About this Document

5

1 About this Document

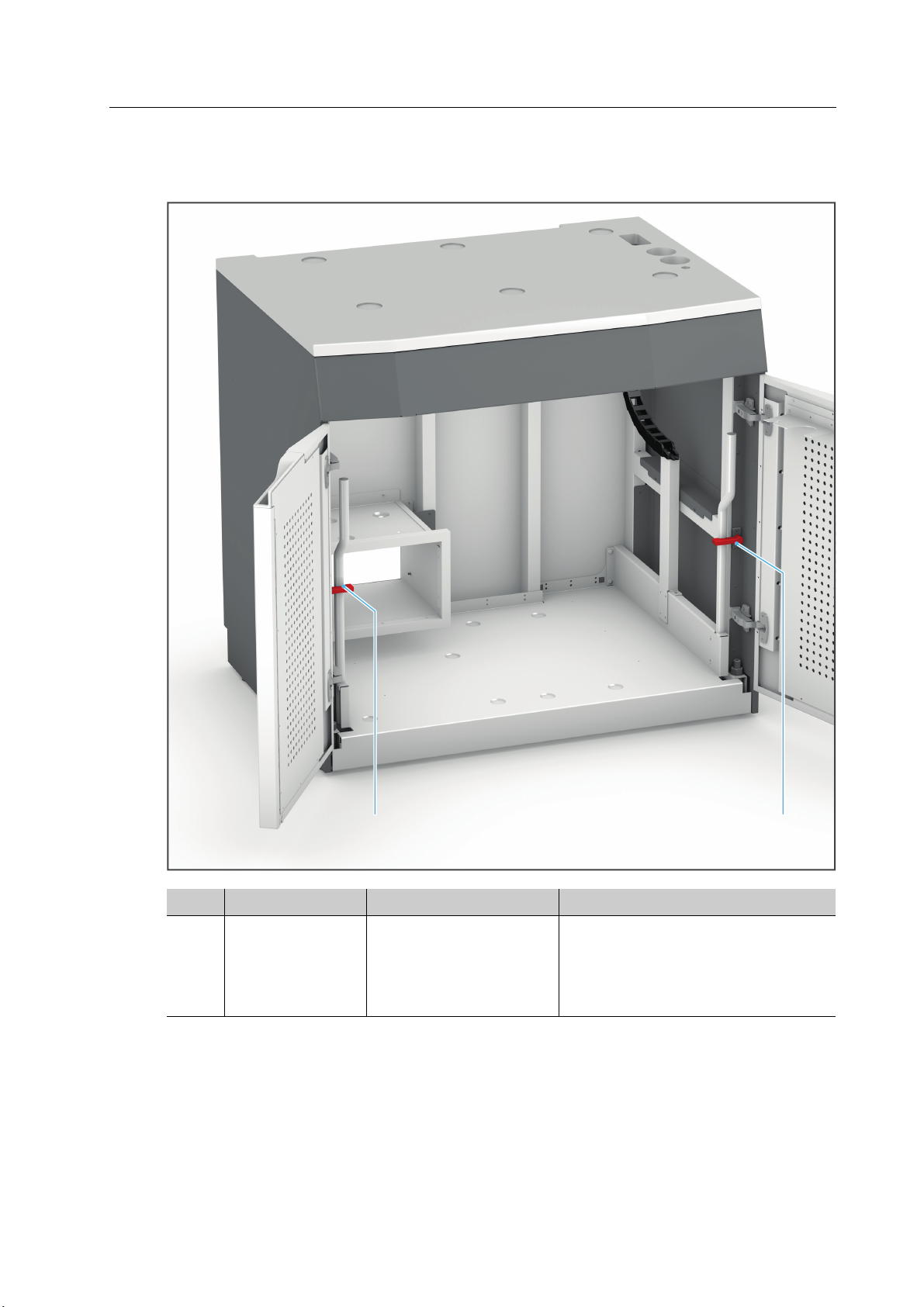

These Operating Instructions will familiarize you with the PrograMill Base features. The

PrograMill Base will be referred to as “base cabinet” from now on.

This product is a cabinet for accessories, tools and discs / blocks from the PrograMill milling

systems.

The Operating Instructions are an integral part of the product. They describe the safe and

correct use in all operating processes.

Improper use can be dangerous. Please observe the relevant safety instructions and read the

Operating Instructions carefully.

These Operating Instructions only apply together with the Operating Instructions from the

milling systems PrograMill PM3, PM5 and PM7 (“Supporting documents”, page 7). Read the

instructions carefully before using PrograMill Base, in particular the chapter regarding safety

instructions and warnings.

Should you lose these Operating Instructions, you can download them from

www.ivoclarvivadent.com.

For all types of technical questions, please contact your authorized service partner.

1.1 Target groups

Target group Duties

Operator •Keep these Operating Instructions

available at the place where the unit is

operated, also for future use.

•Request personnel read and observe

these instructions and the applicable

documents included. This applies in

particular for the safety instructions and

warnings (“Safety”, page 8).

•Observe additional product-related

stipulations and regulations.

Dental technician •Read and observe these Operating

Instructions and the applicable

documents, in particular safety

instructions and warnings (“Safety”,

page 8).

Qualified dental staff

CNC technician

Authorized Ivoclar Vivadent service partner