Ixtur Ltd / MAP-6

Holding Force

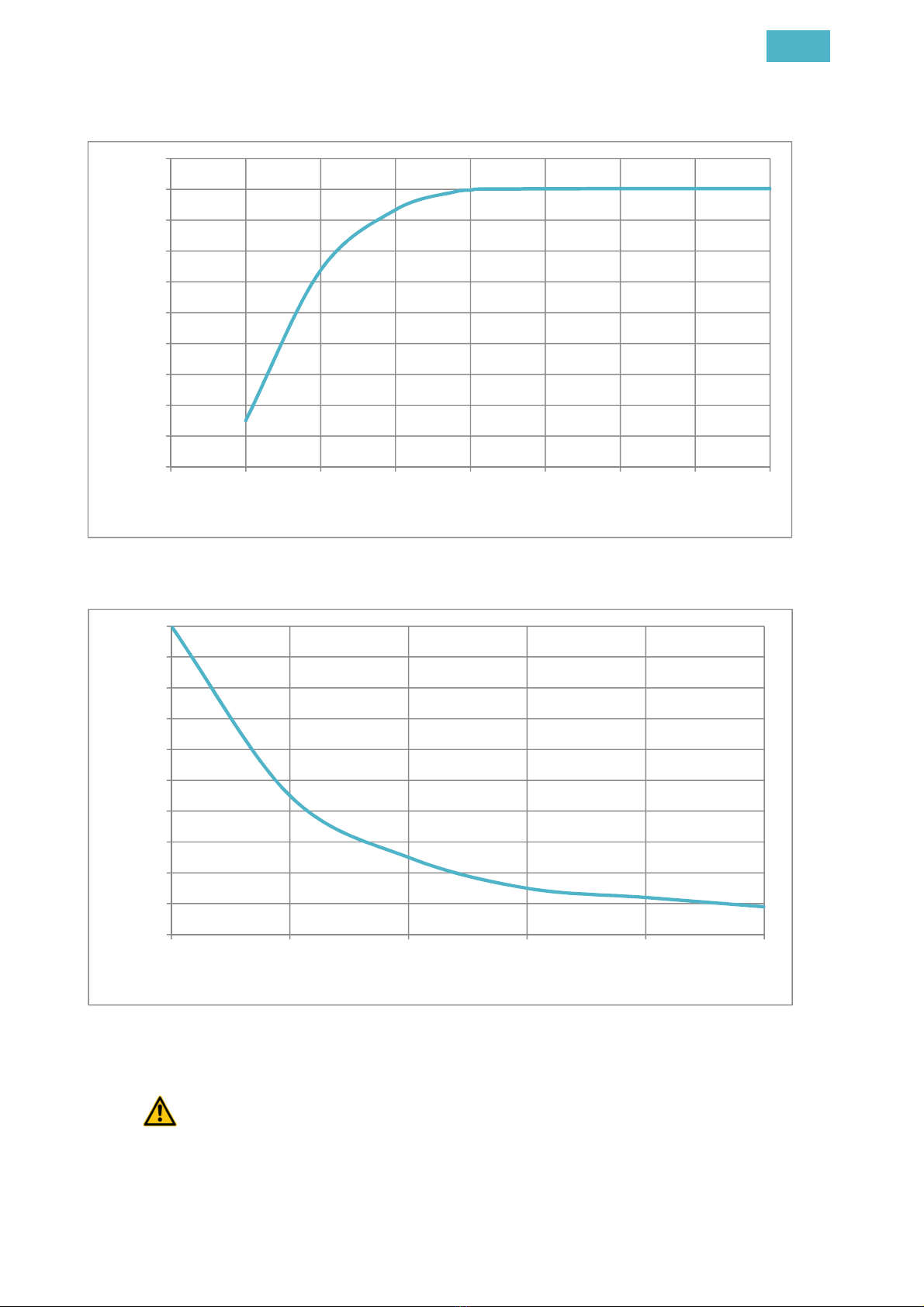

Holding force and rated lifting capacity of MAP-6 can only be applied when the forces are perpen-

dicular to the magnet's gripping surface.

Three factors affect magnet’s holding force:

-Material properties

-Thickness of the load

-Distance between gripping surface and attached load (airgap)

Holding force and lifting capacity of MAP-6 pneumatic magnet are rated with steel EN S235. Most

other steel materials produce lower holding force. Also hardened steel produces lower holding

force.

Material’s capacity to conduct magnetic field depends on its thickness. A thinner material has

weaker capacity compared to a thicker material. Increasing material thickness increases the mate-

rial’s capability to conduct magnetic field until a magnet specific maximum value is reached. See

figure 2: MAP-6 holding force in proportion to material thickness

Any material that separates the magnet's gripping surface from the surface of the load reduces the

total magnetic holding force. Reduction can be caused by non-magnetic materials or by materials

with weak magnetic qualities, such as, zinc or paint or similar coating, rust, frost or air. The dis-

tance between the surfaces caused by materials above is commonly called as airgap.

Surfaces must be clean and the airgap zero to achieve maximum holding force. The load surface

must also be flat and it must occupy the gripping surface of the device completely. See figure 3:

MAP-6 holding force in proportion to airgap.

Figure 1. The gripping surface and magnetic poles of MAP-6.