid you are pumping may become contaminated by oil, flush oil from

pump with a compatible solvent before use. Follow the flushing instructions below.

2. When pumping fluids that set up or solidify, flush the system with a compatible

solvent as often as necessary to remove build-up of solidified chemicals in the

pump or hoses.