To reduce the risk of fire or electrical shock please assure that :

All the operations requiring the removal of the cover must be carried out by

qualified personnel

1. IMPORTANT SAFETY INSTRUCTIONS

The appliance is disconnected from the mains before any form of

intervention.

The mains supply cabling and any extension cords are adequately sized,

according to the rated power of the pump and that there is no risk of the

electrical connections coming into contact with water.

Always use a Residual Current Device with IDn=30mA particularly in

installations pertaining to swimming pools, ponds or fountains.

CAUTION: When the pump stops, the system will still be under pressure, therefore, before

any intervention, make sure to open a tap to relieve the system.

The device should only be used for clean water systems and is not suitable for use with

sea water, sewage, drainage systems, explosive, corrosive or any other hazardous liquids.

2. WARRANTY

The manufacturer guarantees this product for a period of 24 months from the date of

purchase; the unit must be returned together with this instruction manual, clearly indicating

the date of installation on the last page.

The warranty is automatically annulled if the appliance is subjected to any form of

unauthorized tampering, damage resulting from incorrect use and/or improper installation,

unsuitable environmental conditions or improper electrical installation.

The manufacturer declines any form of liability resulting from damages to buildings,

personal belongings and/or persons, caused by failure to install the necessary electrical

protection devices or inferior workmanship.It is strongly recommended that the installation

and maintenance of this appliance be undertaken by qualified electricians, who are

expected to fully understand the contents of this instruction manual.

The manufacturer cannot be held responsible for any kind of damage to people and/or

things ensuing from the failure of any internal safety devices to intervene, with the

exception of compensation for the device itself if still under guarantee.

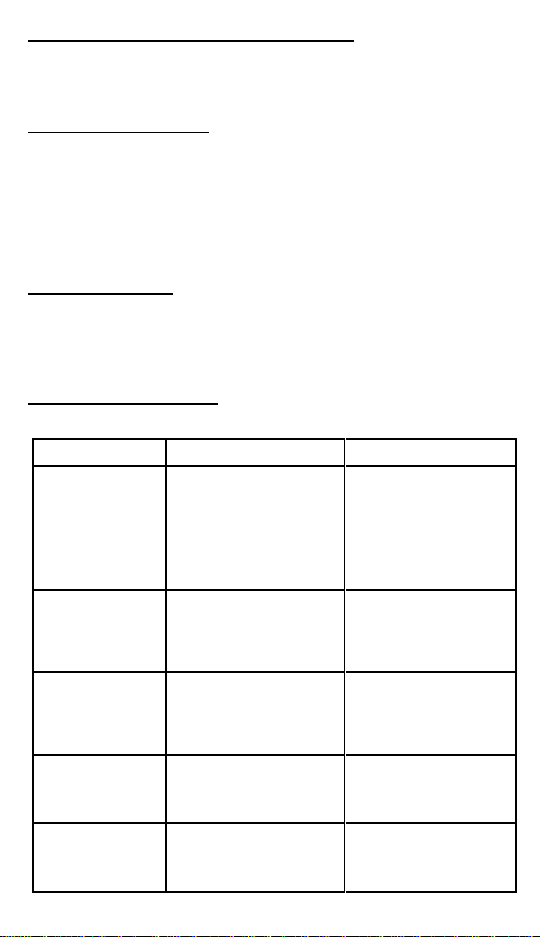

3.TECHNICAL DATA

Power Supply: ... ... ... ... ... ... .............115-230VAC ± 10% 50/60 Hz(Brio Green 230VAC)

Max current: ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12 A

Cut-. 1 ÷ 3.5 bar

10 bar

W..°÷55°C

.5°C

°C

...................-10÷50°C

Type ( Ref. EN 60730-................1.C

..............III

Insulatio...III

Nm