Page iv

Revised 11/14

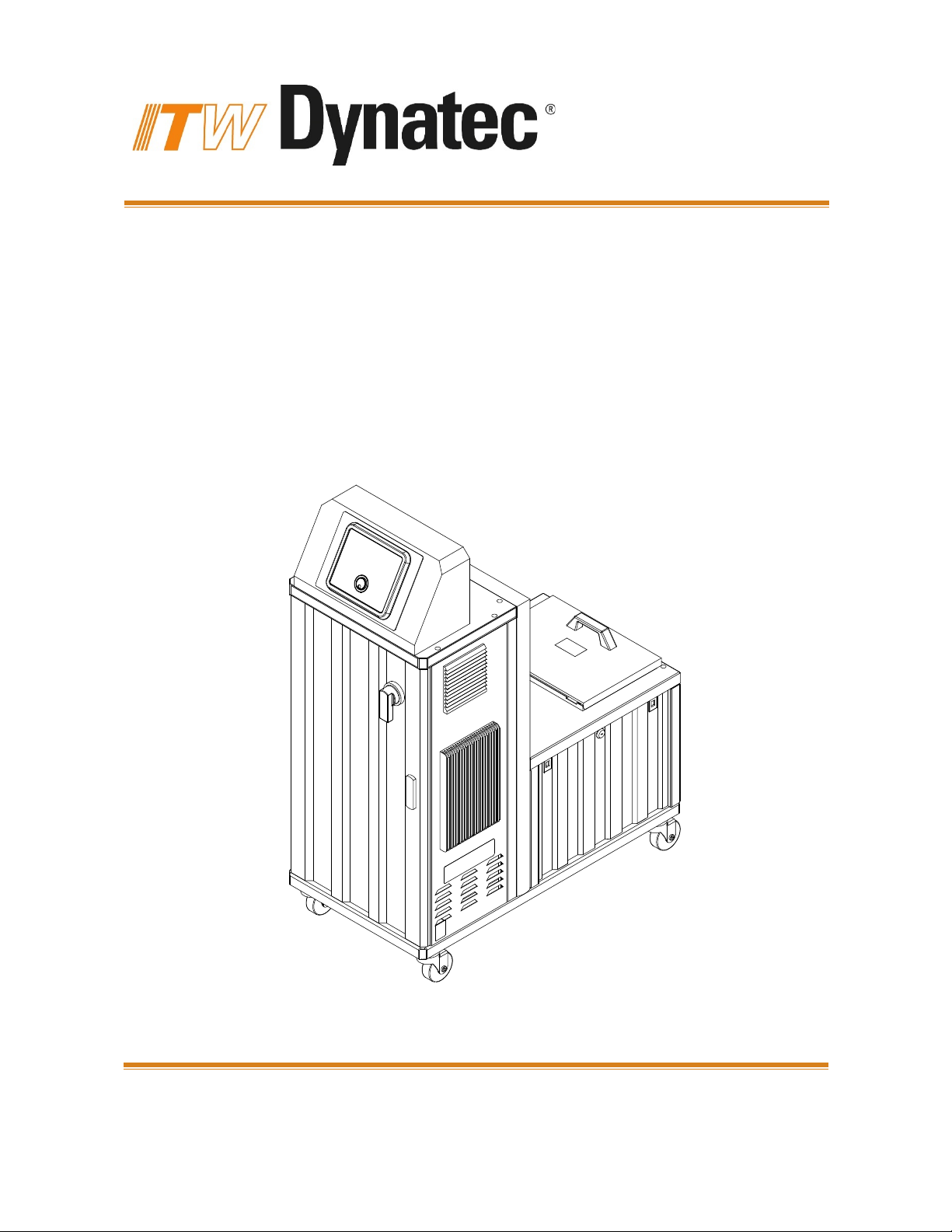

ITW Dynatec

D15/D25/D45 V6 DCL ASU Manual #20-63

LCD Controller Features 4-10..............................................................

Helpful Tips for the User 4-10..............................................................

Chapter 5 Programming of DynaControl Controllers

LCD HMI PROGRAMMING Section 1..................................................................

DynaControl V6 LCD Interface 5-1........................................................

In General 5-1..........................................................................

Overview Screen Reference 5-2............................................................

Status Line 5-3.........................................................................

Temperature Zone Symbols 5-3............................................................

Bar Graphs 5-4.........................................................................

Scan Mode 5-4.........................................................................

To Navigate Away from Overview Screen 5-5................................................

Setup Your System Parameters 5-6.........................................................

Temperature Zones 5-6...................................................................

Pump Settings 5-8......................................................................

Main Menu 5-10.........................................................................

Recipe Management 5-10..............................................................

Standby/ Setback 5-11................................................................

Setpoint Locking 5-12.................................................................

7-Day Scheduler 5-12.................................................................

Current Time-of-Day and Day-of-Week 5-14...............................................

Info Screen 5-15.....................................................................

System Configuration Menu 5-16...........................................................

Accessing the Parameters 5-16..........................................................

Temperature Unit (Celsius or Fahrenheit) 5-17.............................................

Language Selection 5-17...............................................................

Zone Configuration 5-17...............................................................

Pump Configuration 5-17..............................................................

Setpoint Limitation 5-18...............................................................

Hi/Lo Alarm Tolerance 5-18............................................................

Standby Configuration 5-18............................................................

Level Detection 5-19..................................................................

Heatup Sequence (Priority) 5-20........................................................

Access Code 5-21....................................................................

0.5 RPM Increment 5-21...............................................................

Temperature Offset 5-21...............................................................

Customer Zone Names 5-22............................................................

Logbook/ Fault History 5-23...........................................................

Power-On Configuration 5-24..........................................................

Global Setpoints 5-25.................................................................

Controller Messages Troubleshooting Guide 5-26..............................................

TOUCH SCREEN HMI PROGRAMMING Section 2......................................................

Setup Your System’s Parameters 5-29........................................................

Input Keyboard 5-29.....................................................................

Main Screen 5-30........................................................................

Temperature Zones Set Screen 5-34..........................................................

Pump Overview Screen 5-35...............................................................

Pump Control, Linear Line Speed 5-36.......................................................

Extended Pump Mode Settings, Linear Line Speed, Pressure Control 5-38...........................

Pump Control, Pressure Control Screen 5-40..................................................

Automatic Ramp Compensation (ARC) 5-42..................................................