RESIDENTIAL VEHICULAR GATE OPERATOR

CLASS I – A vehicular gate operator (or system) intended for use

in a home of one-to four single family dwelling, or a garage or

parking area associated therewith.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

CLASS II – A vehicular gate operator (or system) intended for use

in a commercial location or building such as a multi-family housing

unit (five or more single family units), hotel, garages, retail

store, or other building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

CLASS III – A vehicular gate operator (or system) intended for

use in an industrial location or building such as a factory or

loading dock area or other locations not intended to service the

general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR

CLASS IV – A vehicular gate operator (or system) intended for

use in a guarded industrial location or building such as an airport

security area or other restricted access locations not servicing

the general public, in which unauthorized access is prevented

via supervision by security personnel.

The IQ-500 is a residential/commercial swing gate operator

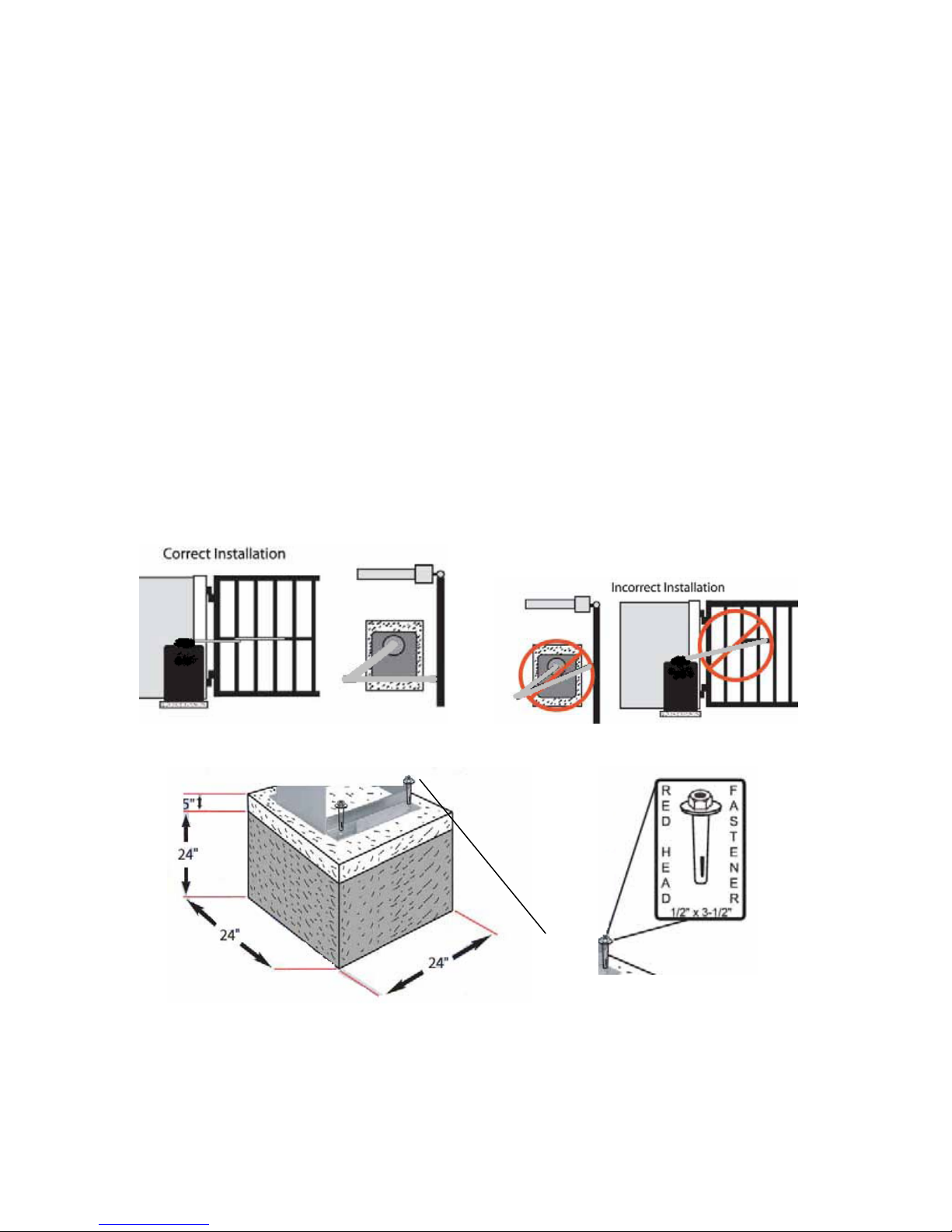

1) Install the gate operator only when:

•The operator is appropriate for the construction of the gate (see the

ASTM F2200 standard) and the usage UL Class of the gate,

•It is recommended that all openings of a swing gate are guarded or

screened from the bottom of the gate to a minimum of 4 feet (1.22

m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter

sphere from passing through the openings anywhere in the gate,

and in that portion of the adjacent fence that the gate covers in the

open position,

•Guarding is supplied for exposed hinges

•The bottom of the gate has been constructed so that a “raking”

action has been eliminated

•All exposed pinch points are eliminated or guarded

2) The operator is intended for installation only on gates used for vehicles.

Pedestrians must be supplied with a separate access opening.

3) The gate must be installed in a location so that enough clearance is supplied

between the gate and adjacent structures when opening and closing to reduce

the risk of entrapment. Swinging gates shall not open “into” public access areas.

4