ITC Dositec MP User manual

Other ITC Water Pump manuals

ITC

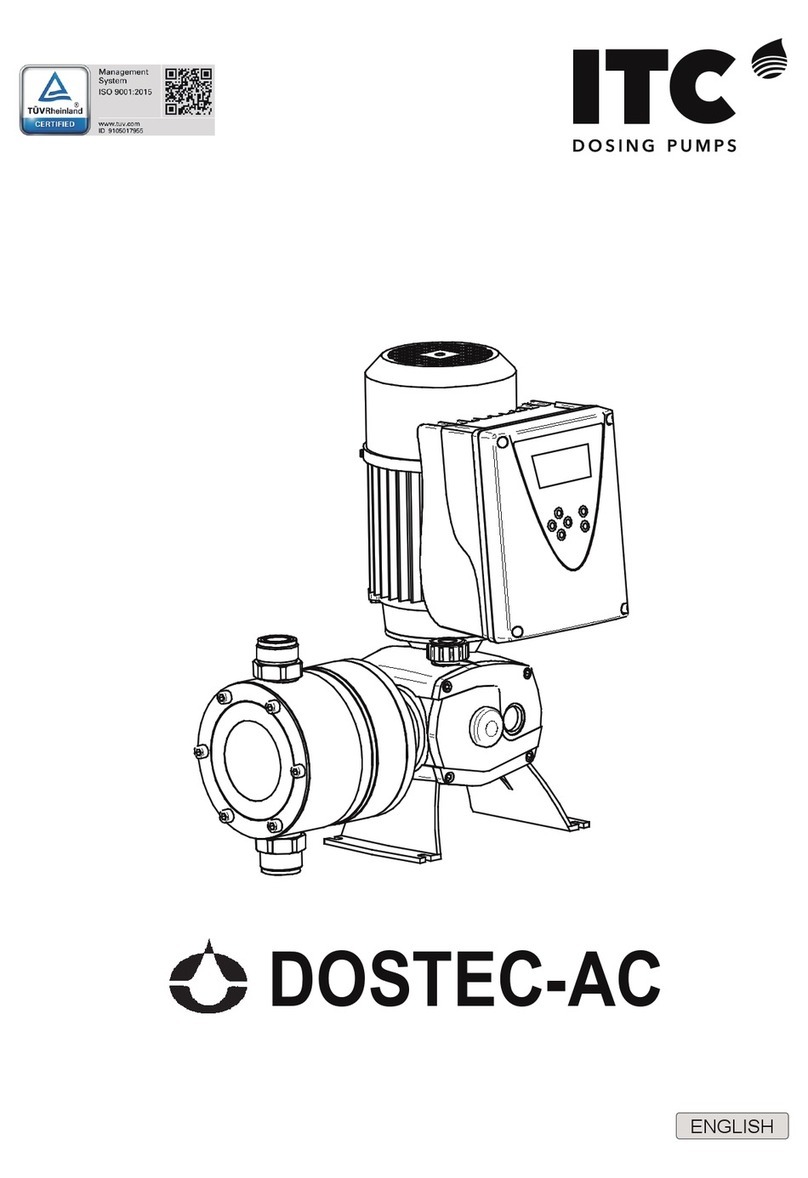

ITC DOSTEC AC User manual

ITC

ITC DOSTEC-AC Operation instructions

ITC

ITC GATE User manual

ITC

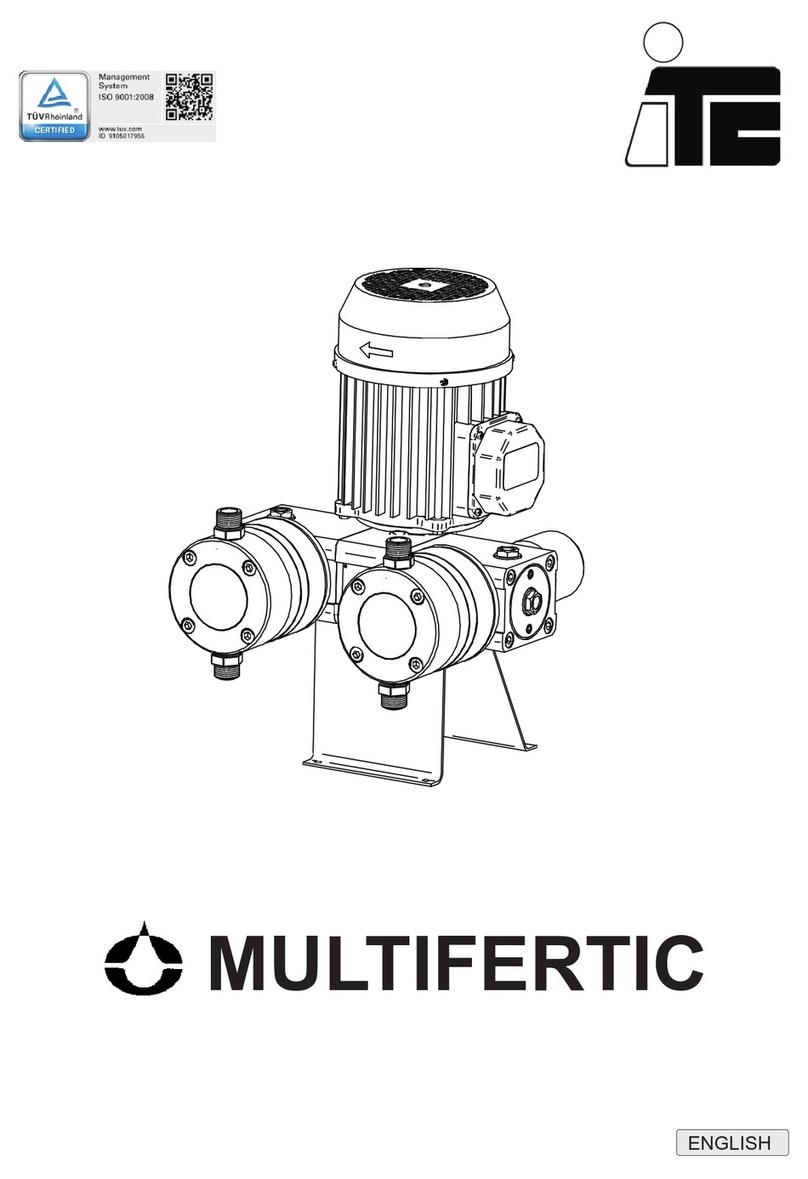

ITC TRIANGLE WATERQUIP MULTIFERTIC MF User manual

ITC

ITC MULTIFERTIC User manual

ITC

ITC DOSmart AC S50-D50 User manual

ITC

ITC TEKDOS FP Series Operation instructions

ITC

ITC DOSTEC-50 User manual

ITC

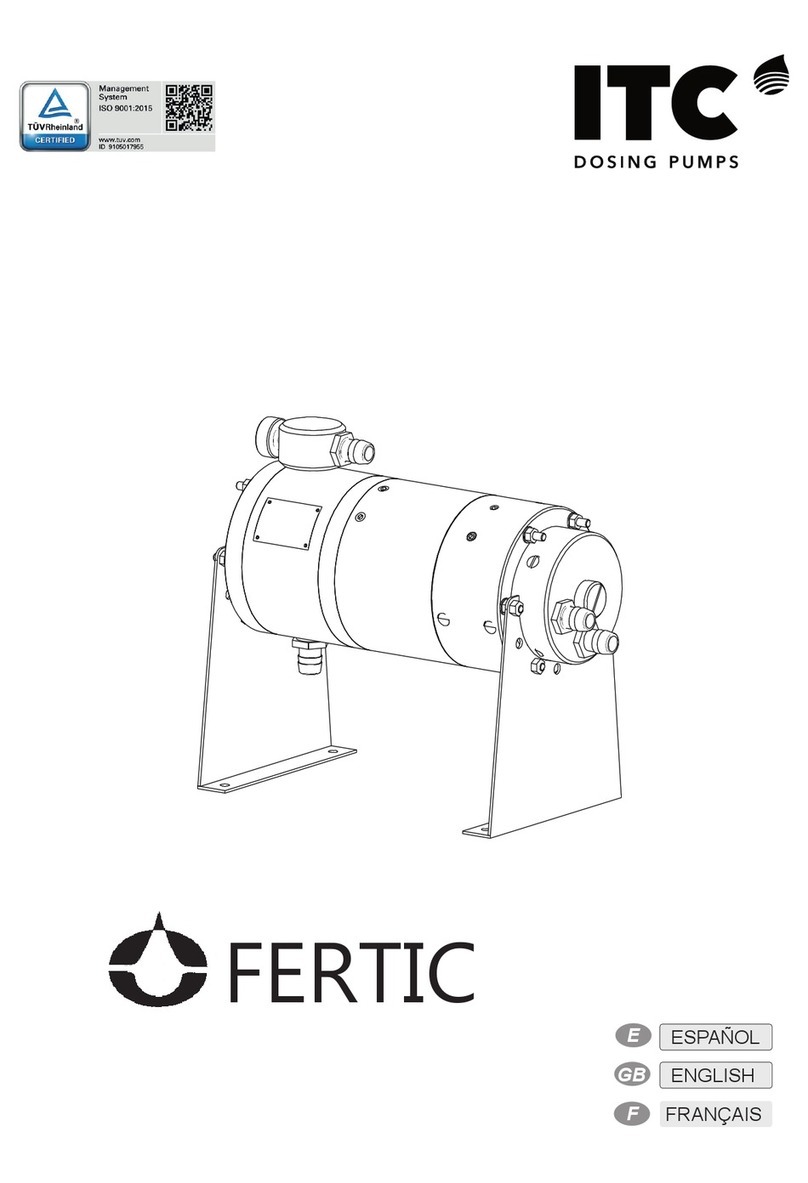

ITC FERTIC User manual

ITC

ITC DOSTEC AC User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual