4

4) The specialists must have read and understood these Operating Instructions and

must follow the instructions it contains. The Operating Instructions provide detailed

information about the converter. If you are unclear on anything in these Operating

Instructions, you must call the ISOIL service department.

5) Repairs may only be performed if a genuine spare parts kit is available and this

repair work is expressly permitted.

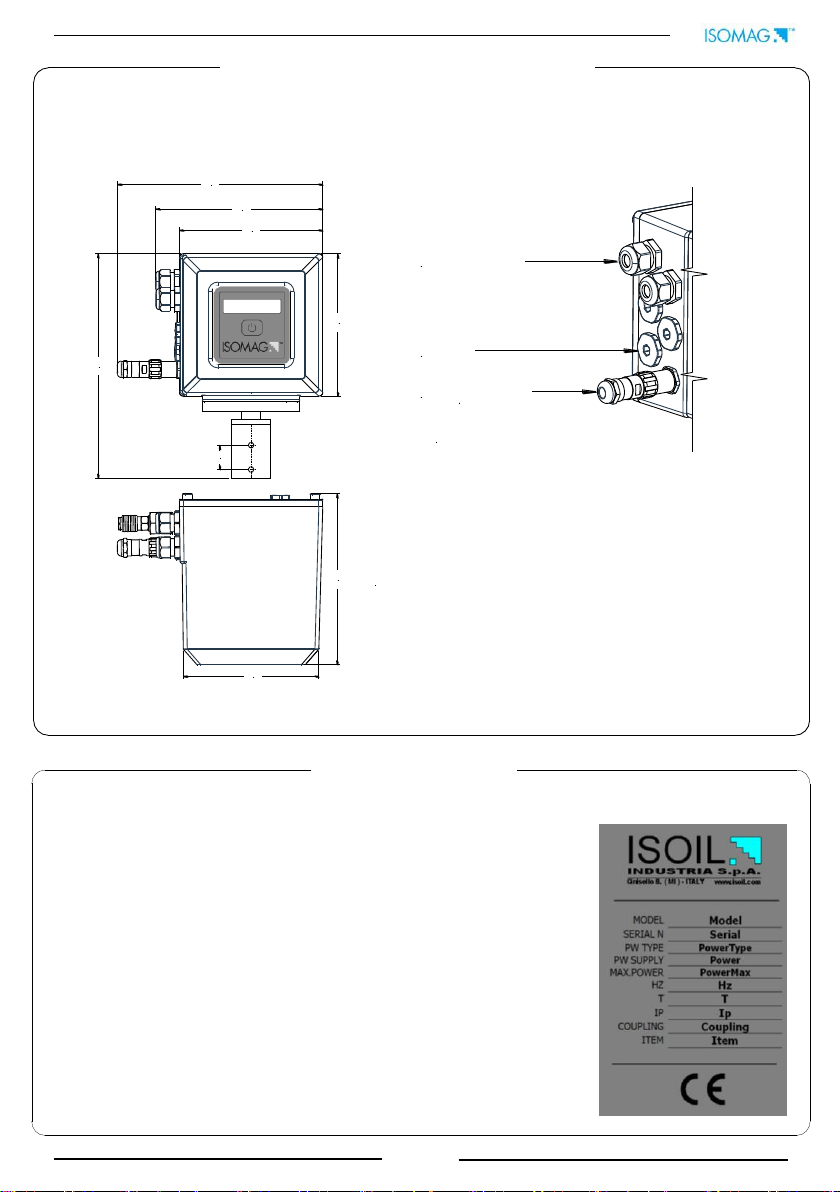

6) The converter should only be installed after have verified technical data provided in

these operating instructions and on the data plate.

7) Specialist must take care during installation and use personal protective equipment

as provided by any related security plan or risk assessment.

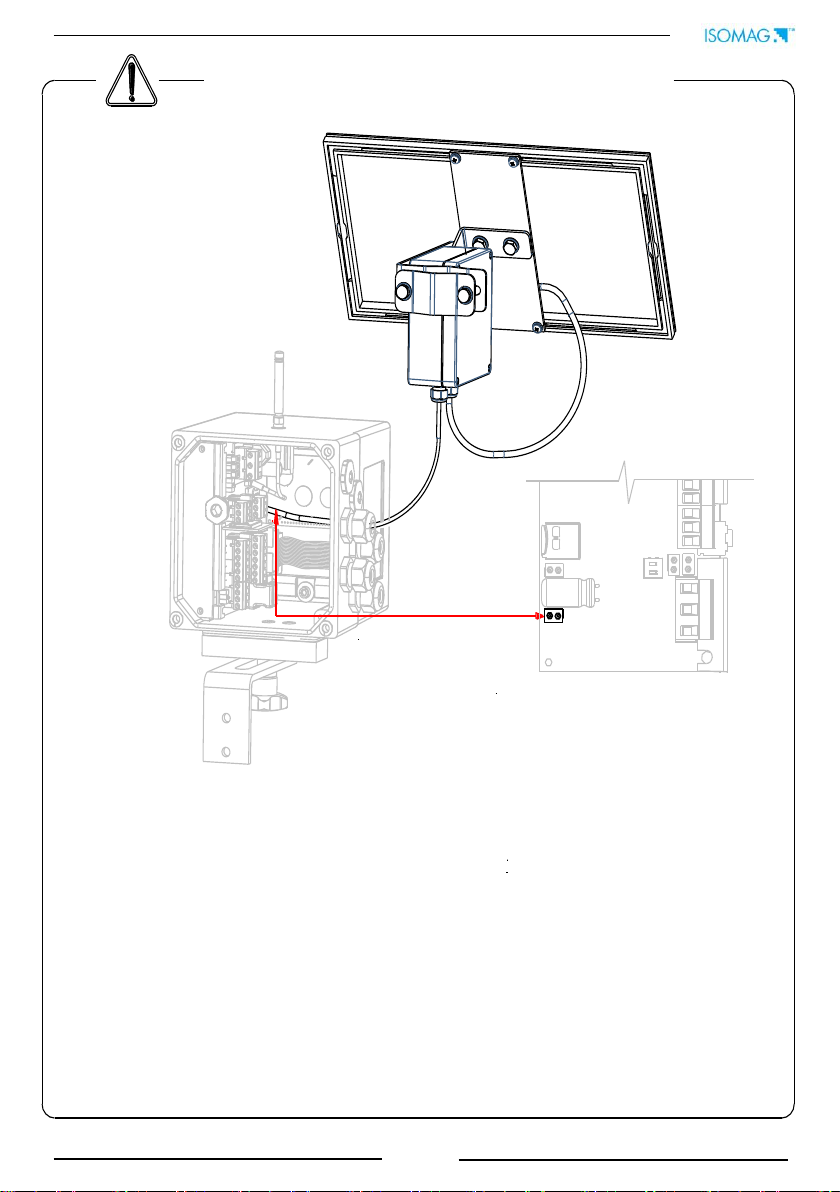

8) Never mount or wire the converter while it is connected to the power supply and

avoid any liquid contact with the instrument’s internal components.

9) Before connecting the power supply check the safety equipment functionality.

10) For the cleaning of the device use only a damp cloth, and for the

maintenance/repairs contact the service center (for details see the last page).

11) To return the product back for service complete and return the meter with form

found in the last pages of these operating instructions.

Before starting up the equipment please verify the following:

Power supply voltage must correspond to that specified on the data plate

Electric connections must be completed as described

Ground (earth) connections must be completed as specified

Verify periodically (every 3-4 months):

The power supply cables integrity, wiring and other connected electrical parts

The converter housing integrity

The suitable tightness of the sealing elements

The front panel integrity (display and keyboard)

The mechanical fixing of the converter to the pipe or wall stand.

SAFETY CONVENTIONS

DANGER

Warning indicates an action or procedure which, if not performed correctly,

can result in injury or a safety hazard. Comply strictly with the instructions

and proceed with care.

WARNING

Caution indicates an action or procedure which, if not performed correctly,

can result in incorrect operation or destruction of the device. Comply

strictly with the instructions.

NOTES

Note indicates an action or procedure which, if not performed correctly,

can have an indirect effect on operation or trigger an unexpected response

on the part of the device.