2

4F1_EN_IS_0_3_5X.doc

INDEX

Introduction_______________________________________________________________________________pag.3

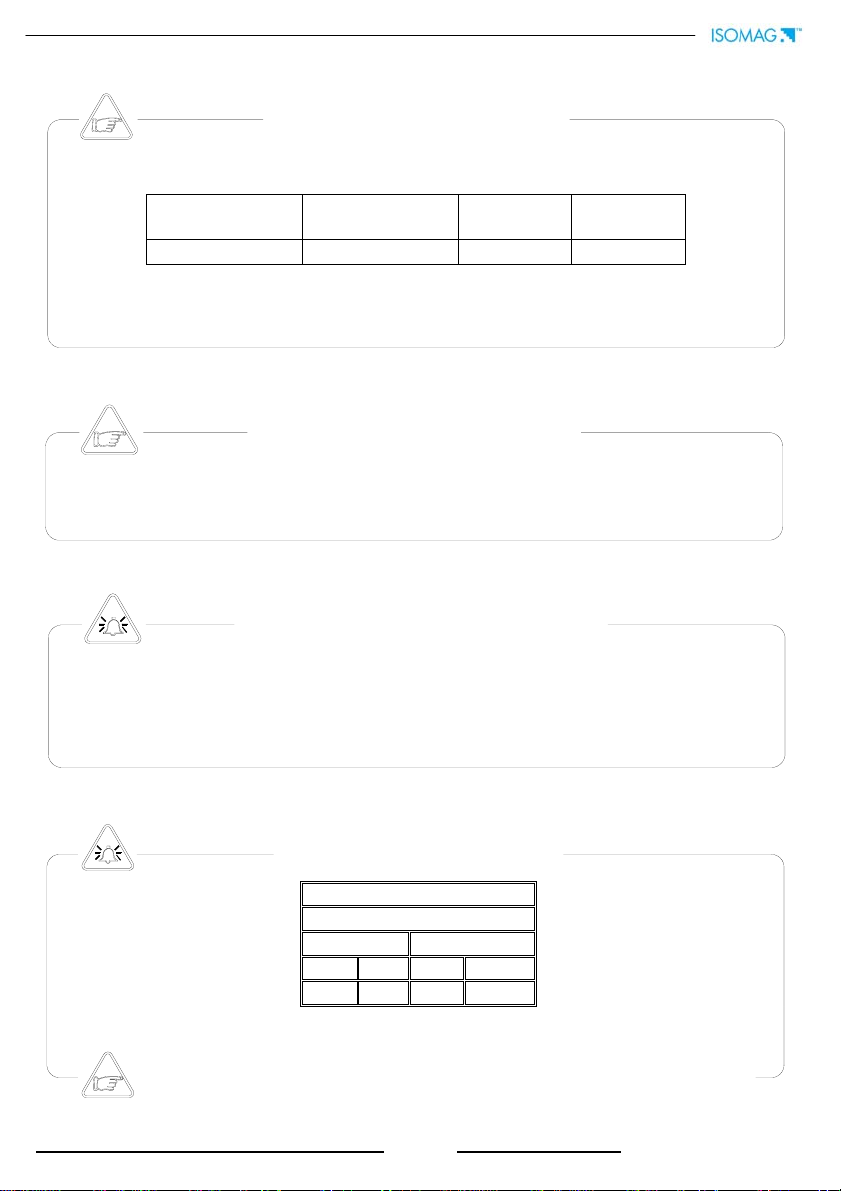

Symbols Used on the manual ________________________________________________________________pag.4

Technical characteristics ____________________________________________________________________pag.5

Electrical characteristics ____________________________________________________________________pag.5

Environmental conditions of use______________________________________________________________pag.5

Operative temperature _____________________________________________________________________pag.5

Overall dimensions ________________________________________________________________________pag.6

Electrical connections_______________________________________________________________________pag.7

Grounding instructions _____________________________________________________________________pag.7

Power supply converter ____________________________________________________________________pag.7

Electrical connections: input-output cables _____________________________________________________pag.8

Electrical connections: sensor cables __________________________________________________________pag.9

Inputs/outputs ___________________________________________________________________________ pag.10

Expansion modules_______________________________________________________________________ pag.11

Digital Input ____________________________________________________________________________ pag.12

Converter visualisation pages ______________________________________________________________ pag.16

Flags interpretation and led ________________________________________________________________ pag.17

Key board ______________________________________________________________________________ pag.18

Access codes____________________________________________________________________________ pag.19

Programming functions____________________________________________________________________ pag.20

How to access to the configuration menu _____________________________________________________ pag.23

Programming functions ____________________________________________________________________ pag.25

Functions description ___________________________________________________________________ pag.25

Batch ____________________________________________________________________________________ pag.31

Enable batch ____________________________________________________________________________ pag.31

Programming batch_______________________________________________________________________ pag.31

Start / stop batch ________________________________________________________________________ pag.32

Important notes _________________________________________________________________________ pag.32

Alarm messages __________________________________________________________________________ pag.33

Causes and actions to be taken _____________________________________________________________ pag.33

Anomalies codes ________________________________________________________________________ pag.33