Page 2 of 26

Hydra 798 Iss.10 –04/18

CONTENTS

GUARANTEE.......................................................................................................................................................................... 3

ELECTRICAL SAFETY.................................................................................................................................................... 5

Environmental Ratings..................................................................................................................................................... 5

HEALTH AND SAFETY INSTRUCTIONS..................................................................................................................... 6

ON ARRIVAL.................................................................................................................................................................. 7

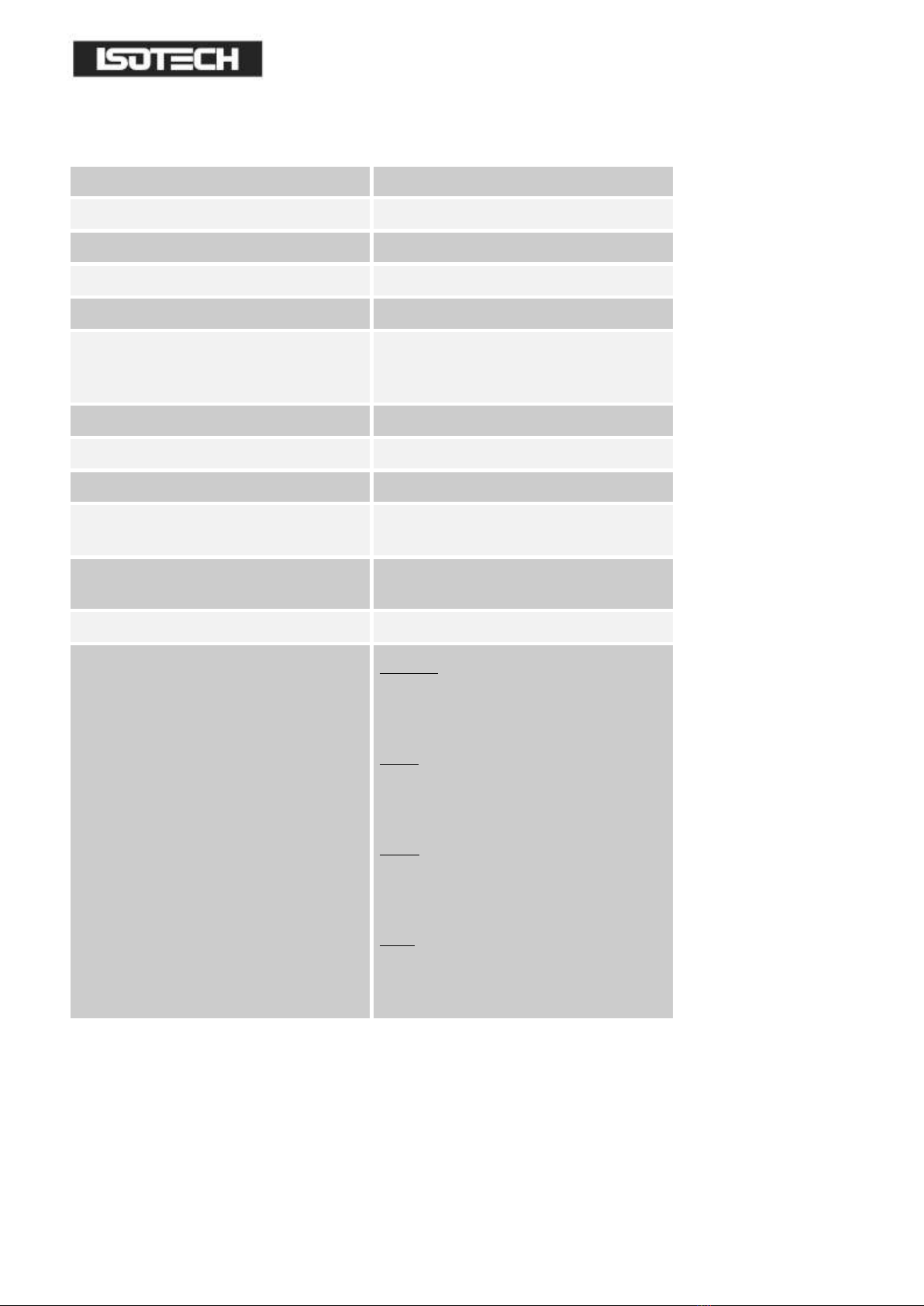

SPECIFICATION .................................................................................................................................................................... 8

FRONT PANEL CONTROLS................................................................................................................................................. 9

REAR PANEL ........................................................................................................................................................................ 10

IMPORTANT READ THIS NOW! ............................................................................................................................... 11

CHILLERS ......................................................................................................................................................................... 11

Chiller function - Medium ............................................................................................................................................. 11

Chiller function - Low ....................................................................................................................................................... 12

Chiller gases and quantities ........................................................................................................................................... 12

SETTING UP..................................................................................................................................................................... 12

USING THE CONTROLLER ................................................................................................................................................ 13

FRONT PANEL LAYOUT ................................................................................................................................................ 13

The Temperature Controller........................................................................................................................................ 13

Altering the Setpoint ..................................................................................................................................................... 13

ADVANCED CONTROLLER FEATURES........................................................................................................................ 13

Setpoint Ramp Rate....................................................................................................................................................... 13

Instrument Address....................................................................................................................................................... 14

MONITORING THE CONTROLLER STATUS ............................................................................................................... 14

Units.............................................................................................................................................................................. 14

OVER TEMPERATURE CONTROLLER (H MODEL ONLY) .......................................................................................... 15

OVER AND UNDER TEMPERATURE CONTROLLER (M & L MODELS) ..................................................................... 15

OVER TEMPERATURE CONDITION ............................................................................................................................. 15

UNITS ................................................................................................................................................................................... 17

DIAGNOSTIC ALARMS........................................................................................................................................................ 17

CONTROLLER ERROR MESSAGES................................................................................................................................. 17

OPERATION AND INITIAL TESTING ................................................................................................................................ 18

MOTOR NOTE .................................................................................................................................................................... 18

CHOICE OF LIQUIDS.......................................................................................................................................................... 19

LIQUID LEVEL.................................................................................................................................................................. 19

CHANGING LIQUIDS...................................................................................................................................................... 20

USING THE COOLING COIL ............................................................................................................................................. 21

CLEANING AND MAINTAINING THE BATH ................................................................................................................... 22

USING THE PC INTERFACE ............................................................................................................................................... 23

Connections ...................................................................................................................................................................... 23

Using the Interface ............................................................................................................................................................ 23

CAL NOTEPAD.................................................................................................................................................................... 24

Minimum System Requirements ....................................................................................................................................... 24

Development .................................................................................................................................................................... 24

Licence .............................................................................................................................................................................. 24

Installing Cal NotePad ....................................................................................................................................................... 25

Starting Cal NotePad ........................................................................................................................................................ 25

Protocol ............................................................................................................................................................................ 25

ACCESSORIES ...................................................................................................................................................................... 26