6 51_EN_IS_1_3_0X.doc

-

+

910

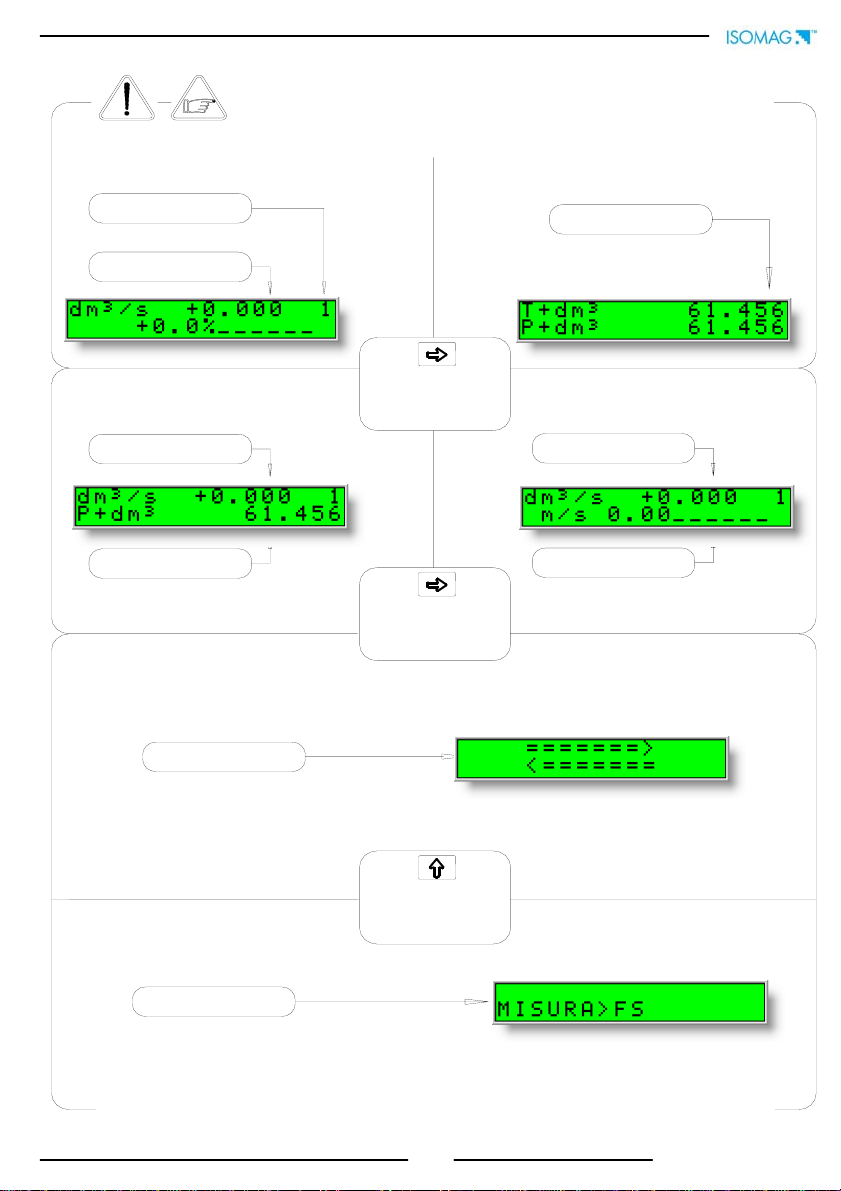

GROUNDING INSTRUCTIONS

For the correct operation of the meter it’s NECESSARY that sensor and liquid are

equipotential, so ALWAYS connect sensor and converter to the ground

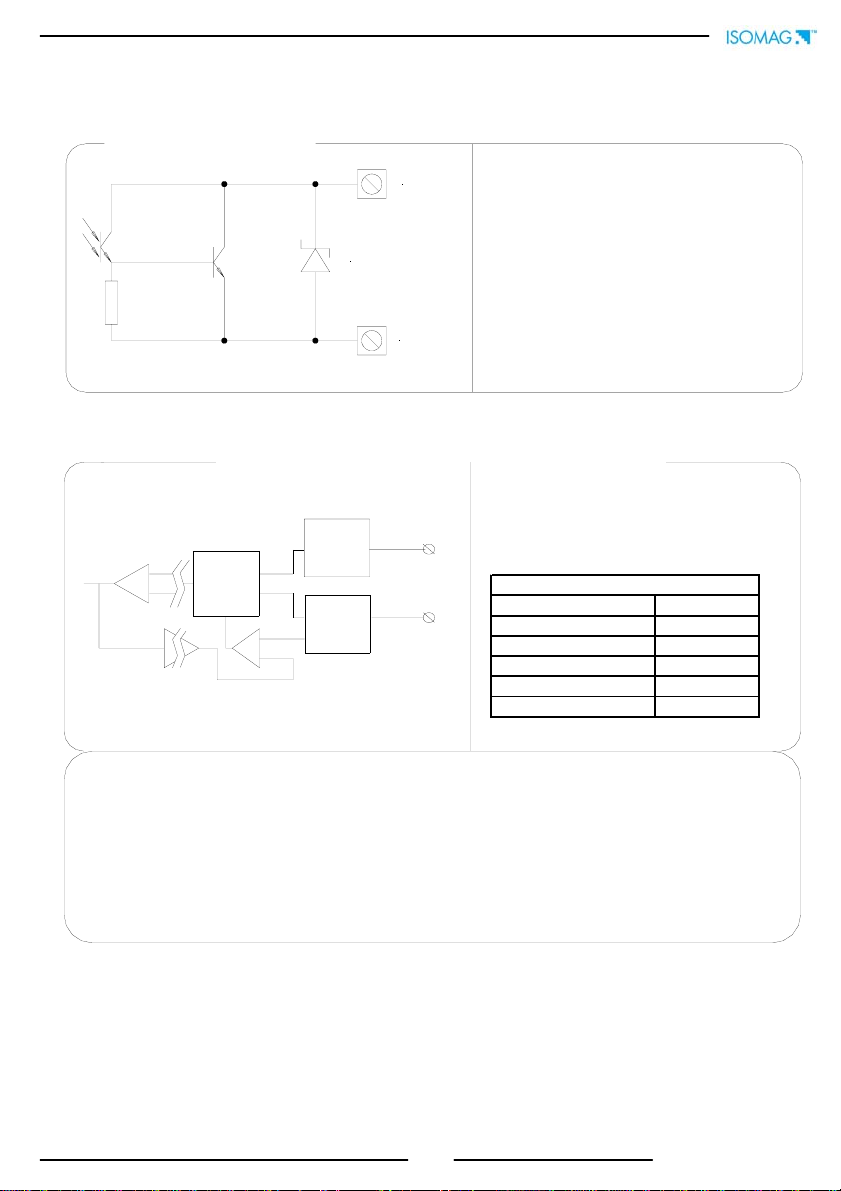

INPUT/OUTPUT ISOLATION

1. Input/output are insulated up to 500V

CONVERTER POWER SUPPLY

Power su

l

Before connecting the power supply, verify that

the mains voltage falls between the limits

indicated on the tag plate

ATTENTION: the converters on dc power

supply line are not protected against the

inversions of polarity.

For the wiring use only approved conductors,

with fireproof properties.

In the proximity of the instrument Provide a

circuit breaker that must be easily accessible

from the operator and clearly identified.

NOTE: characteristics of meter’s power supply, see

page 4