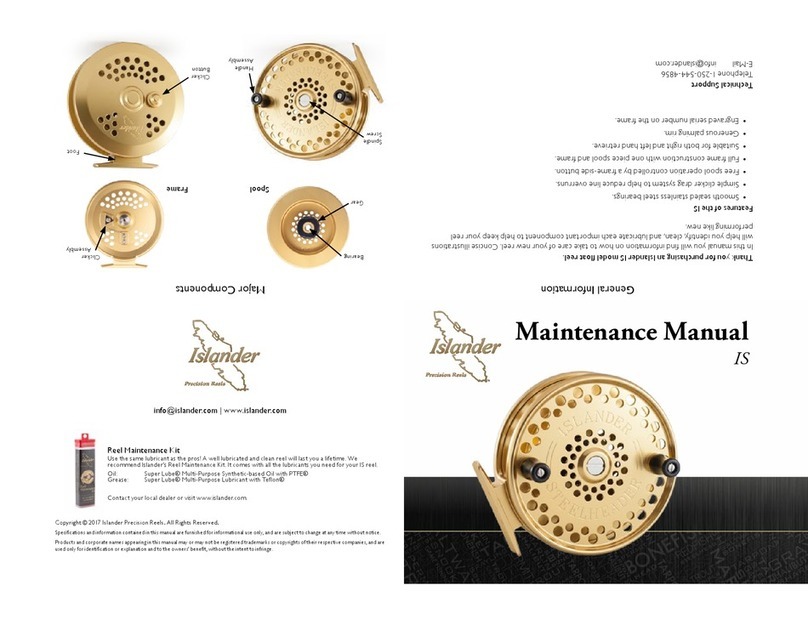

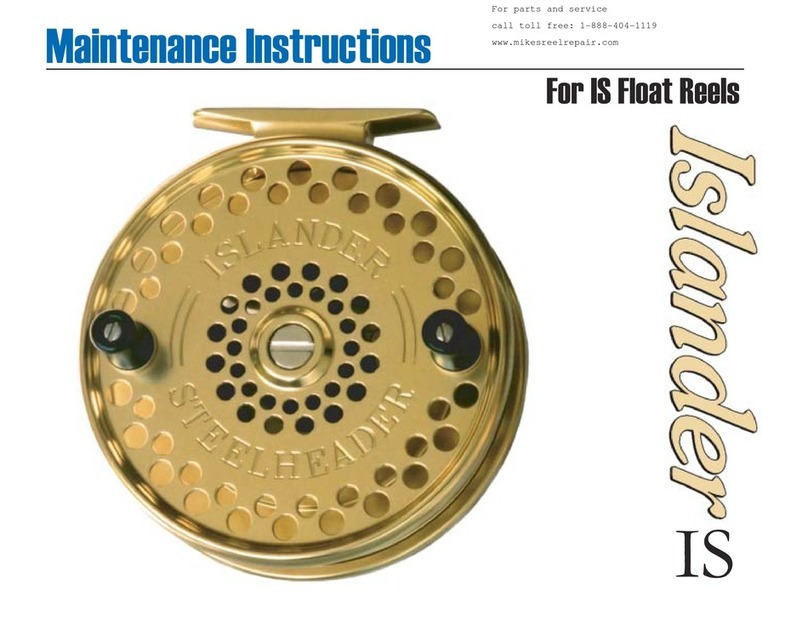

How To Disassemble Your Reel

1. Remove the spindle screw by turning

it counter-clockwise with a at bladed

screw driver.

2. Remove the dragknob by hand, turning

it counter-clockwise untill you can

remove it.

Underneath the dragknob there will be

a stainless steel washer. It will either be

stuck to the bottom of the dragknob or

to the top of the dragspring.

3. Grasp the outside of the frame with one

hand and the spool with the other, and

pull the frame and spool apar t.

At this point there should be 6 free

assemblies: Retaining Screw, Dragknob,

Dragknob Washer, Dragspring, Spool,

and Frame.

Reassembly is the opposite of disassembly. When you are reinstalling the

drag knob, make sure the stainless steel washer is under the drag knob

and not under the dragspring.

(B) Dragknob Figure 1

(A) Retaining Screw

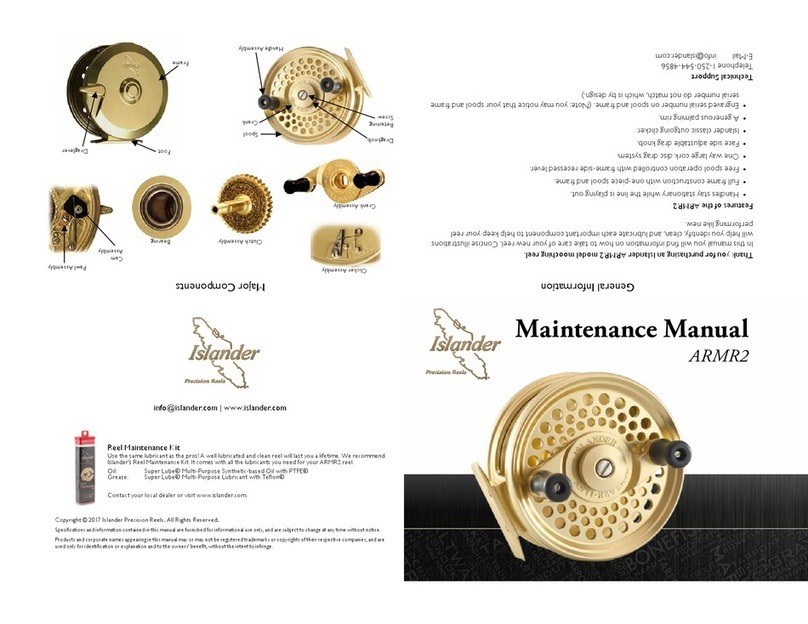

1) Clicker

A) For a louder

outgoing click

Figure 4 2) Clicker Spring

B) For a softer

outgoing click

Figure 2

Left-Hand Retrieve

Figure 3

Right-Hand Retrieve

Tuning

It’s possible to tune the outgoing click (somewhat). For these

adjustments, you will need to disassemble your reel.

1. To make the outgoing click louder, push the clicker

spring in the direction shown by [A], Figure 4.

Push the spring until the clicker [1] is pointing

directly at the bearing on the rear of the spool.

2. To make the outgoing click softer, push the clicker

spring [2] in the direction shown by [B], Figure 4.

Do not push spring more than a few degrees, as

pushing too far will disengage the clicker.

1. Disassemble your reel.

2. Remove the spindle O-Ring (see exploded view).

3. Lift the Clutch Assembly (see exploded view).

4. Arrange the pawl direction as per Fig. 3 or Fig. 4.

5. Replace Clutch Assembly and Spindle O-Ring.

6. Reassemble your reel.

Retrieve Conversion (Right & Left-Hand)

Cleaning and Lubricating Your Reel

1. Frame Assembly and Foot / Reel

Seat - Rinse and dry af ter use.

2. Pawl Assemblies - Remove old oil and

any grit. Apply a drop of oil around

the springs and pawl.

3. Spindle - Remove all the old lubricant

and any grit from the spindle and

apply a small amount of grease to the

base of the spindle.

4. Clutch Surface - Wipe cork surface to

remove excess oil and graphite. Apply

a small amount of oil and powdered

graphite to the cork surface and work

it in with your nger.

5. Clutch Assembly - Remove old grease and any grit from the bearing, inside and out. Apply

a small amount of grease to the bearing. Remove old grease from between the teeth of the

clutch. Apply a small amount of grease between the teeth.

6. Spindle O-Ring - Remove old grease and any grit prior to clutch installation.

This level of cleaning or lubrication should be carried

out once every 3-4 shing trips. Because of saltwater

conditions, it is important that the reel be rinsed off under

a warm water stream after each trip. While the reel is

saltwater safe, the quick rinse will help your reel perform

better in the long run. Avoid immersing the spool in water,

because moisture will be retained by the backing and line.

7. Spool Assembly - Rinse and dry after

use.

8. Front and Rear Spool Bearings - Remove

old grease and grit with a dry cloth. Apply

a small amount of grease to the exposed

bearing shields.

9. Handle Assemblies - If the handles start

to stick, you can remove the handle from

the base by undoing the handle screw and

remove any grit. No lubrication is required.

10. Dragspring and Drag Knob Washer -

Remove old grease and any grit.

11. Drag Knob - Remove old grease and any

grit. Clean center threads using a cotton

swab or a small cloth. Apply a small amount

of grease to the inside threads.

12. Spindle Screw - Remove old grease and

any grit. Apply a very small amount of

grease around the threads.

13. Clicker Assembly - Remove old oil and any

grit. Apply a drop of oil through each hole

on the clicker, around the screw head and

around the clicker spring.

Your reel comes from the factory lubricated.

Periodic lubrication is recommended to maintain

optimum performance.

1. 2. 3.

4.

7. 8.

9.

10.

11.

12.

13.

5.

6.