IWF 1131 8

Fault finding

Ref. No. 31-8931-0201-04/0103

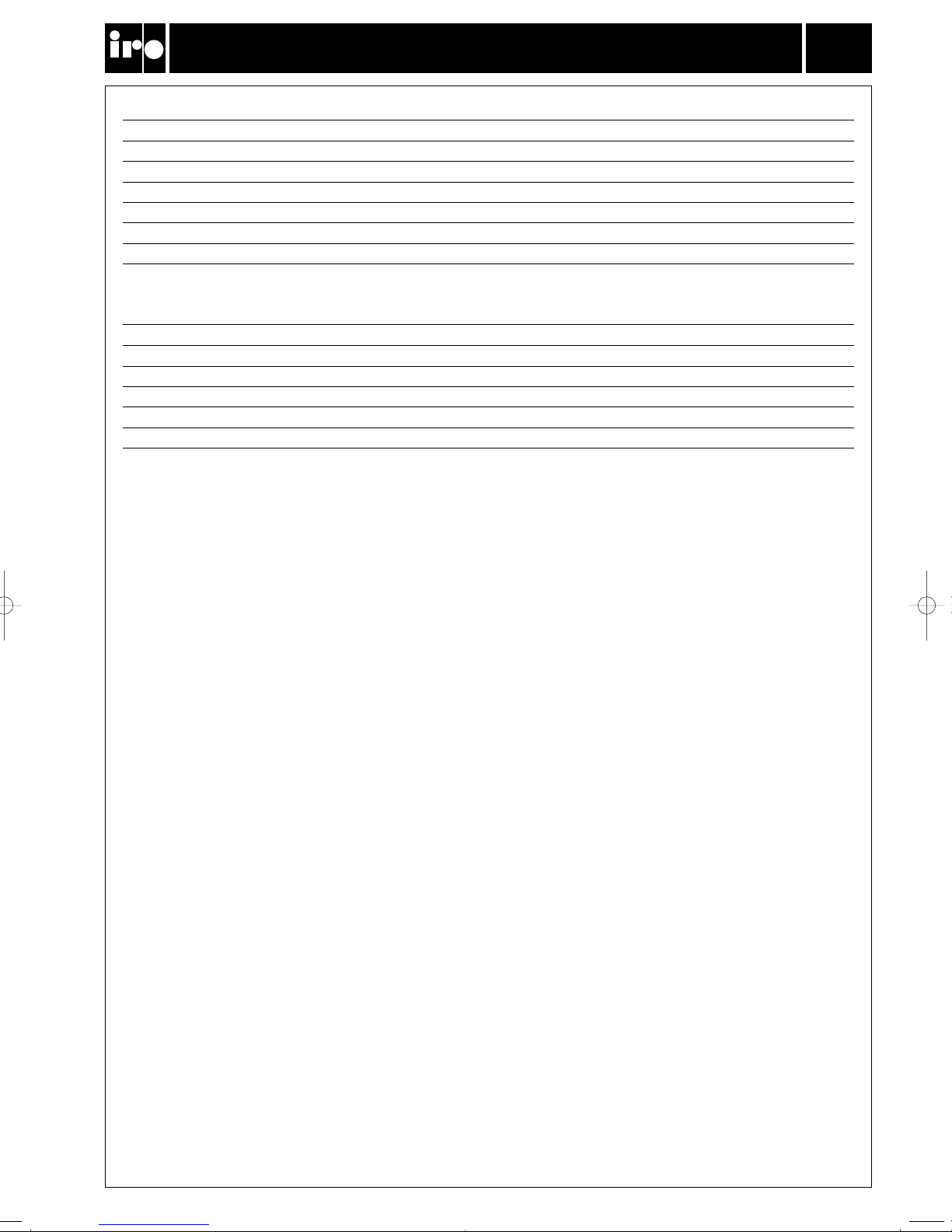

Fault Check in the following order

The unit will not start 1 20 3 2 4 5 12 6

The unit will not stop 3 20 7 6 5 18

The yarn store runs out (without input sensor) 1 20 19 3 2 8 5

The yarn store runs out (with input sensor) 1 20 19 3 2 5 9

The magnet pin does not respond to the yarn release switch 1 10 5 14 12

Incorrect pick lengths 1 7 11 3 17 10 5

Excessive yarn store / overfilling 1 20 3 4 6 5 18

Stop reasons on loom display Check in the following order

Basic settings not received 4 5 12

Communication error 4 13 5 12

Yarn store not full 15

Overheated prewinder 2 16 5 12

Incorrect motor voltage 16 14 12 5

Incorrect magnet voltage 5 14 16 12

WARNING

ALWAYS TURN OFF THE MAIN SWITCH BEFORE DISCONNECTING OR CONNECTING

THE FEEDER OR ANY OF THE CIRCUIT BOARDS. ALL WORK ON ELECTRICAL COMPONENTS

SHALL BE CARRIED OUT BY A QUALIFIED ELECTRICIAN.

1. Check weaving machine display

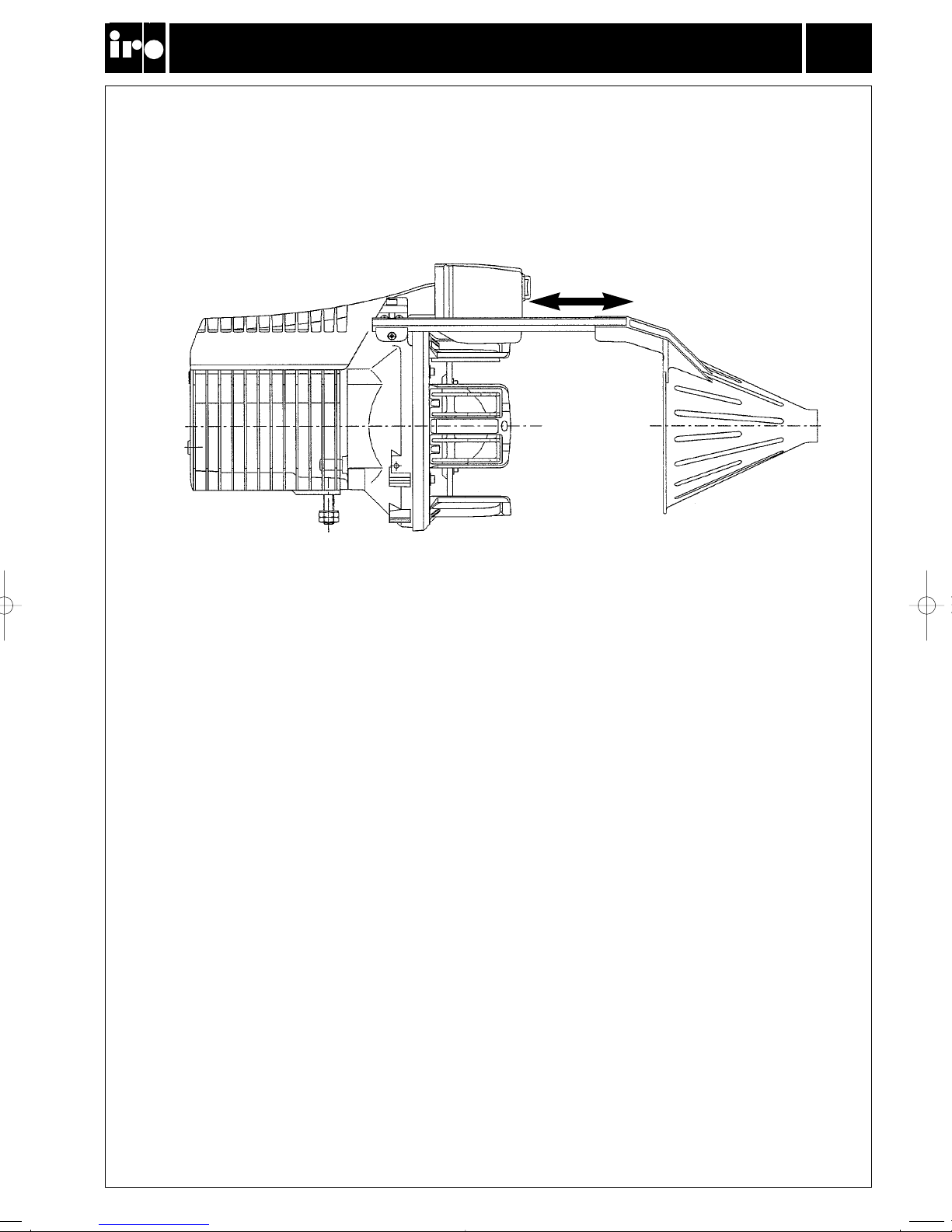

2. Check that the winding disc runs free

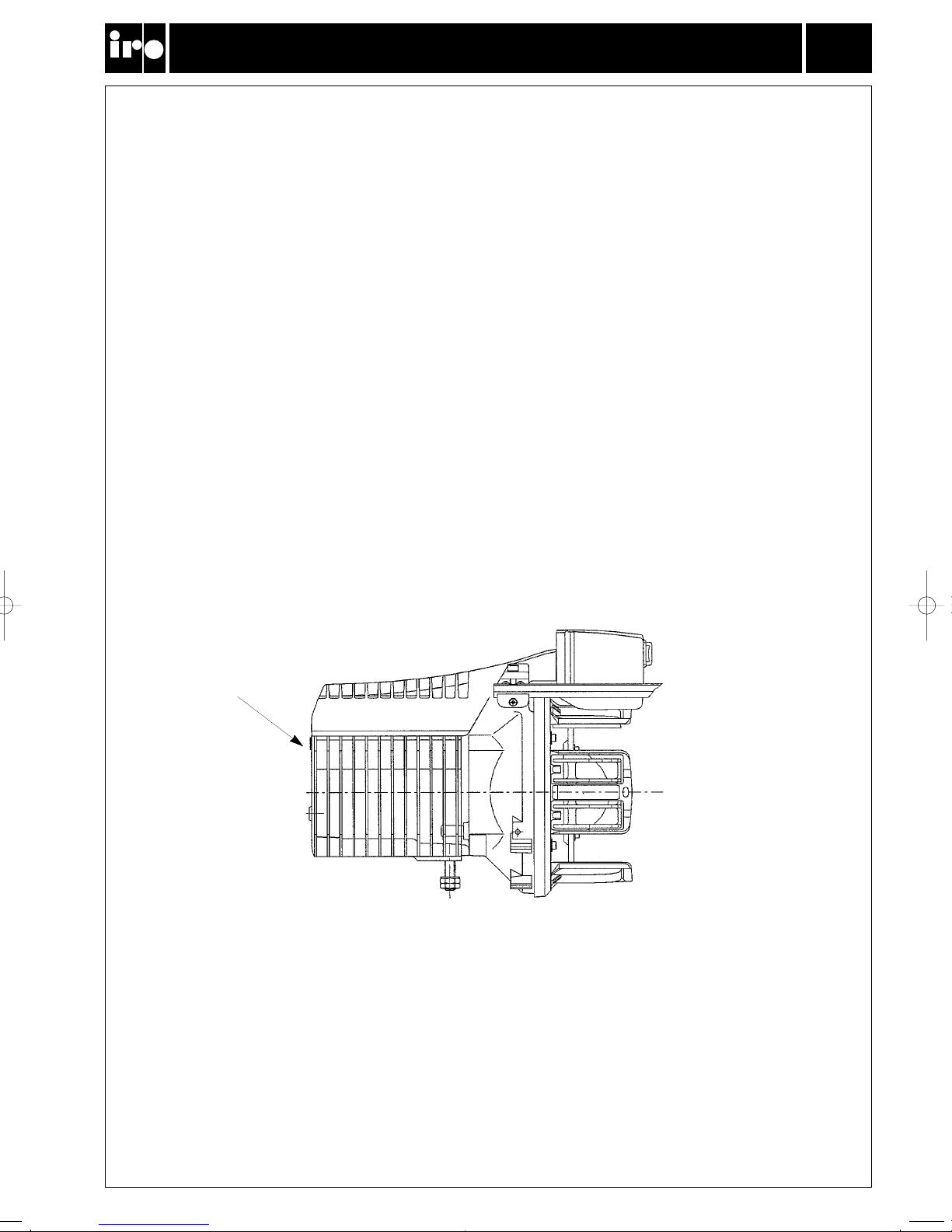

3. Clean sensors and spoolbody

4. Check cable connections

5. Replace motor circuit board

6. Replace yarn store sensor

7. Check distance between magnet support and magnet finger

8. Strong yarn trapped at input side

9. Check that the weaving machine stops when the yarn breaks

10. Replace the stopper magnet

11. Check pick length setting

12. Replace interface/supply circuit board

13. Check mains supply

14. Check fuses on the interface/supply circuit board

15. Fill up the yarn store before starting the weaving machine

16. Check voltage level

17. Replace winding sensor

18. Replace wind-on sensor

19. Check whether yarn store is sufficient.

20. Reset the reserve sensor by switching off the feeder, remove the yarn store and switch on the feeder

31-8931-0201-04/0103-GB 01-01-22 12.40 Sidan 9