8

GB

Concentrate on what you are doing. Take a

sensible attitude to your work. Never use the tool

when you are tired.

Never use a tool with a switch that cannot be

turned on and off.

Caution! The use of plug-in tools and

accessories other than those intended may put

you at risk of injury.

Always pull the plug out of the power socket

before adjusting or servicing the machine.

Give these safety regulations to all persons who

work on the machine.

Do not use this saw to cut fire wood.

Do not use this saw to cross-cut roundwood.

Caution! Hands and fingers may be injured on

the rotating saw blade.

The machine is equipped with a safety circuit-

breaker (11) to prevent it starting up again after a

voltage drop.

Before you use the machine for the first time,

check that the voltage marked on the rating plate

is the same as your mains voltage.

If you need to use an extension cable, make sure

its conductor cross-section is big enough for the

saw’s power consumption. Minimum cross-

section: 1 mm2.

If you use a cable reel, the complete cable has to

be pulled off the reel.

Do not carry the tool by its cable.

Check the power cable (9). Never use a faulty or

damaged power cable.

Do not use the cable to remove the plug from the

socket-outlet. Protect the cable from heat, oil and

sharp edges.

Do not leave the saw in the rain and never use it

in damp or wet conditions.

Provide good lighting.

Non-slip shoes are recommended when working

outdoors.

Do not saw near flammable liquids or gases.

Wear suitable work clothes! Loose garments or

jewelry may become caught up in the rotating

saw blade.

Wear a hair net if you have long hair.

Avoid abnormal working postures.

Operators have to be at least 18 years of age.

Trainees of at least 16 years of age are allowed

to use the machine under supervision.

An untidy work area invites accidents.

Do not allow other persons, especially children,

to touch the tool or cable. Keep them out of your

work area.

Keep children away from the machine when it is

connected to the power supply.

Keep your workplace clean of wood scrap and

any unnecessary objects.

Persons working on the machine should not be

distracted.

Note the direction of rotation of the motor and

saw blade.

After you have switched off the motor, never

slow down the saw blade (4) by applying

pressure to its side.

Fit only blades (4) which are well sharpened and

have no cracks or deformations.

Use only circular saw blades (4) made of high-

alloy high-speed steel (HSS).

Never dismantle the machine’s safety devices (2,

5) or put them out of operation.

The machine is to be operated only with tools

which conform with prEN 847-1: 1966.

Faulty saw blades (4) have to be replaced

immediately.

Never use saw blades which do not comply with

the data specified in this manual.

It is imperative to make sure that all devices (2,

15) which cover the saw blade are in good

working order.

Caution! It is prohibited to use this saw to make

plunge cuts.

Damaged or faulty safety devices have to be

replaced immediately.

The splitter (5) is an important safety device. Not

only does it guide the workpiece, it also prevents

the kerf closing behind the blade so that there is

no kickback from the workpiece. Note the

thickness of the splitter. The splitter should never

be thinner than the saw blade body or thicker

than the width of its kerf.

The guard hood (2) has to be lowered over the

workpiece for each cut.

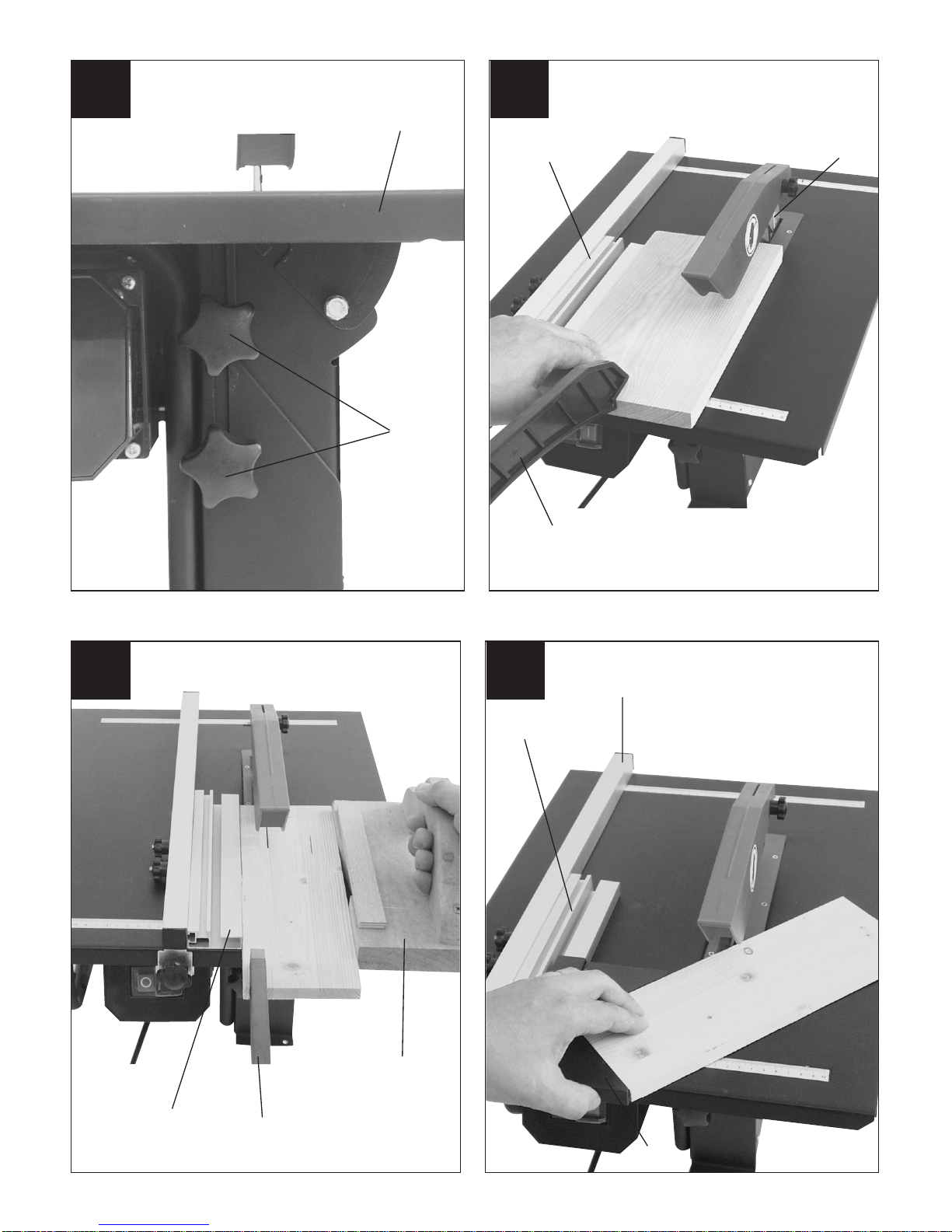

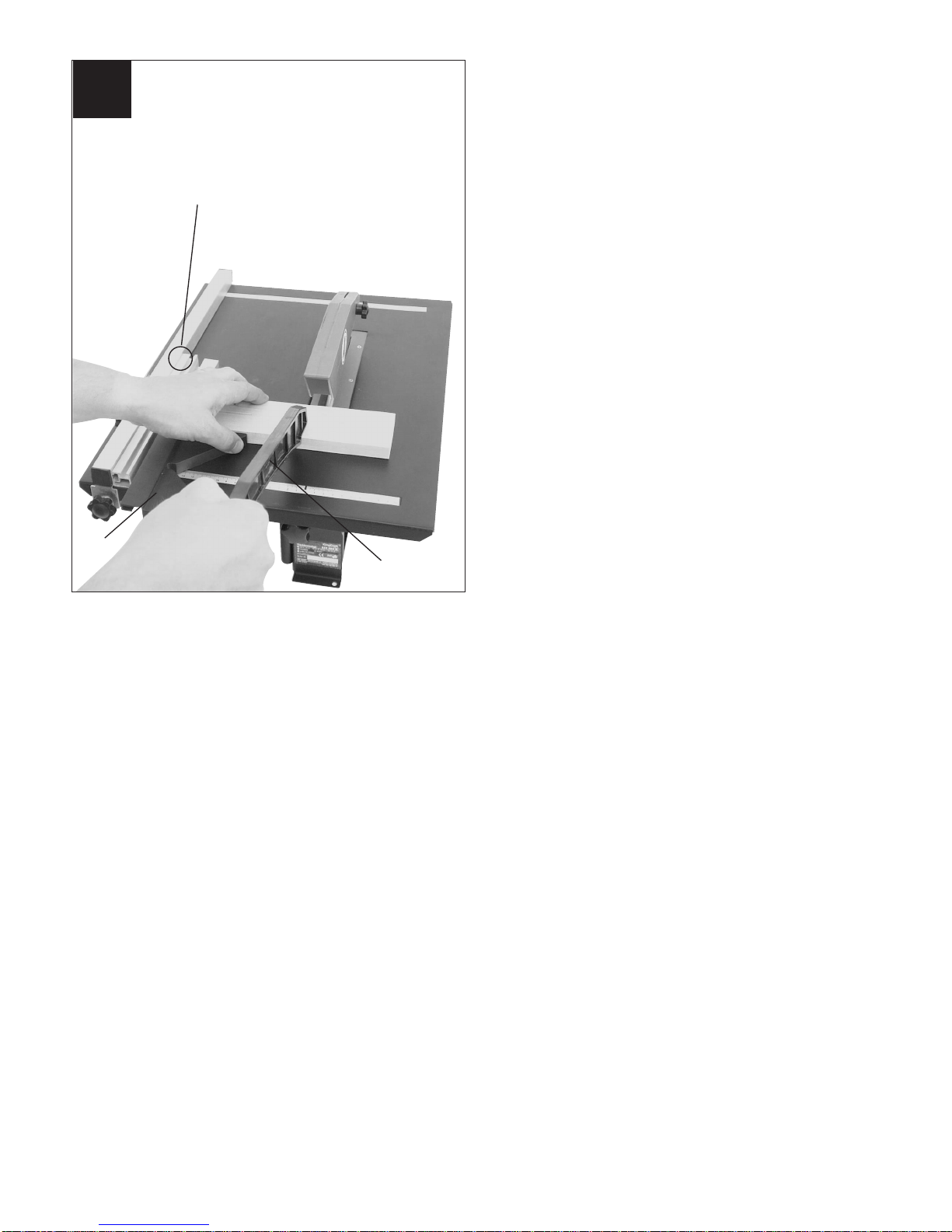

Be sure to use a push stick (3) when slitting

narrow workpieces (smaller than 120 mm in

width).

Never cut workpieces which are too small to hold

securely in your hand.

It is imperative for the parallel stop to be clamped

on the right-hand side of the blade whenever you

cut narrow workpieces to size.

Always stand to the side of the saw blade when

working with the saw.

Never load the machine so much that it cuts out.

Always press the workpiece firmly against the

saw table (1).

Make sure that off-cuts do not catch on the saw

blade crown. Risk of catapulting!

All guards and safety devices have to be refitted

immediately after completion of any repairs or

maintenance.