Summary

1. General information ................................................................................................................ - 1 -

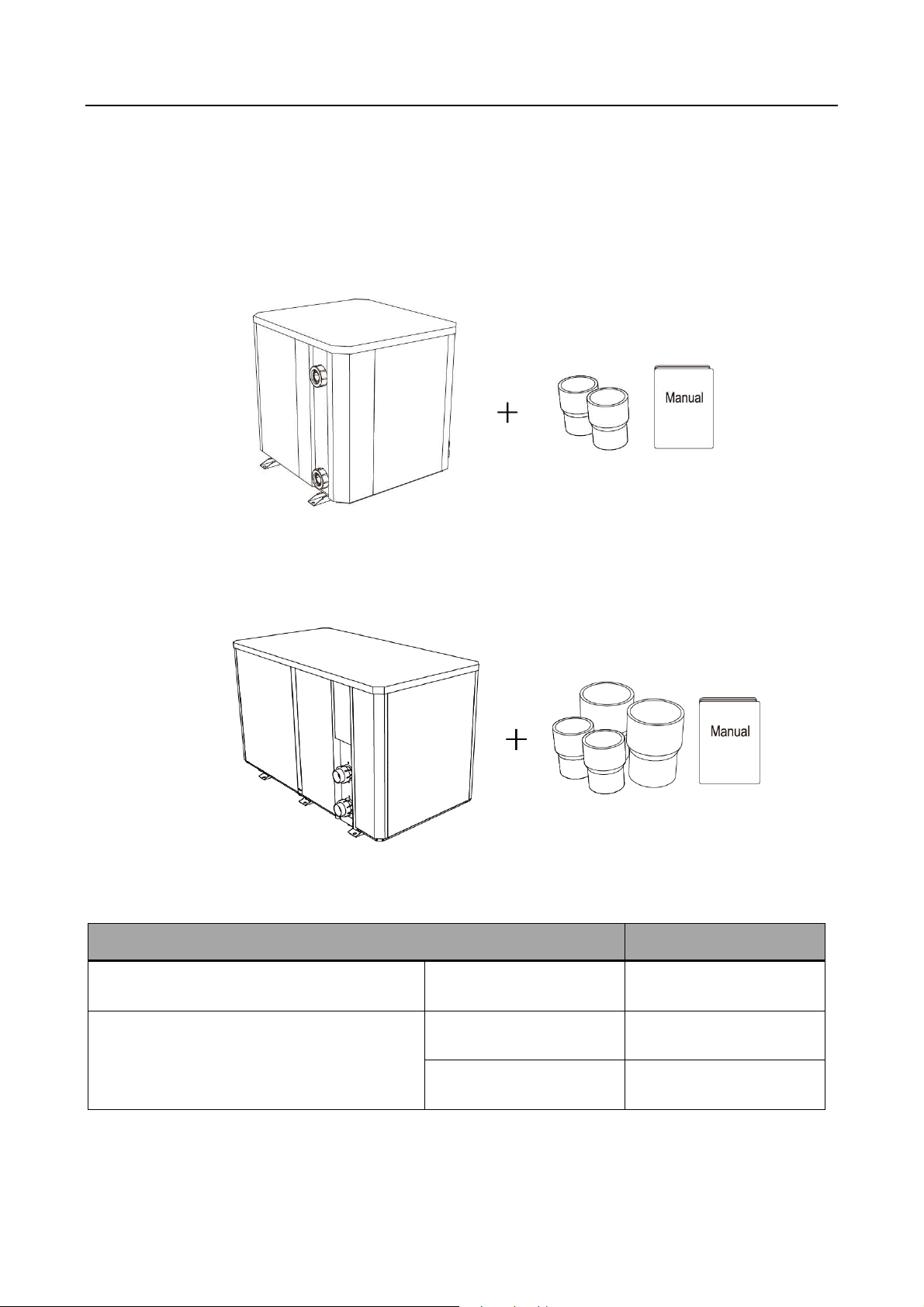

1.1. ontents .............................................................................................................................. - 1 -

1.2. Operating conditions and range ........................................................................................... - 1 -

1.3. Advantages of different modes ............................................................................................. - 2 -

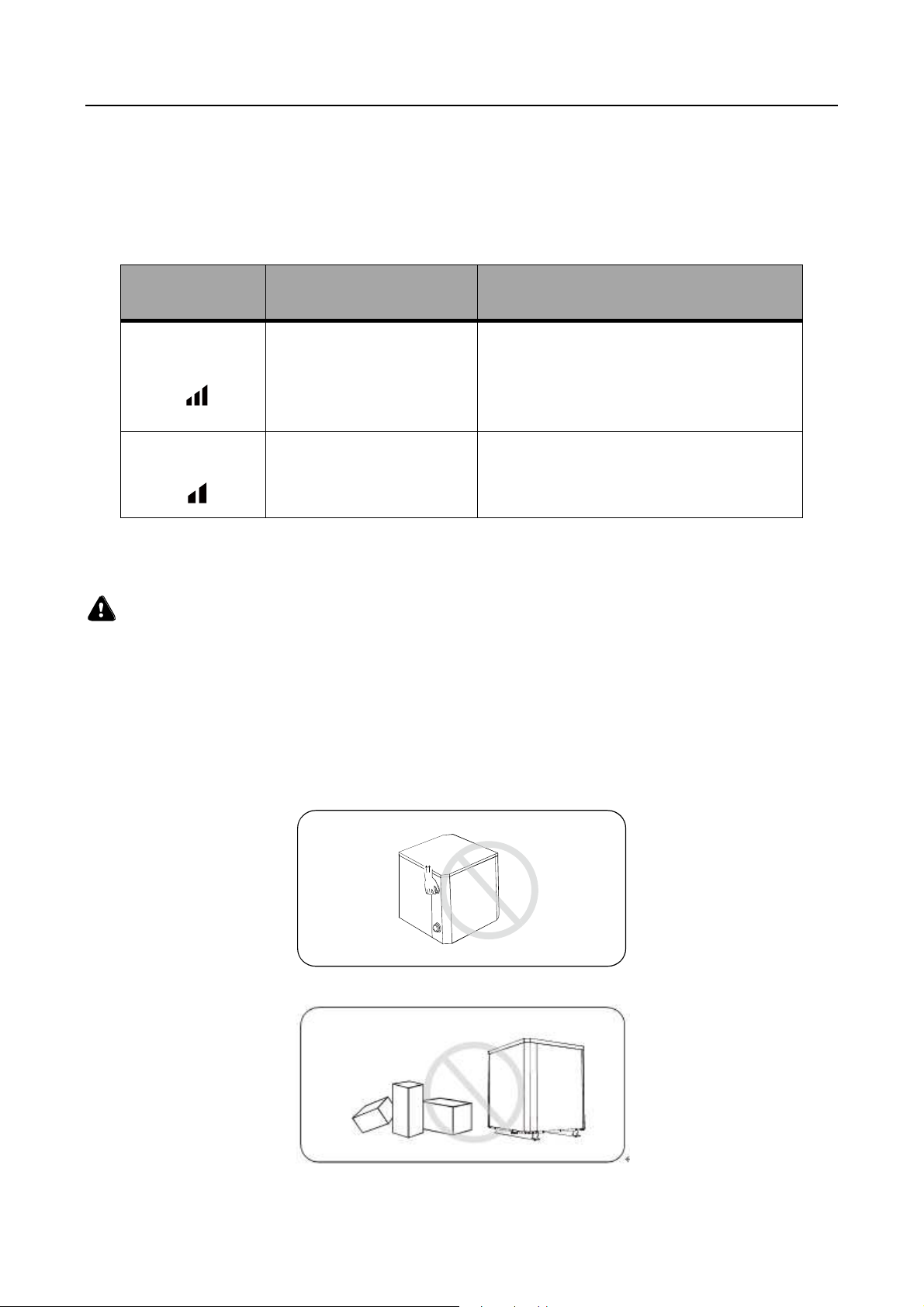

1.4. Kind reminder ....................................................................................................................... - 2 -

2. Operations .............................................................................................................................. - 4 -

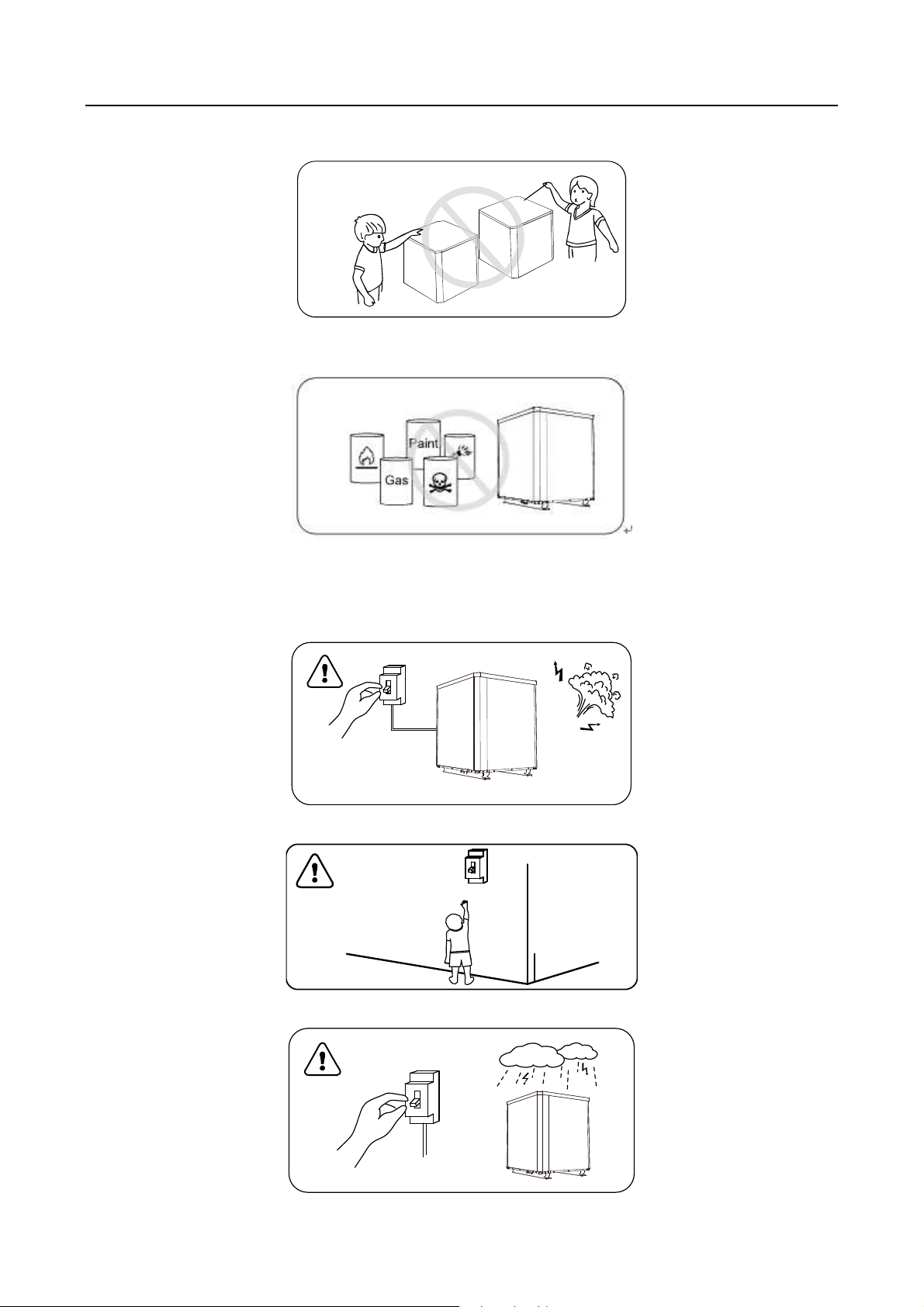

2.1. Notice before using .............................................................................................................. - 4 -

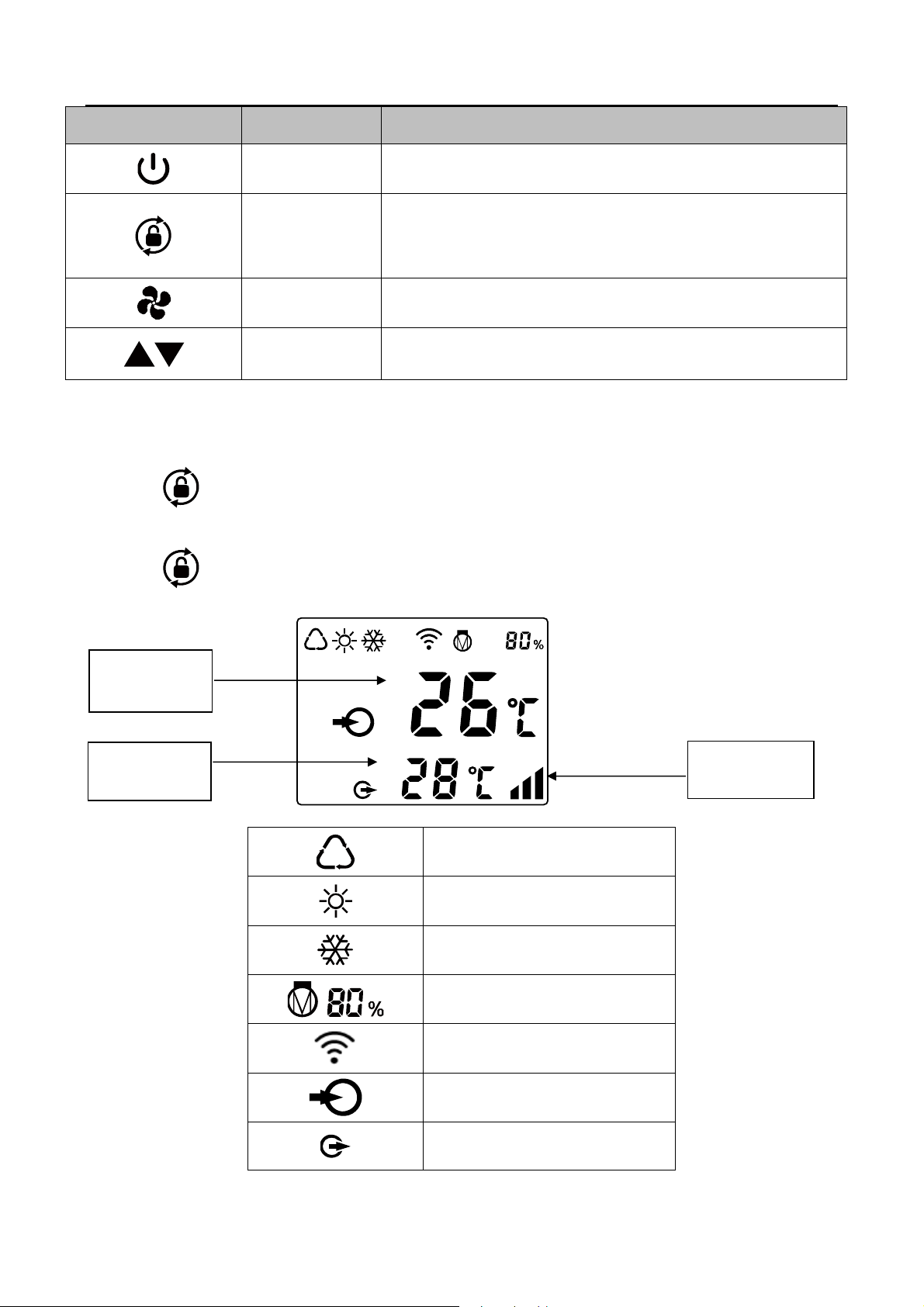

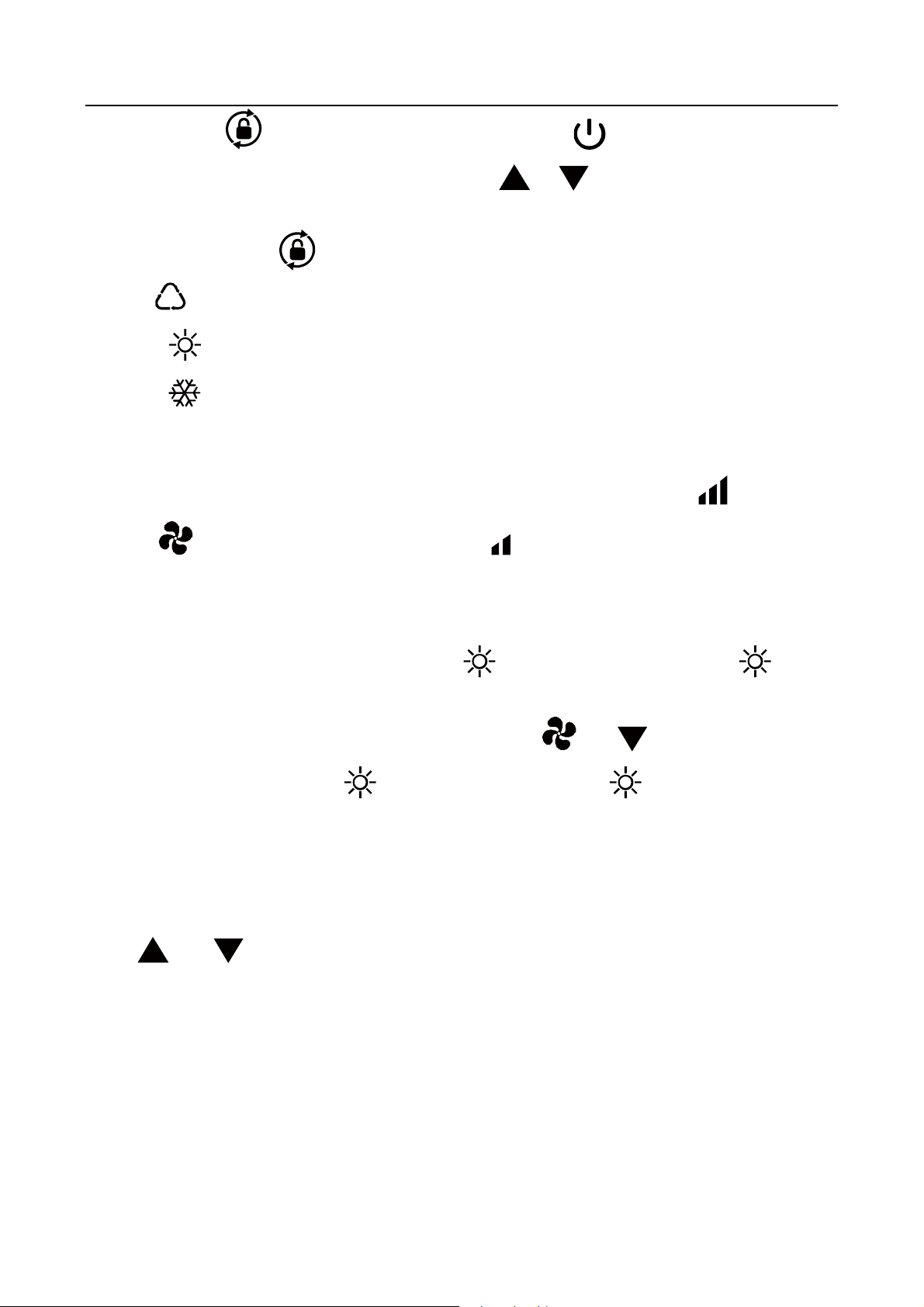

2.2. Operation instructions .......................................................................................................... - 4 -

2.3. Daily maintenance and winterizing ....................................................................................... - 7 -

3. Technical specification ............................................................................................................ - 8 -

1. Transportation ......................................................................................................................... - 9 -

2. Installation and maintenance ................................................................................................. - 10 -

2.1. Notice before installation: ................................................................................................ - 10 -

2.2. Installation instruction ......................................................................................................... - 10 -

2.3. Trial after installation .......................................................................................................... - 15 -

2.4. Maintenance and winterizing .............................................................................................. - 16 -

3. Trouble shooting for common faults ...................................................................................... - 16 -

4. Failure code .......................................................................................................................... - 17 -

Appendix 1: Heating priority wiring diagram (Optional) .............................................................. - 18 -

5.

Wifi setting ............................................................................................................................. - 20 -

For users ……………………………………………………………………………….

r installers and professionals