2

Introduction_________________________________________________3

Safety informations ___________________________________________3

Safety conventions___________________________________________________4

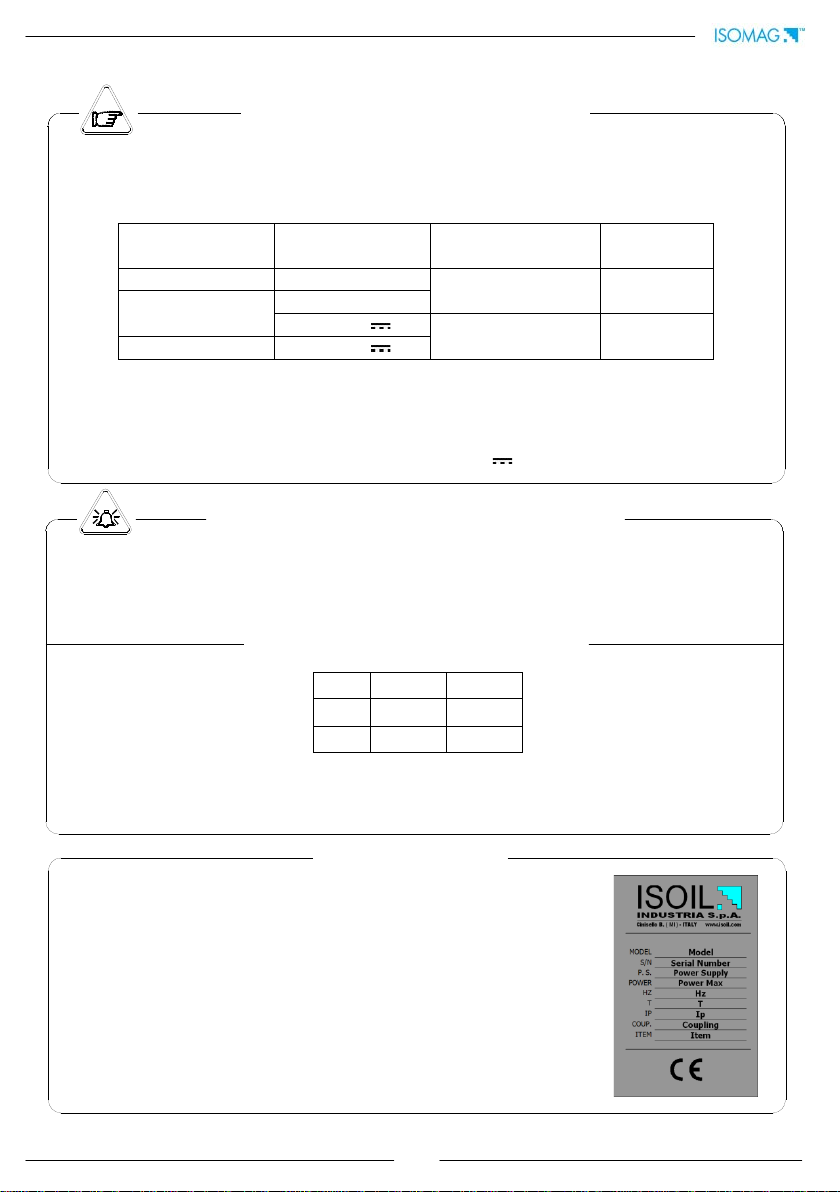

Technical characteristics _______________________________________5

Electric characteristics ________________________________________________5

Environmental use conditions __________________________________________5

Ambient temperature_________________________________________________5

Data plate__________________________________________________________5

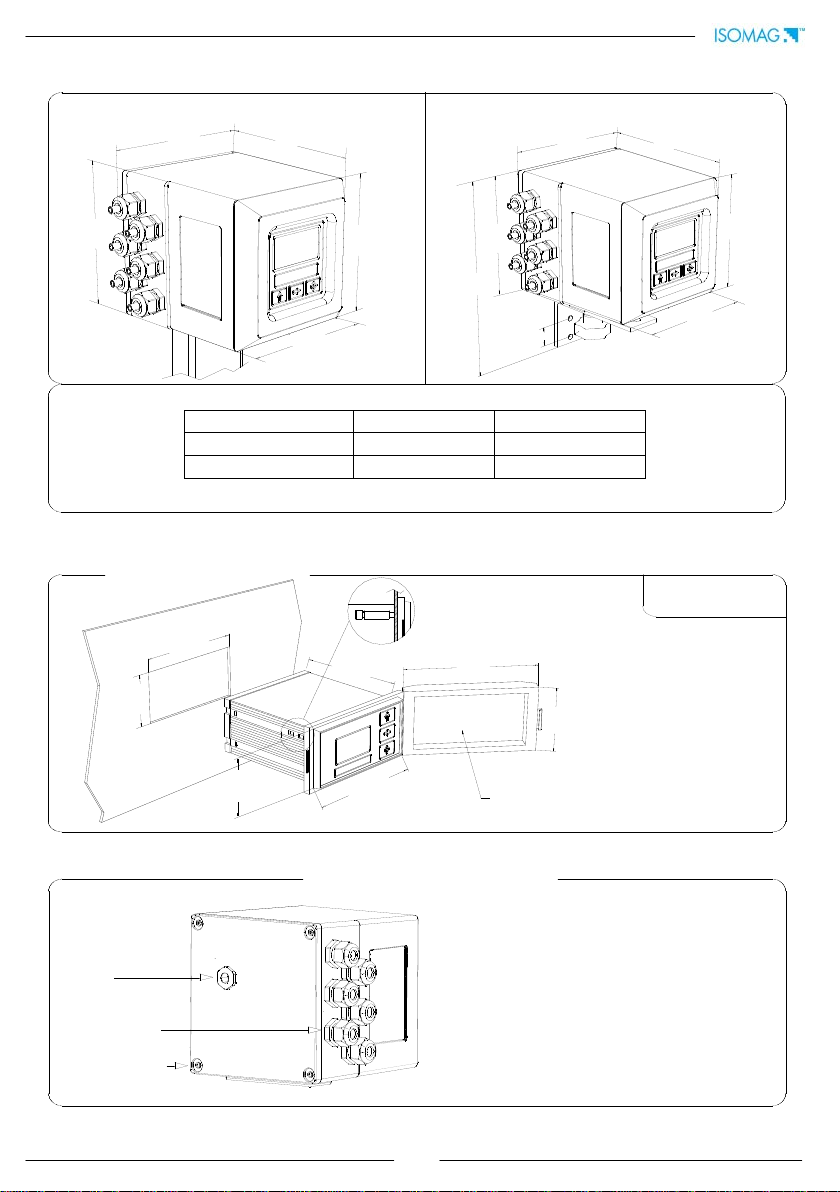

Overall dimensions___________________________________________________6

Electrical connections _________________________________________7

Grounding instructions________________________________________________7

Converter power supply_______________________________________________7

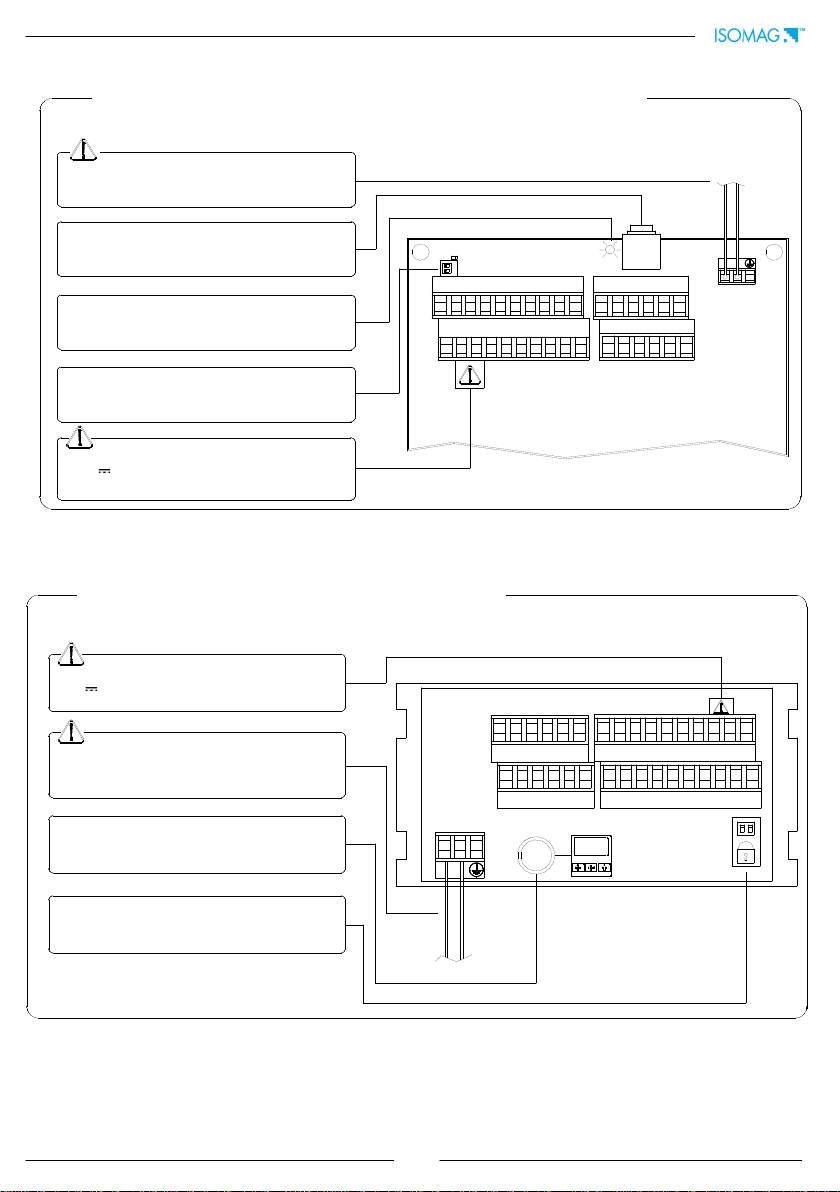

Compact/separate version M1 terminal block ______________________________8

Panel version M1 terminal block ________________________________________8

Converter to sensor electrical connections ________________________________9

Optional modules____________________________________________10

Inputs/outputs _____________________________________________12

Digital input _______________________________________________________12

Input operation stage (generic functions)________________________________13

Operation stage on input 1 or 2 (batch function) __________________________ 14

Operation stage on input 1 and 2 (batch function)_________________________ 15

Output wirings _____________________________________________________16

Converter access ____________________________________________17

Flags and led interpretation___________________________________________17

Keyboard _________________________________________________________18

Blind version_______________________________________________________18

Start-up visualization pages___________________________________________19

Flow rate visualization _______________________________________________20

Access codes ______________________________________________________21

Quick start menu ___________________________________________________22

Access to the configuration menu ______________________________________23

Examples _________________________________________________________24

Programming functions _______________________________________26

Functions description________________________________________________29

Batch function confuguration___________________________________38

Alarm messages_____________________________________________40

Appendix: Display rotation procedure ____________________________41

Service: return form for instrument repair or calibration______________45

Conformity declaration________________________________________47

Addresses__________________________________________________48