Green Heating Technology

2

Table of Content

Safety warnings 3

Safety warnings symbols legend � � � � � � � � � � � � 4

References to Laws and Norms � � � � � � � � � � � � � 4

Personnel in charge of installaon � � � � � � � � � � � � � 4

Installaon, use and maintenance � � � � � � � � � � � � � 4

User warnings � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Important � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

First starng up and Use � � � � � � � � � � � � � � � � � � � � � 5

Installaon, rst starng up, maintenance and

servicing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Appliance booklet or central plant booklet � � � � � � 6

Combuson checking � � � � � � � � � � � � � � � � � � � � � � � � 6

Boiler operaon and servicing � � � � � � � � � � � � � � � � � 6

User guide 7

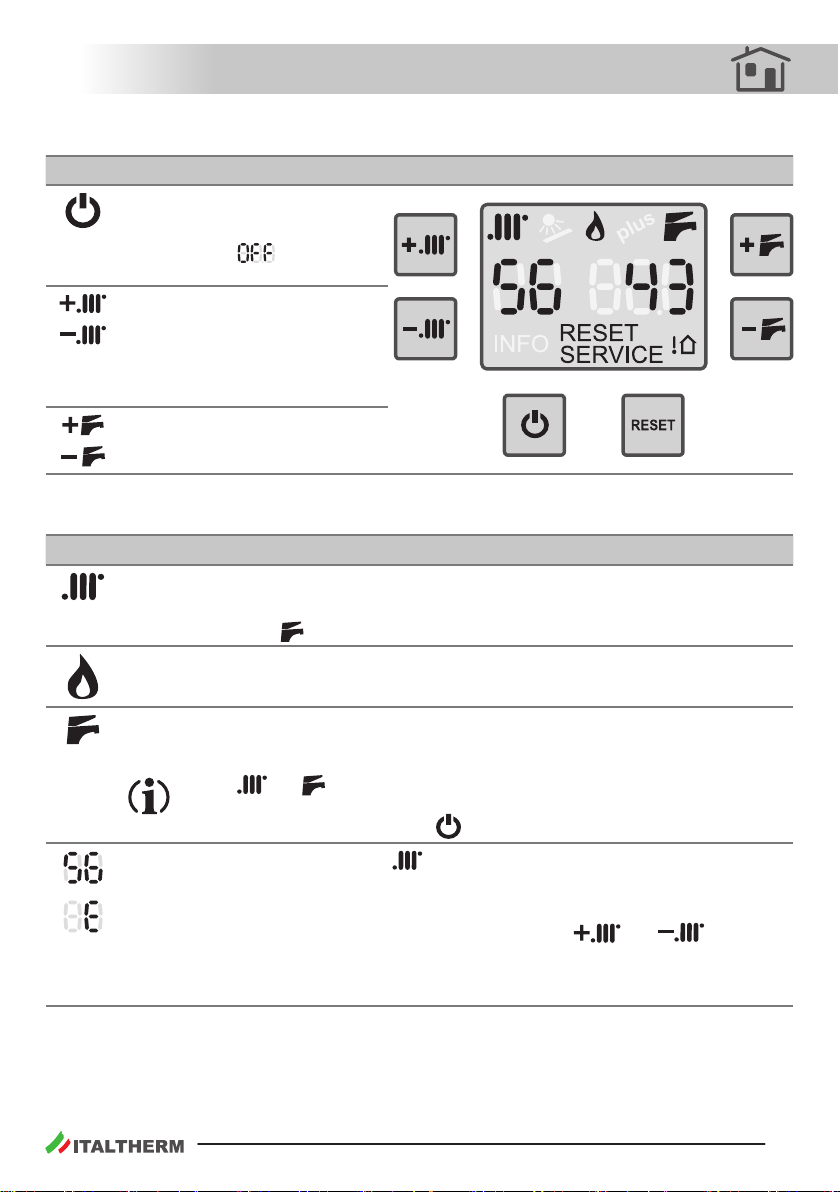

The front control panel � � � � � � � � � � � � � � � � � � � � 7

Commands on the lower side � � � � � � � � � � � � � � 8

Commands outside the boiler � � � � � � � � � � � � � � 8

Typical use � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Preliminary operaons � � � � � � � � � � � � � � � � � � � � � � � 9

Boiler acvaon � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Temperature adjustment � � � � � � � � � � � � � � � � � � � � � 9

Incidental malfunconing � � � � � � � � � � � � � � � � 10

The burner doesn’t turn on � � � � � � � � � � � � � � � � � � 10

Shortage of domesc hot water producon � � � � 10

Boiler inacvity � � � � � � � � � � � � � � � � � � � � � � � � � 11

Safety shut o � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Stand-by mode with an-frost & an-locking

funcon � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

“Ambient An-Frost” Funcon � � � � � � � � � � � � � � � 12

Installaon 12

Law and regulaon prescripons for the

installer � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

Dimensions and connecons � � � � � � � � � � � � � � 13

Pump capacity diagram � � � � � � � � � � � � � � � � � � 13

Warnings for the installaon of oponal kits

or special systems � � � � � � � � � � � � � � � � � � � � � 14

Floor heang system � � � � � � � � � � � � � � � � � � � � � � � 14

Specicaons for intake air � � � � � � � � � � � � � � � 14

Domesc water supply characteriscs � � � � � � 15

Protecon against freezing � � � � � � � � � � � � � � � 15

Outdoor installaon in a parally protected

place � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Posioning and fastening � � � � � � � � � � � � � � � � � 16

Hydraulic system (DHW and heang) � � � � � � � 17

Advices and suggesons to avoid vibraons and

noises in the system � � � � � � � � � � � � � � � � � � � � � � 17

Cleaning and preservaon of the systems � � � � � � 17

Heang system � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Condense drain � � � � � � � � � � � � � � � � � � � � � � � � � 18

Heang system lling and pressuring � � � � � � � 18

Gas connecon � � � � � � � � � � � � � � � � � � � � � � � � � 19

Electrical connecons � � � � � � � � � � � � � � � � � � � � 20

Flue systems � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Intake/outlet ange � � � � � � � � � � � � � � � � � � � � � � � � 21

Installaon of the ue intake/outlet ange

gasket � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

General indicaons � � � � � � � � � � � � � � � � � � � � � � � � � 21

Examples of installaon of intake and outlet

ducts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Dimensioning the intake and outlet ducts � � � � � � 24

Flue system types � � � � � � � � � � � � � � � � � � � � � � � � � � 25

Allowed ue types � � � � � � � � � � � � � � � � � � � � � � � � � 26

Adjustment and Maintenance 27

First starng up � � � � � � � � � � � � � � � � � � � � � � � � � 27

Maintenance operaons � � � � � � � � � � � � � � � � � 28

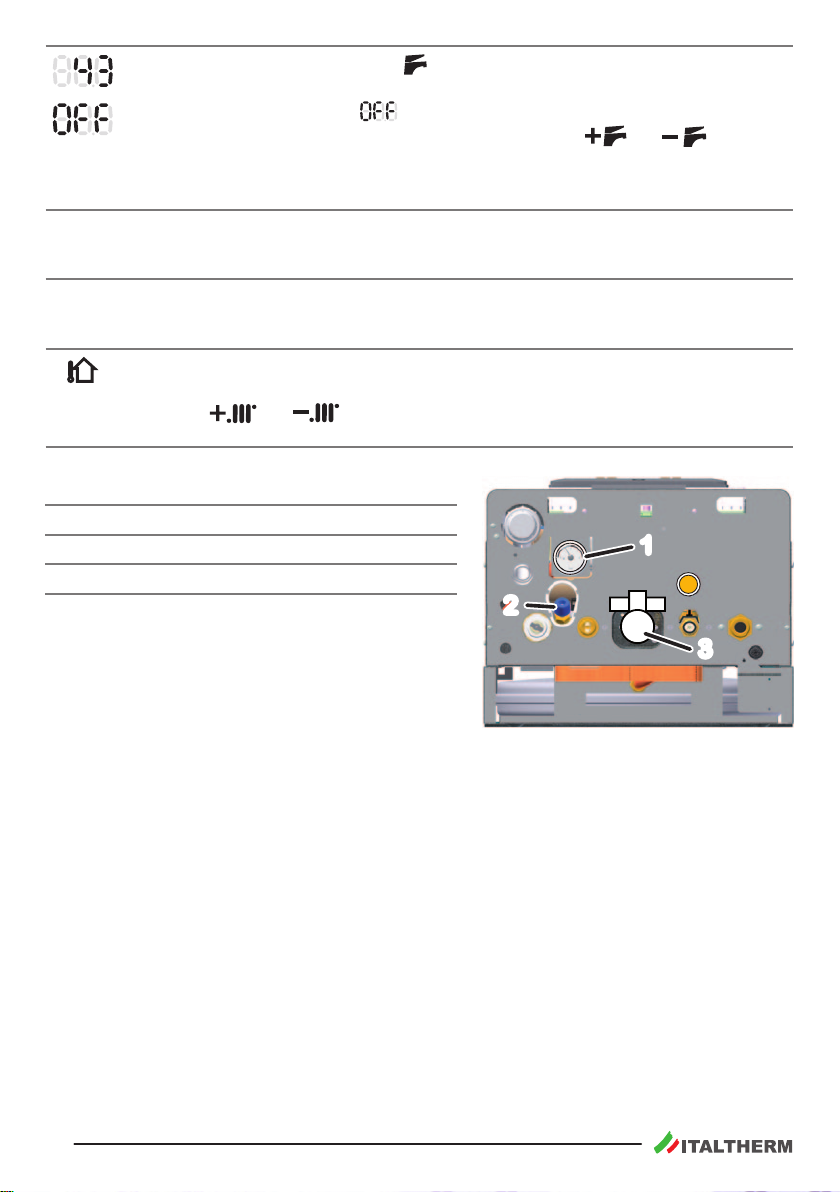

Access to the inside of the boiler � � � � � � � � � � 29

Venng the primary exchanger � � � � � � � � � � � � 30

Combuson group cleaning and check � � � � � � 30

PCB parameters sengs (technician menu) � � 31

Main boiler parameters (PC) � � � � � � � � � � � � � � � � � 32

Combuson test � � � � � � � � � � � � � � � � � � � � � � � � 35

Power adjustment tables � � � � � � � � � � � � � � � � � 36

Max heang power adjustment � � � � � � � � � � � 37

Combuson calibraon � � � � � � � � � � � � � � � � � � 37

Accessing the main board � � � � � � � � � � � � � � � � 38

Main board replacement � � � � � � � � � � � � � � � � � 38

Board conguraon codes � � � � � � � � � � � � � � � � � � � 38

Gas conversion � � � � � � � � � � � � � � � � � � � � � � � � � 39

Draining the heang system � � � � � � � � � � � � � � 40

Pump sengs � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Alarms - boiler block � � � � � � � � � � � � � � � � � � � � � 41

Warnings for servicing � � � � � � � � � � � � � � � � � � � 46

Technical data � � � � � � � � � � � � � � � � � � � � � � � � � � 47

Boiler internal components � � � � � � � � � � � � � � � 49

Electrical diagram � � � � � � � � � � � � � � � � � � � � � � � 50

Hydraulic diagram � � � � � � � � � � � � � � � � � � � � � � � 51

Addendum 52

Outdoor Sensor Kit � � � � � � � � � � � � � � � � � � � � � � 52

Installaon and seng � � � � � � � � � � � � � � � � � � � � � � 52

Outdoor Sensor kit and Remote Control � � � � � � � 52

Remote Control Kit � � � � � � � � � � � � � � � � � � � � � � 53