www.iqualitrol.com, sales@iqualitrol.com 4

ServiceCall:+86‐13711988687

Two. Main Parameters

Model iRock-439T

Initial Test Force 3kgf (29.42N), 10kgf (98.07N)

Total Test Force 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N),

60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N)

Indenter Diamond Rockwell Indenter,Φ1.588mmBall Indenter

Loading Method Automatic (Loading/Dwell/Unloading)

Operation Automatic Rising and Homing,

One Key to Complete

Hardness Reading Touch Screen

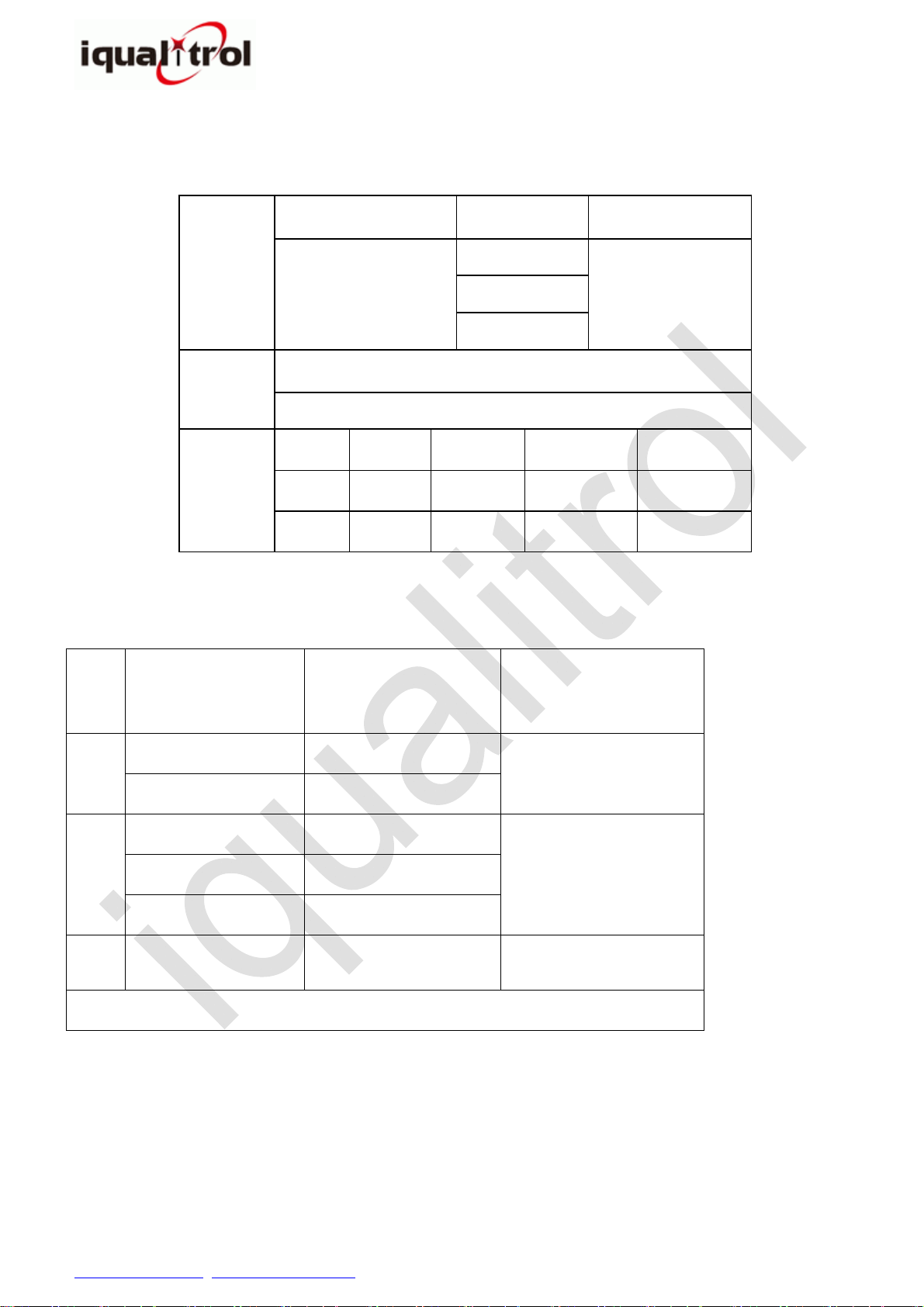

Test Scale

HRA, HRD, HRC, HRFW, HRBW, HRGW, HRHW, HREW, HRKW,

HRL, HRM, HRP, HRR, HRS, HRV

HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW,

HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y,

HR30Y, HR45Y

Conversion Scale

HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW,

HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HS,

HBW

Data Output Built-in Printer,RS232 Interface

Hardness Resolution 0.1HR

Dwell Time 0~99s

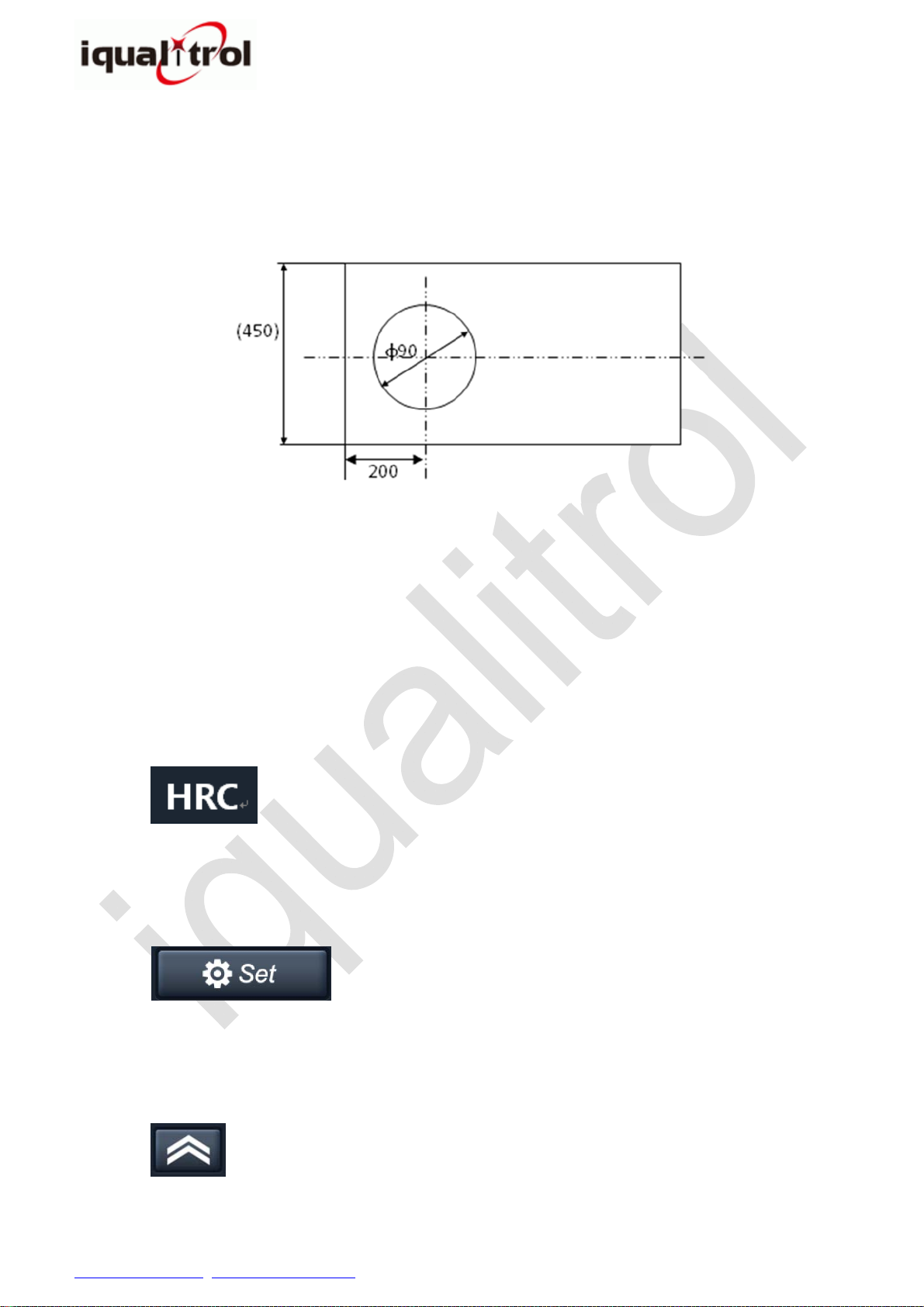

Max. Sample Height 310mm

Throat Depth 150mm

Power Supply AC220V,50Hz

Execute Standard ISO 6508,ASTM E18,JIS Z2245,GB/T 230.2

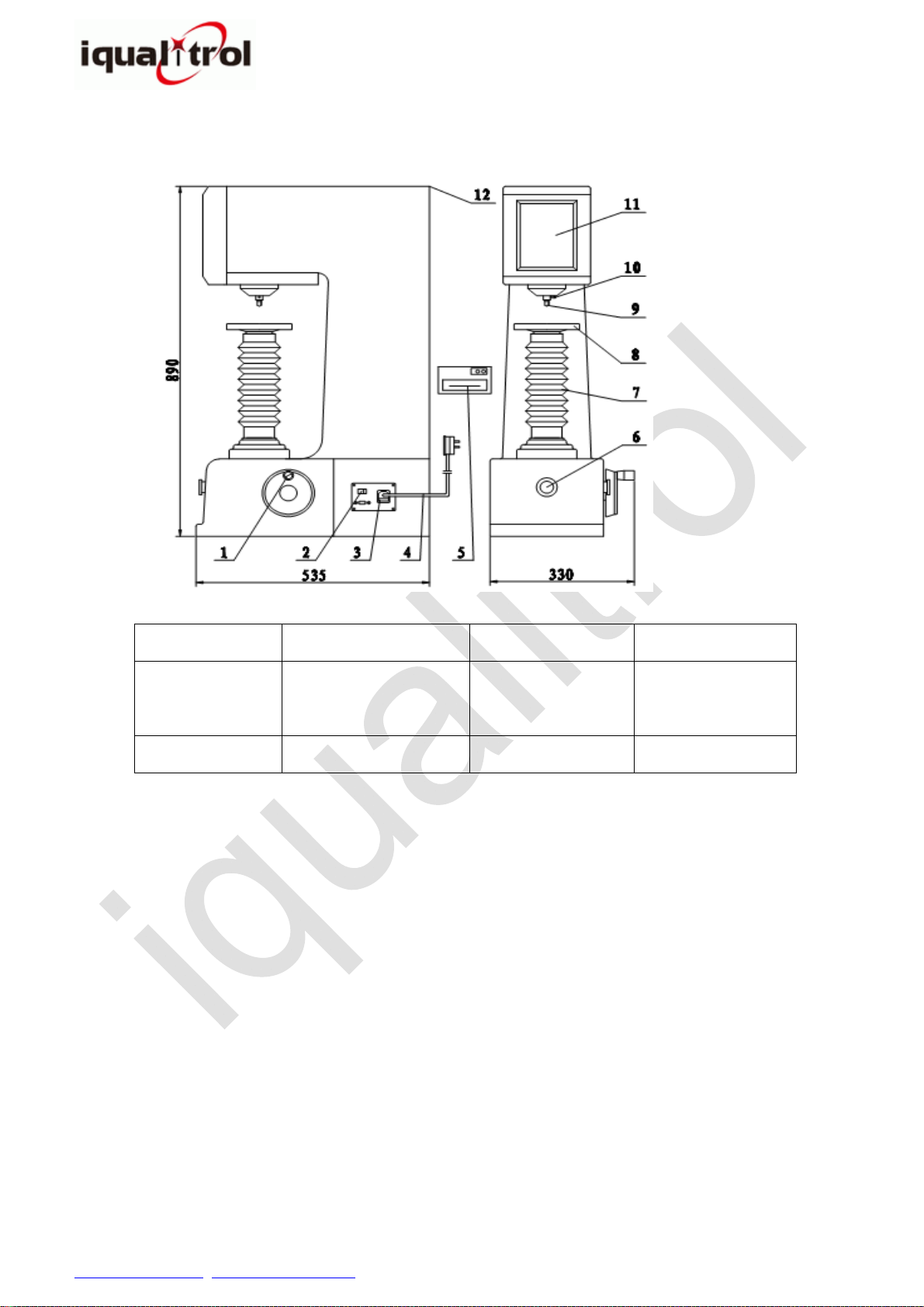

Dimension 535×330×890mm,

Packing Dimension: 820×460×1170mm

Weight Net Weight: 80kg,Gross Weight: 100kg