2

252_EN_I S_1_3_00.doc

qI ntroduction _______________________________________________________________________________________ pag.3

§Symbols Used on the manual ____________________________________________________________________ pag.3

§Overall dimensions _____________________________________________________________________________ pag.4

qTechnical characteristics of converter ______________________________________________________________ pag.5

§Electrical characteristics_________________________________________________________________________ pag.5

§Environmental conditions of use__________________________________________________________________ pag.5

§Operative tem perature __________________________________________________________________________ pag.5

§Measure and consumption ______________________________________________________________________ pag.6

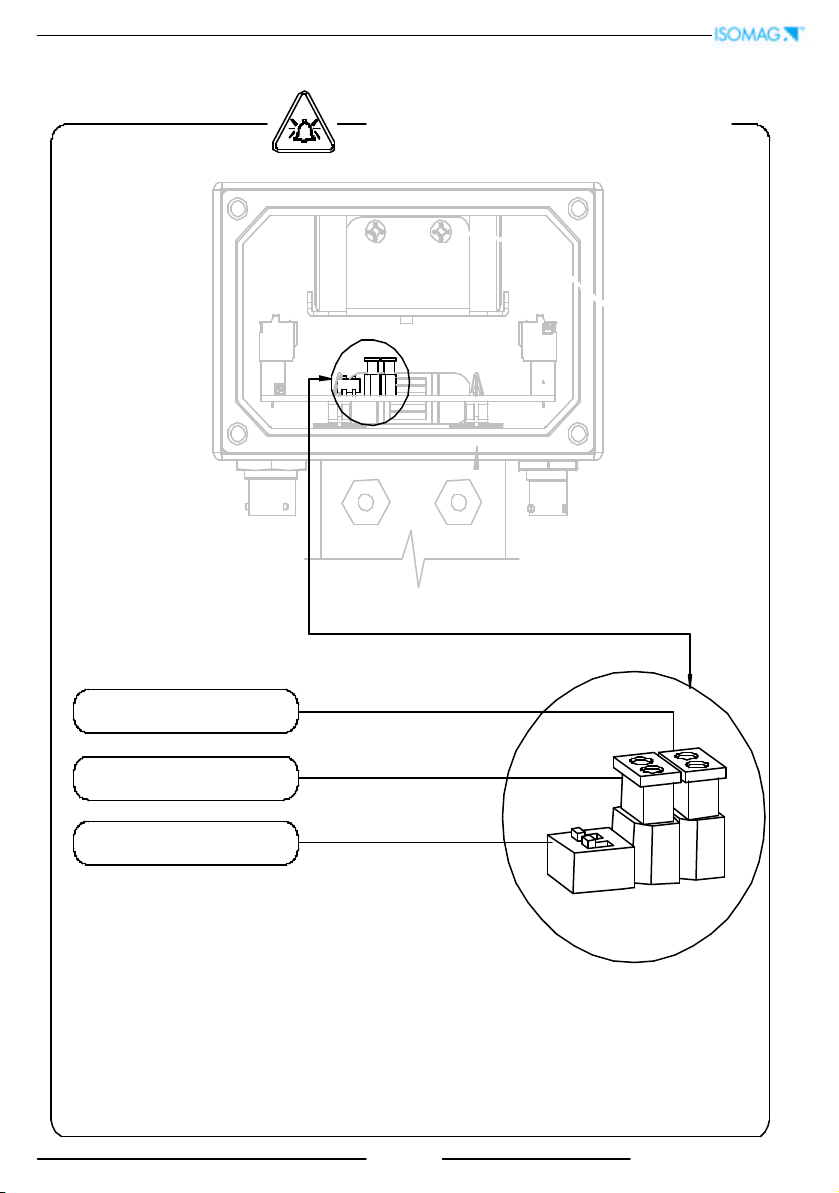

qElectrical connections______________________________________________________________________________ pag.7

§Out put on/ off 50Hz _____________________________________________________________________________ pag.7

qStart up and maintenance of the instruments_______________________________________________________ pag.8

§Device switch on ______________________________________________________________________________ pag.9

§Batteries power supply __________________________________________________________________________ pag.9

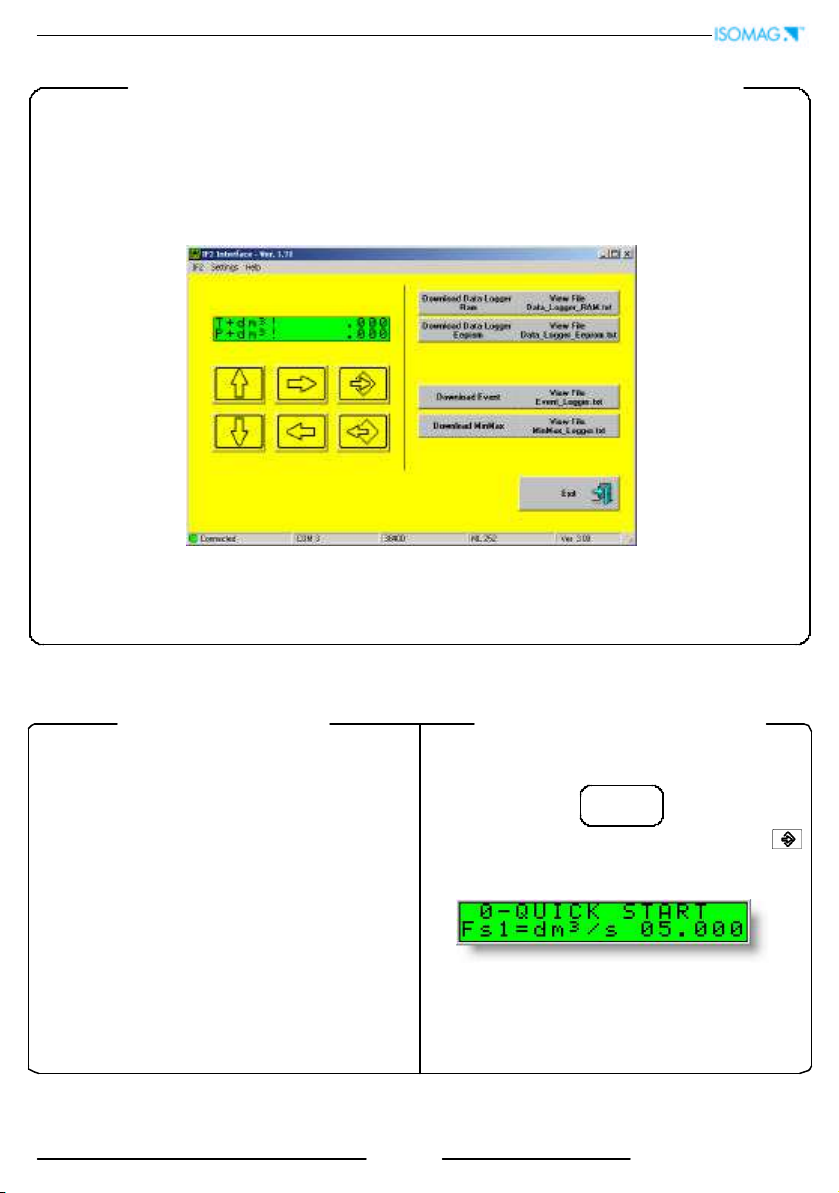

qHow to access at the instrument functions ________________________________________________________ pag.10

§User interface ________________________________________________________________________________ pag.10

§Access codes _________________________________________________________________________________ pag.10

§Converter visualisation pages __________________________________________________________________ pag.11

§Flags interpretation and led _____________________________________________________________________ pag.12

§Converter key board ___________________________________________________________________________ pag.13

§Functions description __________________________________________________________________________ pag.14

§Access to the configuration menu _______________________________________________________________ pag.17

qProgramming functions ___________________________________________________________________________ pag.19

§Functions description __________________________________________________________________________ pag.19

qAlarm messages __________________________________________________________________________________ pag.24

§Causes and action to be taken __________________________________________________________________ pag.24

§Anomalies codes ______________________________________________________________________________ pag.24

APPENDI X 1

Batteries substitution ______________________________________________________________________________________ pag.25

I NDEX