2 di 18

DISCLAIMER

The Power Slide Control is intended for use on a closed circuit onl . The Power Slide Control

is not road homologated. The Power Slide Control is not a safet component. Sliding losses

mean possible driver crash; the Power Slide Control aim is onl to support the driver in this

phase, reducing or deleting, if possible, the sliding conditions. The Power Slide Control

does not guarantee the possibilit of sliding off and driver’s crash. It is not guaranteed that

the Power Slide Control avoids crash of the bike with possible damage to the bike, driver

or third parts.

The Power Slide Control allows to user several settings both during installation and use. A

wrong setting could affect, partiall or full , the s stem effectiveness. Even the wrong

fitment of the front and rear sensors could affect the s stem performances. Take particular

care to chain adjustment operation that could misalign the rear sensor if not properl

bracket.

The use of this product is at the sole discretion of the user. The manufacturer of this

product is not liable for an kind of damage or injur caused to the operator, vehicle, or to

third parts.

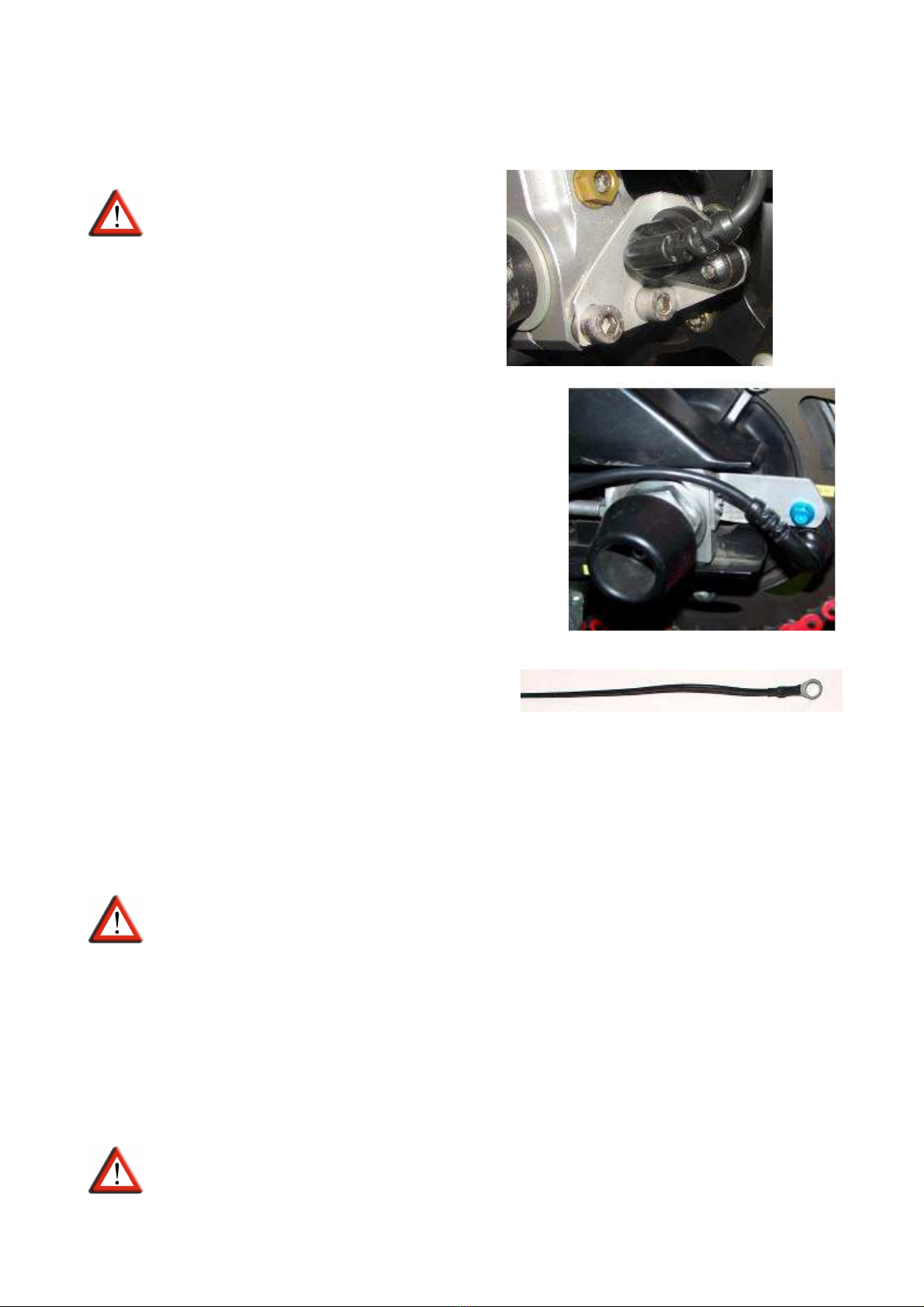

The Power Slide Control installation must be done according to following instructions. It’s

strongl suggested to test the Power Slide Control and the bike after the installation.

WARNING:

Each s stem modification, both hardware and software and

harness or single components, could affect the s stem functionalit with of

damage or injur caused to the operator, vehicle, or to third parts and delete the

product warrant .

Installation must be done carefull following these instructions. Si consiglia di testare il

Power Slide Control. It’s strongl recommended to test the product and the bike after the

installation.

WARNING

: Installation is a ver critical operation for s stem effectiveness. Be

sure that it is done b clever and specialized personnel.

WARNING

: Even in the case that the s stem is been installed and set b

specialized personnel, the end user must follow all tests according to the

procedure describe in the following paragraph 6th (Pre use tests).

The PSC is a race use onl product so the warrant on its parts and components is onl

ONE ear from date of purchase.

This manual is issued on March. 5

th

2010 in Rev. 1.1. It’s end user responsibilit periodicall

visit the website www.irccomponents.com in order to check new releases of manual and

software. The eventual re-programming will be done free of charge except the shipment

cost.