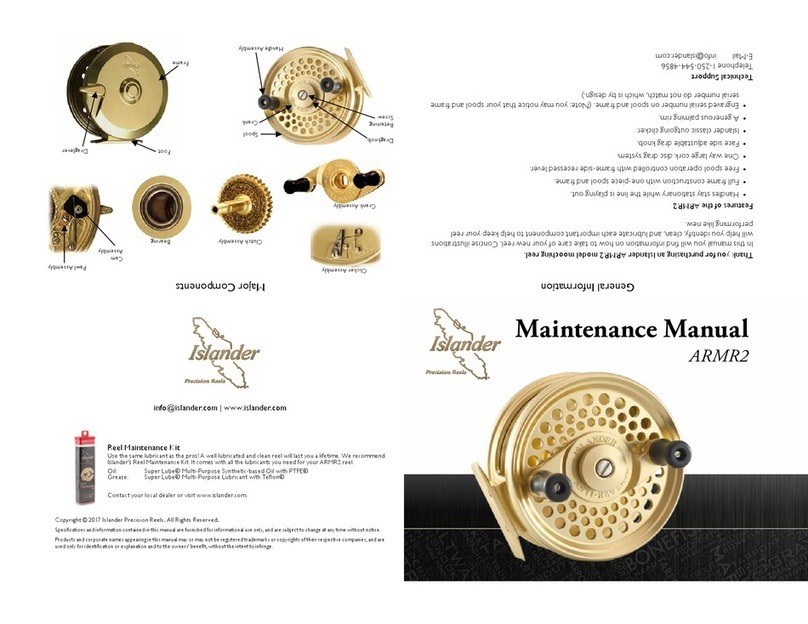

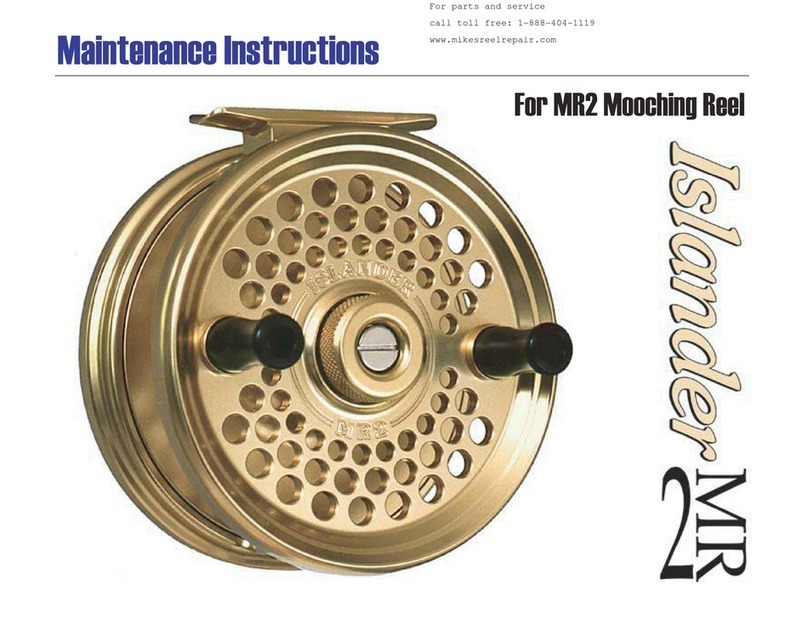

Spool

7. Remove all the old grease from the gear (5). You may

need to use a small, soft brush.

8. Clean the bearings (6 — there is another identical

bearing opposite to the one shown); use a soft cloth to

remove any debris that may have accumulated.

9. Clean inside the spool cavity with a soft cloth to

remove any contaminant which may have collected.

10. Oil and grease all of the indicated locations.

Remember to oil both the front and back bearings.

11. The o-ring under the spindle screw should be cleaned of any build up and then oiled (Figure 7).

12. The handle assembly (Figure 8) does not have to be lubricated. Simply remove the screw holding the

handle with a at bladed screw driver and clean thoroughly by wiping down the base with a soft cloth

and running a cotton swab through the handle.

Figure 6 - Spool

5) Gear

(Grease teeth)

6) Bearing

(Oil front &

back bearings)

Figure 7 -

Spindle Screw Figure 8 - Handle Assembly

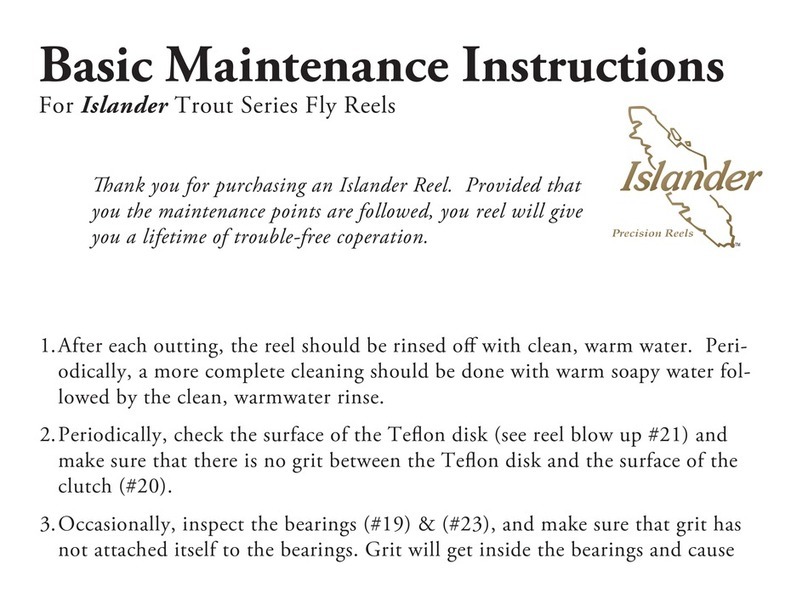

Your reel comes lubricated from the factory. This level of maintenance should be

carried out once every 3-4 shing trips to maintain optimum per formance.

After use in saltwater, it is important to rinse the reel with warm water.

While the reel is saltwater safe, the quick rinse will help your reel

perform better in the long run. Avoid immersing the spool in water if

there is backing/line present — moisture will be retained by the line.

4. Clean the inside of the frame with a soft cloth to remove

any contaminants which may have collected.

5. Oil and grease all of the indicated locations.

6. After lubrication, work the clicker button (4) back and

forth a few times to work the lubrication through the

button and clicker assemblies.

Figure 4 - Frame

3) Spindle

(Oil)

2) Clicker

(Oil &

Grease)

1) Clicker

Spring

4) Clicker Button

(Oil underneath)

Frame

1. Disassemble your reel as shown above.

2. Clean the Spindle (3) using a soft cloth to remove any

old buildup that may have accumulated.

3. Clean around the Clicker (2) and Spring (3). You may

have to use a small, soft brush to remove the old oil,

grease and grit from this location.

Figure 5 -

Frame

Cleaning and Lubricating Your Reel

Tuning

Troubleshooting

1. If you nd that your handles are still, remove the handles as show below and clean

them. Most poor turning handles are caused by a collection of grit that accumulates

between the handle and the handle base. (See step 12 bellow.)

2. If you nd that your clicker button does not engage or disengage properly, clean and

oil around the clicker and button assemblies as shown below.

It is possible to tune the intensity of the reel’s click, to a

certain extent. For these adjustments, you will need to

disassemble your reel.

1. If you nd that your reel is too quiet when

the click-drag is engaged, push the clicker

spring (1) in the direction indicated by (A).

2. If you nd that your reel is too loud when

the click-drag in engaged, push the clicker

spring (1) in the direction indicated by (B).

1) Clicker Spring

A) For a louder click

B) For a softer click

Figure 3

How To Disassemble Your Reel

1. Remove the spindle screw (2) by turning it

counterclockwise, using a snug-tting screw

driver.

2. Once the screw is removed, you may notice

that there is a captive rubber O-ring on the

underside of the spindle screw (2). There is

no need to remove this O-ring, and it will

not fall out on its own.

3. Grasp the outside of the frame (3) with one

hand and the spool (1) with the other, and

start to pull the reel apart gently in a straight

line manner. Nothing should be forced during

disassembly or reassembly.

At this point, there should be 3 free assemblies:

Spindle Screw (2), Spool (1), and Frame(3).

Reassembly Notes

• Disengage the clicker, as illustrated in Figure 2.

• Do not overtighten the spindle screw (2). Tighten the

screw just until it meets resistance.

(3) Frame

Figure 1

(2) Spindle Screw (1) Spool

4) Push back

and down to

disengage.

5) Push up

to engage.

Figure 2 - Clicker Button