www.iqualitrol.com, sales@iqualitrol.com 3

ServiceCall:+86‐13711988687

One.Precautions

1. It is advisable to use the single‐phase 3‐pin plug for the electric connection on the present

instrument. The grounding end must be according to the stipulatedrequirementforearth

protecting.

2. Itisnecessarytoreadcarefullytheusageinstructionmanualbeforetheoperationofthepresent

instrument in order to know the operational procedures and the precautionssoastoavoidthe

damagestotheinstrumentandthepersonalsafetycausedbytheincorrectoperation.

3. Duringtheinstallmentandthe preoperational test,the stickingpaper thatprotectsthe indenter

againsttheshockduringthetransportationshouldbetakenoffcarefullybecausetheover‐strength

indoingitwouldaffectthepositionalprecisionoftheindenter.

4. Itisprohibitedtodismountandalternatewithoutpermissionalltheelectriccomponentpartsand

the switches as well as their fixed positions. Those who do such unwarranted actions will be

responsiblefortheirconsequences.

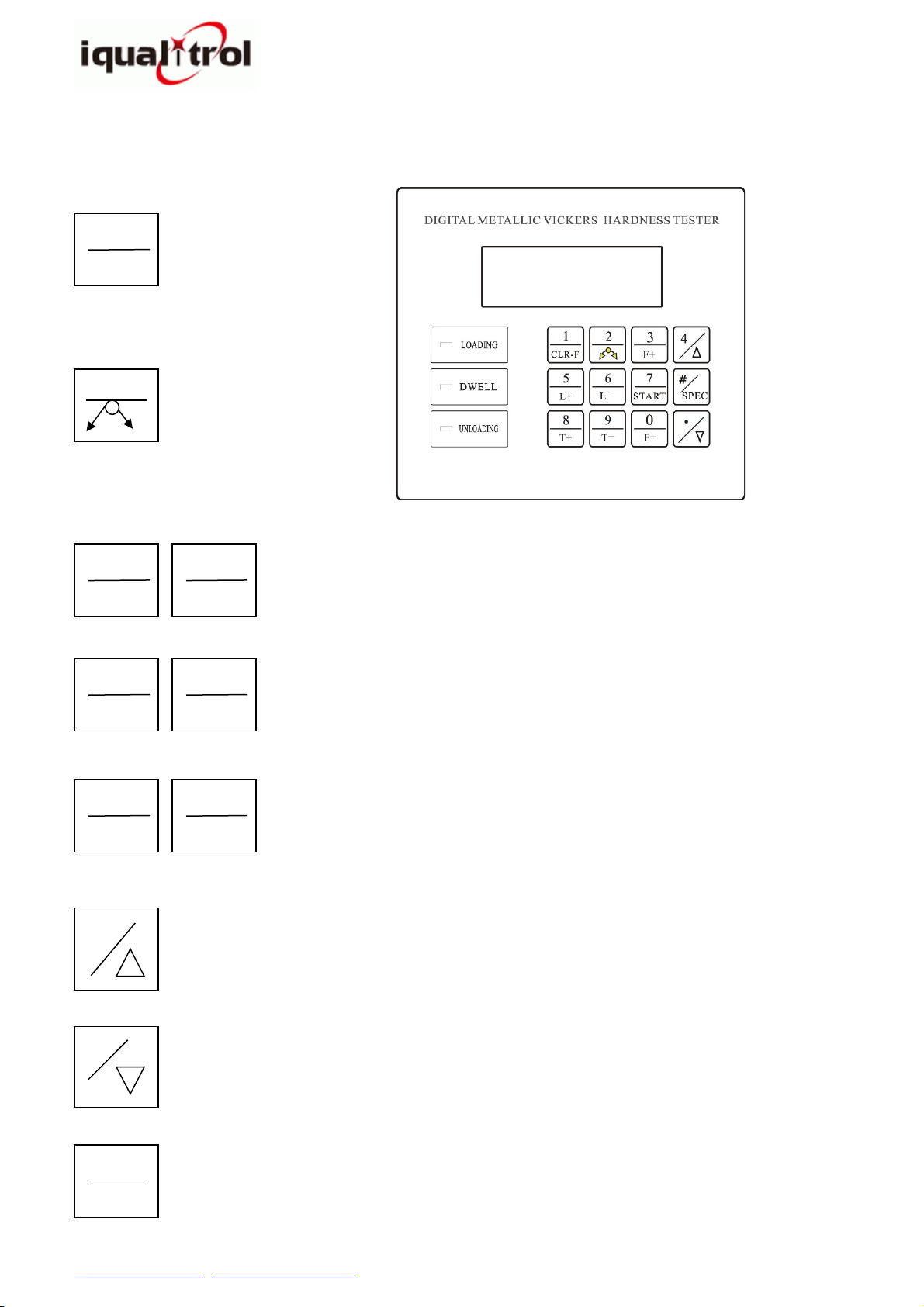

5. During the loading process, press the “START” key immediately in case of emergency, and the

instrumentwillstoploadingautomaticallyandreturntoinitialposition.

6. Duringtheloading,dwellingandunloadingprocess,presstheemergencystopbuttonimmediately

incaseofemergency,andtheinstrumentwillstoptestingautomaticallyandreturntoinitialpositio

n.

7. Our company tries to improve the quality of the hardness testers and renew their structure

continuously. In case the contents in the usage instruction manual are a bit different with the

actualstructureoftheinstrument,itishopedandapologizedforthefactthatthefurthernotice

willnotbegiven.

Two.BriefIntroduction

1. TheVickersHardnessTesterisanewandhigh‐techproductcombiningtheoptical,mechanicaland

electronic techniques, with a good aesthetic aspect, operational functions and reliability, and

henceitisanidealinstrumentforthetestingofVickershardness.

2. The instrument adopts closed‐loop loading control system, it makes the test accuracy improved

andtherepeatabilityandstabilityofthevaluebetter.

3. Withthesoftkeysonpanelboardforinputoperation,itcanpresetthetestingforcedwelltime,

adjustintensityoflightsourceandshowstheindentationlength,hardnessvalue,dwelltimeand

thetestnumber.Ithasthefunctionofautomaticshiftingbetweentheindenterandobjective.

4. Accordingtotheparticularrequirementsoftheclient,thetester can be equipped with CCD

indentation automatically measuring device. The instrument is suitable for the testing Vickers

hardness value of the micro and thin pieces, permeated and coated plane surface, the crisp

materialssuchastheagate,glassanditis,therefore,anidealhardnessmeasuringinstrumentfor

the scientific research institutes, the universities, the industrial production units and the

metrologicalinstitutes.