2. Guideline for connection and use of photometer

2. 1. Field of use

Photometer is designed for measuring and regulating illumination in traffic areas. It

provides adequate ilumination at any time of the day and any light conditions. Its basic

application is to regulate the illumination of tunnels and under passages based on L

20

measurement according to CIE standard. Photometer FM-1 is provided with analogue

U/I output for PLC or tunnel SCADA connection. For local illumination controll 4-channel

230VAC programmable outputs are available. Measuring range, output channel

switching and time averaging interval are PC programmable using provided software.

2. 2. Mounting and placement

Photometer is equipped with wall fixture. Pole fixture is also available (optional).

For measuring light conditions at the entrance of the tunnel the photometer is installed at

the stopping distance before entrance portal. It should be pointed directly to the entrance

of the tunnel.

When used to measure in-tunnel light conditions, the photometer should be mounted at

the height app. 4.5 metres and pointed to the spot one reach in 3 seconds at maximum

allowed speed. In this chase the driver’s view cannot be simulated very accurate due to

mounting height. Therefore, the measuring result must be adopted by multiplying with a

constant number (usually between 1.05 and 1.20).

Once mounted, undisturbed view field of the photometer must be provided. There should

be no disturbing objects in the view field of the photometer, either any light sources or

light reflecting objects in near distance. Any of these can considerably affect light

measuring accuracy.

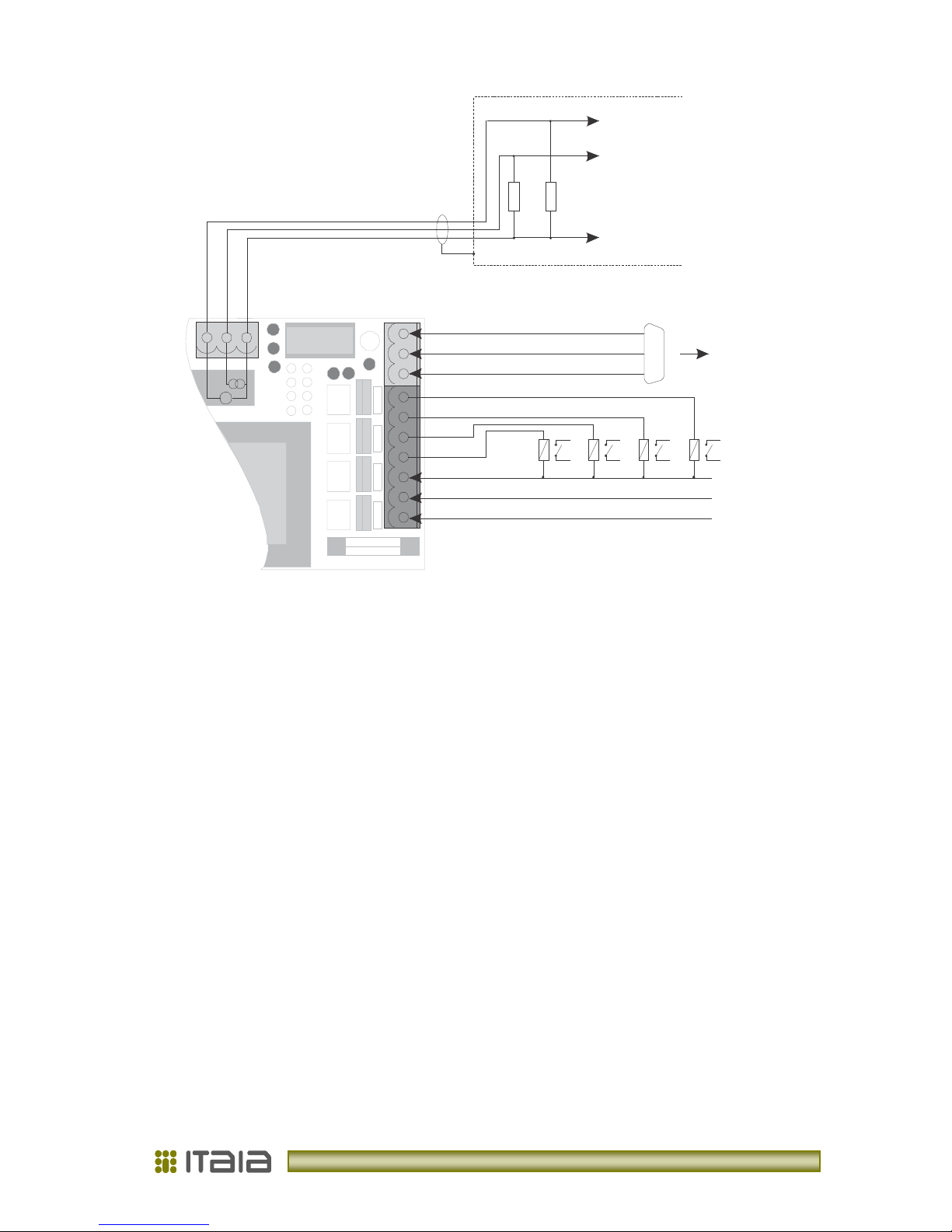

2. 3. Connecting

Photometer is connected to the mains power supply 230 VAC and to the tunnel light

regulating system. Cables with 3-7 leads at minimum 0.75 mm

2

must be used for 230 VAC

power outputs. For analogue U/I output coaxial 2-3 lead data cable is recommended.

Maximum connection distance is up to 400 metres. Cable inlet via glands must be well

tightened after the connection. For the parametric setup connect photometer with personal

computer and run software. Connection distance can be up to 20 metres for RS-232 (200 m

for RS-485 –optional).

All necessary connectors are accessible by removing rear cover (see Pictures 1 and 2and

Table 1).

After final connection and successful commition place provided desiccant bag in the

photometer housing and push it towards front window. Take care it is not touching any

electrical part!