4

1.- GENERAL DESCRIPTION

MULTIFERTIC dosing pumps are heavy duty, high precission electric piston or

diapragm pumps for dosing liquid products.

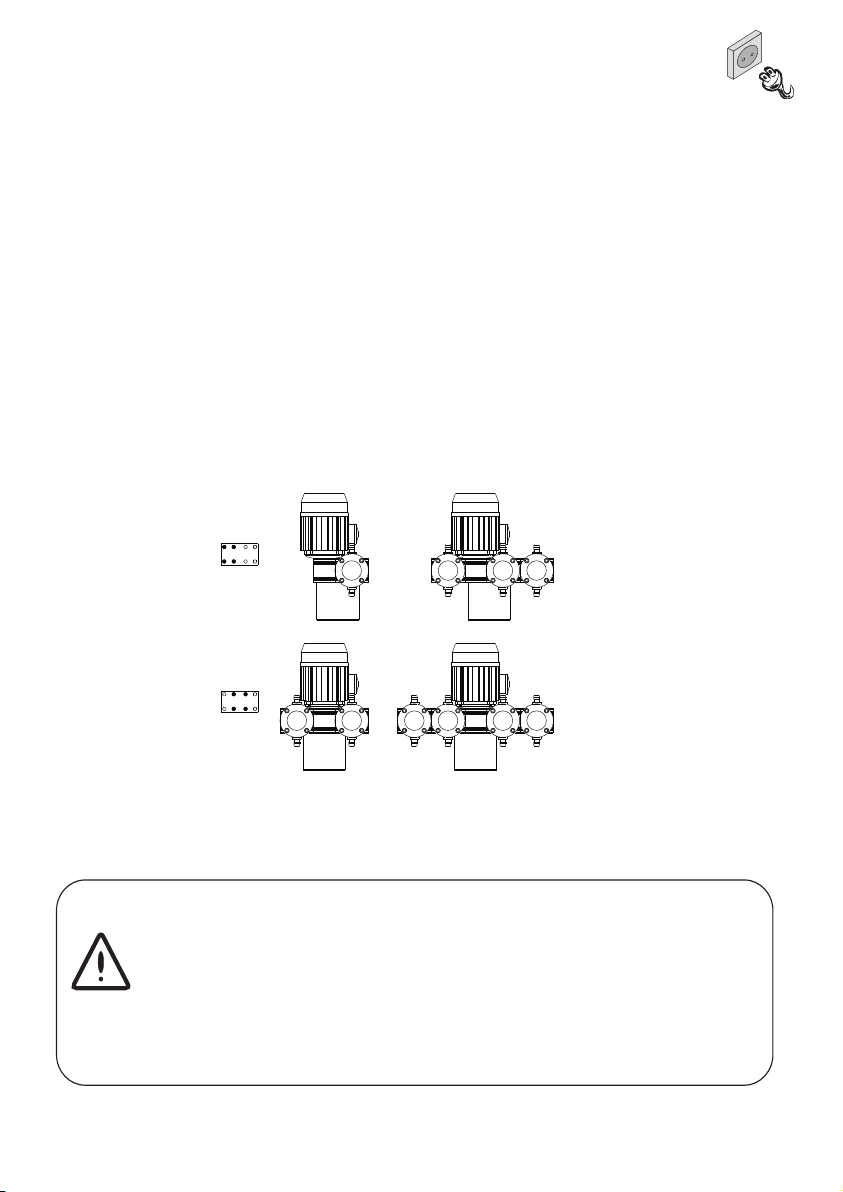

They are made up of one driving module and 1 to 4 injection modules. The

available heads are from 25 to 500 l/h for the piston series, and from 18 to 300

l/h for the diafragm series,independently regulated by means of a system of

POSITIVE RETURN, exclusive to I.T.C.

In the same injector can be connected several injection modules to apportion

different products (INDEPENDENT INJECTION) or to increase the injection

flow. The design of this dosing pump allows the combination of piston modules

with diaphragm modules in the same pump. By increasing the number of

modules in the same injector, a higher flow regularity is obtained, whereby in

the 4 module model an actually continuous flow is obtained. Injection modules

may be connected in the factory or added later when the injector is in place.

MULTIFERTIC dosing pumps are manufactured with materials that can resist

the existing agrochemical products, even acids. It is designed for all sorts of

processes where it is necessary to dose a product into a hydraulic network,

such as: food, textile, chemical industry, water treatments, etc. (See materials

in Technical Features). In case there is any doubt about compatibility of

materials with the products to be used please contact with ITC S.L. Technical

Service.

Dosing flow of each module is adjustable independently with no need to stop

the pump from 0% to 100% of its capacity.

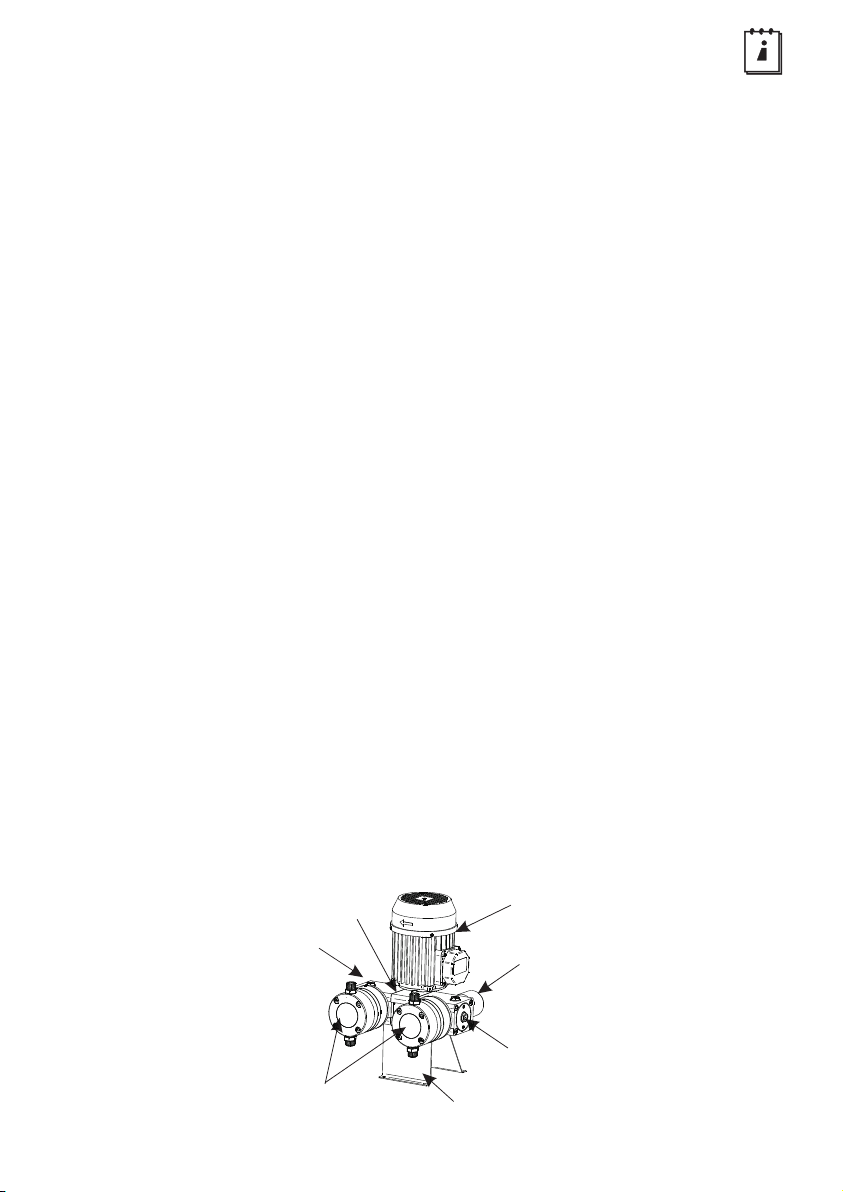

It is made up as follows:

Motor

Cylinder

Motor module

Additional module

Support

Regulator

Motor block

5

Codes formulation

62 - A 2 1 - B P 0 P M

MOTORMOTOR REDUCCIÓN

2: 2 cycles.

1: 1 cycle.

FREQUENCY

P: PP - PEUHMW / PTFE

C: PP - Ceramic / PTFE

I : AISI316 - Ceramic / PTFE

F: PVDF - Ceramic / PTFE

T: PTFE - Ceramic / PTFE

A: PP - AISI316 /

MATERIAL

Cylinder - Piston / Diaphragm

62 - S P 0 P M

M: 3/4"

S: ADDITIONAL MODULE

A: 3Ph 230/400V

B: 1Ph 230V 50Hz

C: 1Ph 110/230V 60Hz

D: 12V DC 130W

E: 12V DC 300W

F: 24V DC 130W

G: 24V DC 300W

B: MAIN MODULE

Q0: Piston 25 (1 cycle)

P0: Piston 50 (2 cycles)

P1: Piston 100 (2 cycles)

P2: Piston 200 (2 cycles)

P3: Piston 300 (2 cycles)

P5: Piston 500 (2 cycles)

F0: Diaphragm 25 (1 cycle)

D0: Diaphragm 50 (2 cycles)

D1: Diaphragm 100 (2 cycles)

D2: Diaphragm 200 (2 cycles)

D3: Diaphragm 300 (2 cycles)

CAUDAL

FLOW

CONEXION

Q0: Piston 25 (1 cycle)

P0: Piston 50 (2 cycles)

P1: Piston 100 (2 cycles)

P2: Piston 200 (2 cycles)

P3: Piston 300 (2 cycles)

P5: Piston 500 (2 cycles)

F0: Diaphragm 25 (1 cycle)

D0: Diaphragm 50 (2 cycles)

D1: Diaphragm 100 (2 cycles)

D2: Diaphragm 200 (2 cycles)

D3: Diaphragm 300 (2 cycles)

CAUDAL

P: PP - PEUHMW / PTFE

C: PP - Ceramic / PTFE

I : AISI316 - Ceramic / PTFE

F: PVDF - Ceramic / PTFE

T: PTFE - Ceramic / PTFE

A: PP - AISI316 /

MATERIAL

Cylinder - Piston / Diaphragm M: 3/4"

FLOW CONEXION

62 - ENS 2

CAUDAL

ASSEMBLY

1: 1 Modue

2

3: 3 Modules

4: 4 Modules

: 2 Modules

NUMBER OF MODULE