C. System Components

1. IPS M720 pH/ORP Controller

a. Allows automac monitoring of pH and ORP levels through

a simple, user-friendly interface, resulng in easier

management of water balance in swimming pools, spas, or

circulang water environments.

b. Can be easily installed into your exisng pool environment

and equipment, or can be customized to your needs.

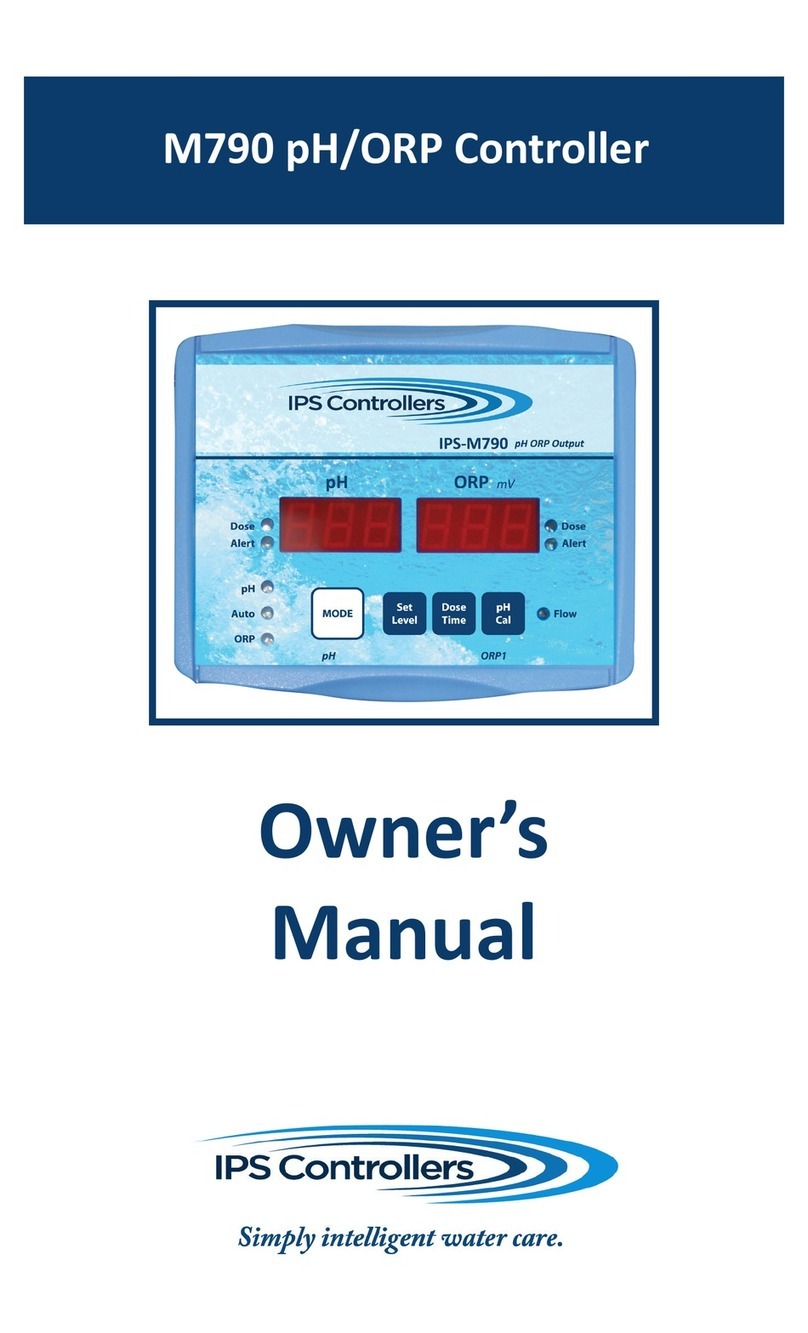

c. Monitors and displays the pH and ORP levels using LEDs

and digital readouts on the front panel.

In addion, ve separate funcon buons allow simple

pushbuon control of these individual parameters:

1) Mode - Auto or pH Standby (programming),

2) Set Level - pH level to be maintained,

3) Dose Timer - Timed or Connuous feed modes,

4) Delay Time - Delay period aer each Dose Time,

5) pH Cal - pH calibraon.

d. When the pH level rises above (acid feed) or falls below

(base feed) the set level, the controller will acvate the

chemical feeder for the set dose me. Then the set delay

me will occur. This dose and delay me will occur unl

the set level is reached.

e. When the ORP (sanizer) level reaches the set level, the

controller will acvate the chemical feeder for the set dose

me. Then the set delay me will occur. This dose and

delay me will occur unl the set level is reached.

2. Flow Cell with Flow Switch

a. An injecon-molded ow cell with integrated ow-switch

houses the pH and ORP sensors, and partners with the

M720 controller to monitor the pH and ORP levels in the

water.

4

M720 pH/ORP Controller Owner’s Manual