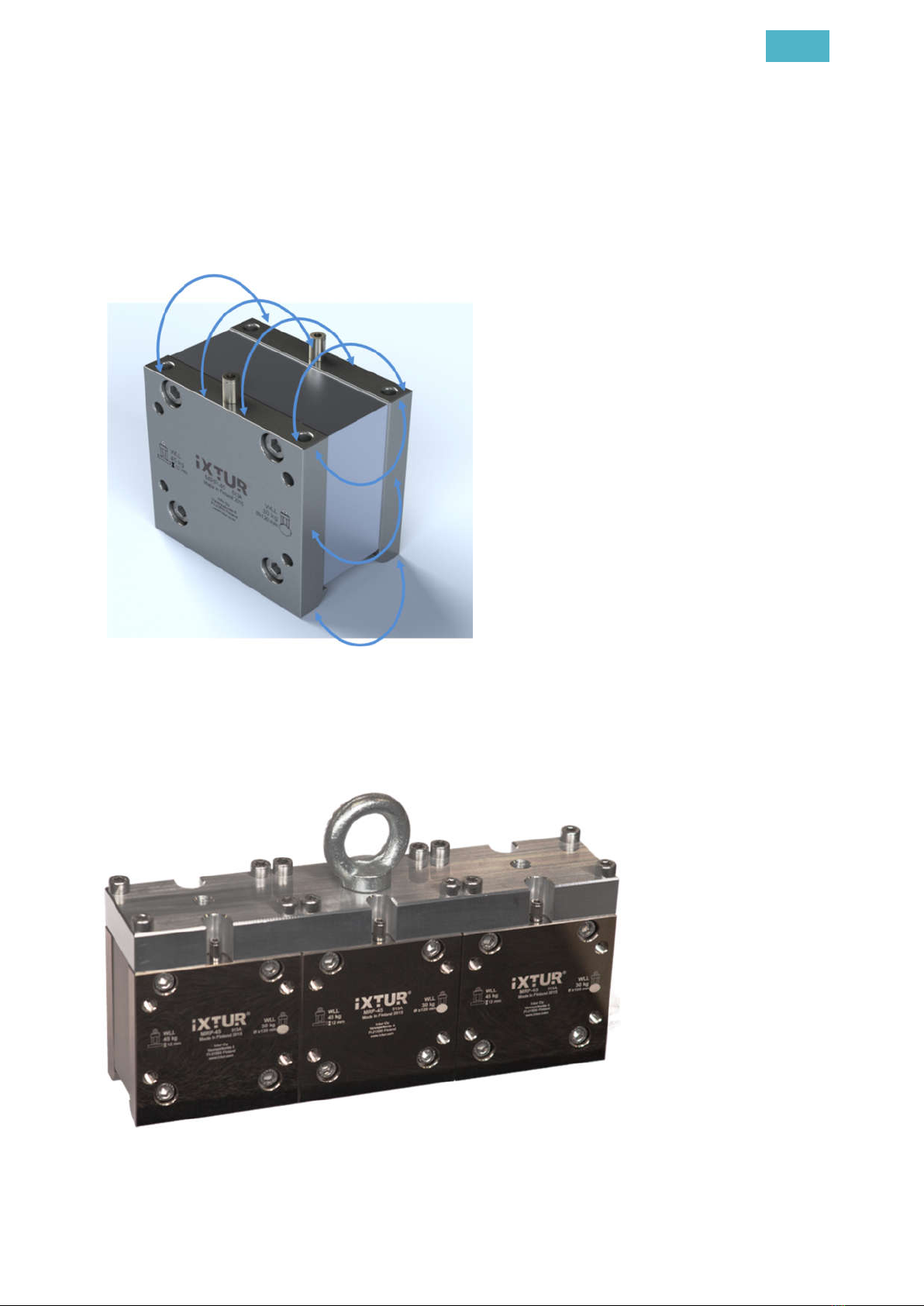

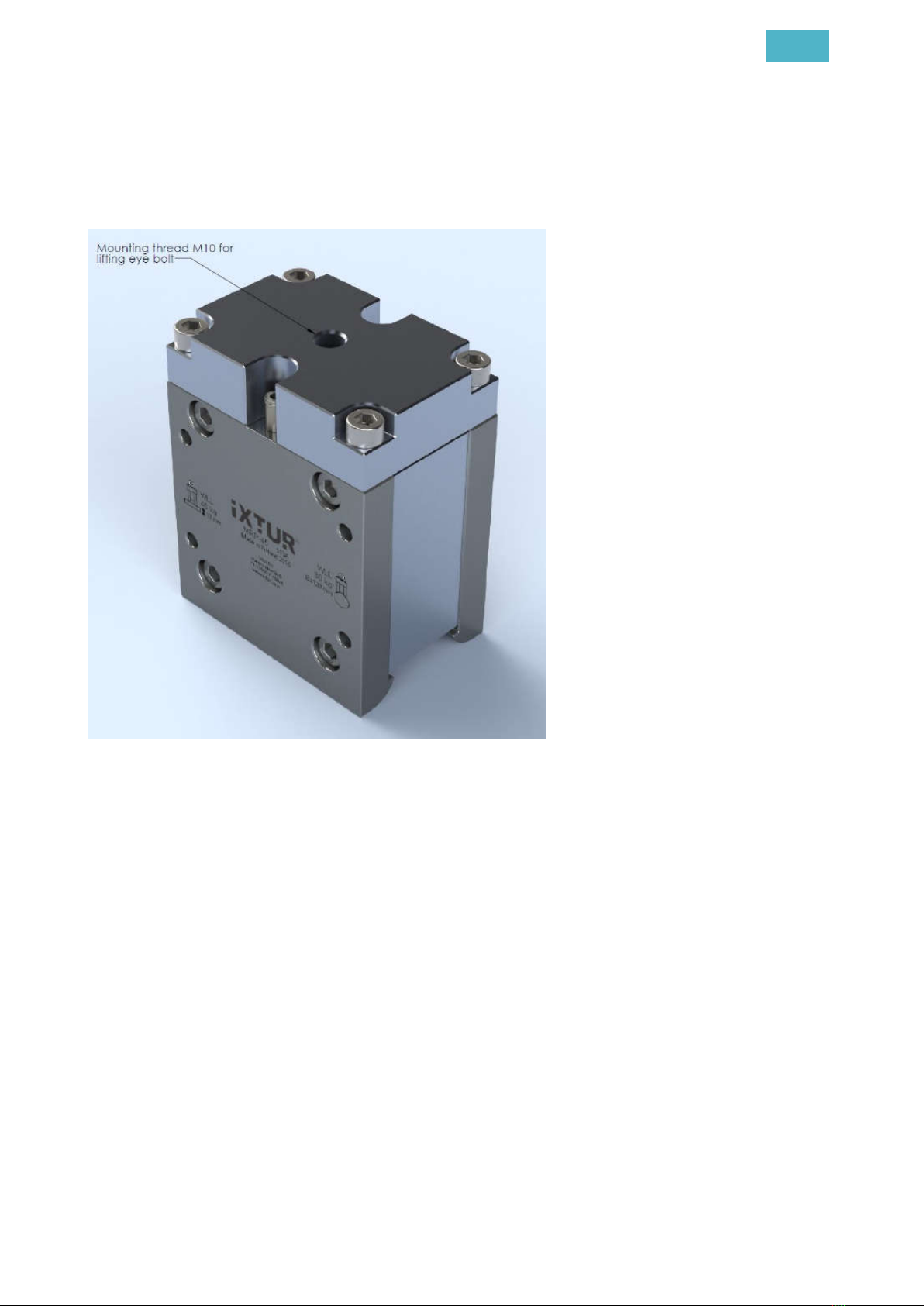

Ixtur Ltd / MRP-45

Technical Specifications

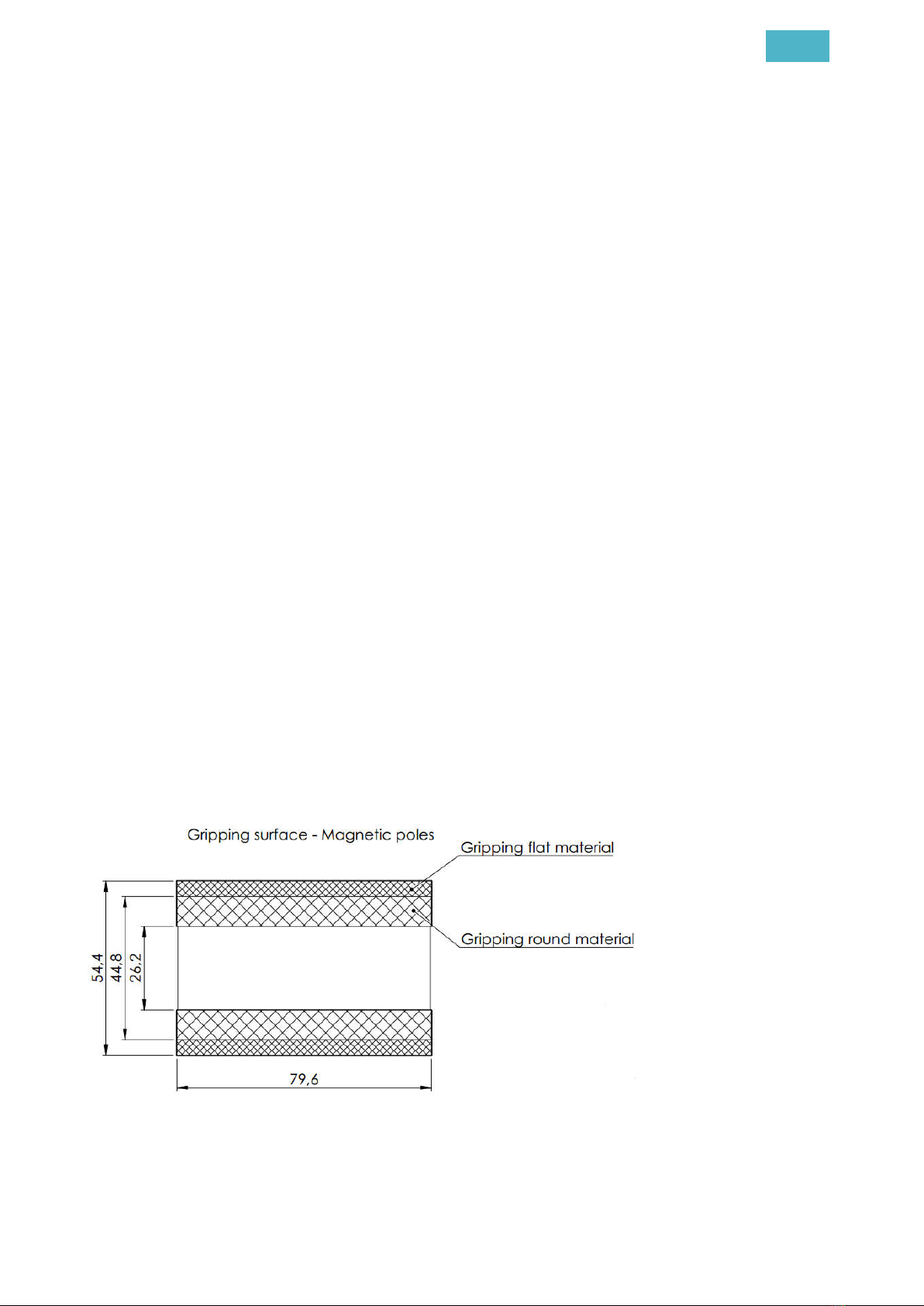

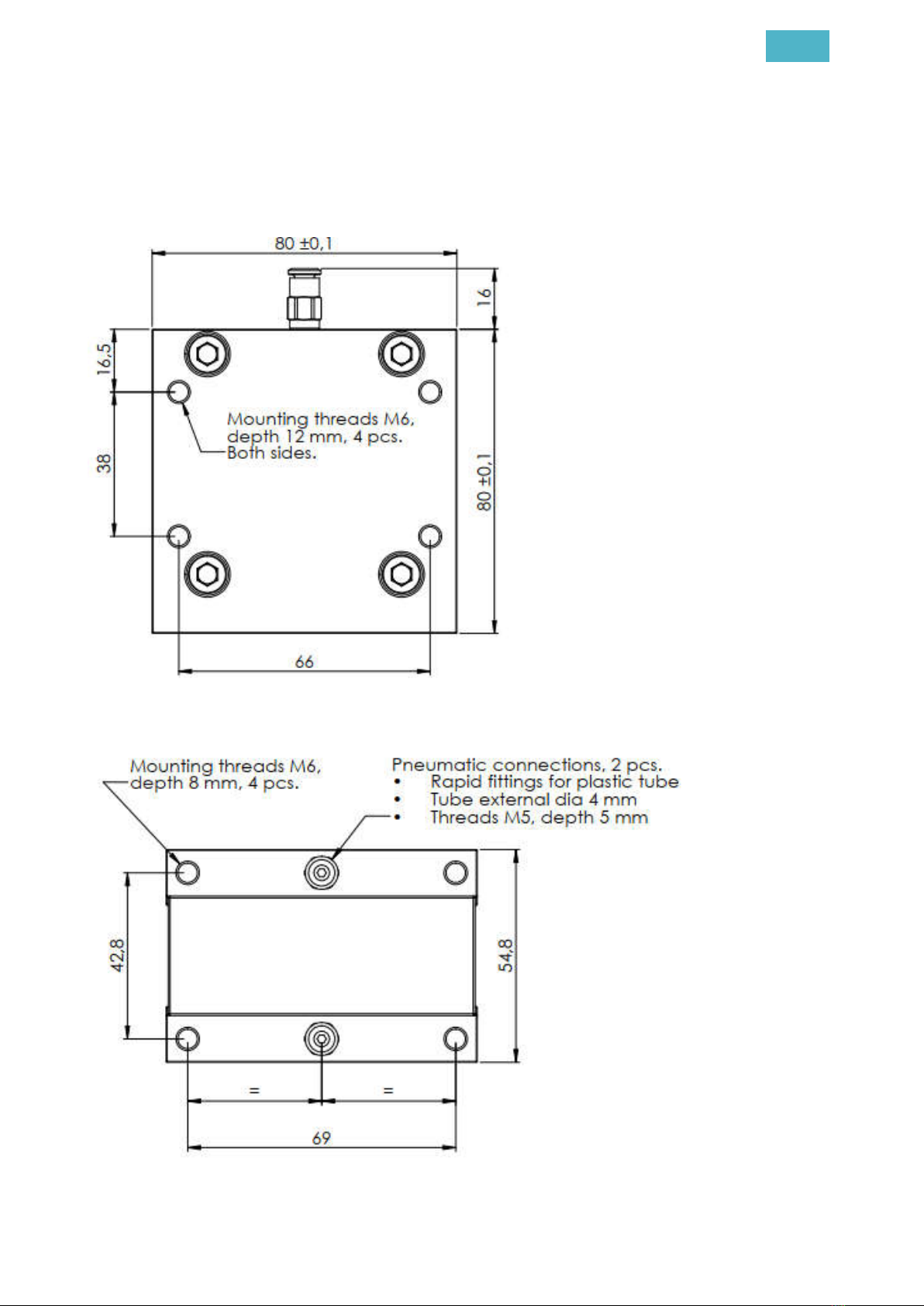

Dimensions:

- Length: 80.0 mm

- Width 54.8 mm

- Height: 80.0 mm (height with lifting adapter 100.0 mm)

- Weight: 1790 g (weight with lifting adapter 2000 g)

Capacity:

- Rated holding force: 1324 N (S355 S ≥ 12 mm plate)

- Rated holding force: 883 N (S355 cylinder ø ≥ 120 mm)

- Rated lifting capacity for plate with safety factor 3: 45 kg (S355 S ≥ 12 mm)

- Rated lifting capacity for solid round object with safety factor 3: 30 kg (ø ≥ 120 mm)

- Residual holding force flat: maximum 1200 g

- Residual holding force for other shapes:

MRP-45’s magnetic structure (similar to standard lever magnets) makes residual grip-

ping capacity sensitive to material and geometry of the lifted part. In extreme case, a

part up to 4 kg may stay connected to the magnet. This may happen just after the mag-

net has been turned OFF. When this behavior is critical to the application, the actual

parts need to be pretested with the MRP-45 magnet.

Environmental conditions:

- Operating temperature: 0 °C … +50 °C

- Storage temperature: -20 °C … +50 °C

- Humidity 0 % … 90 %

- IP67 (The device is protected from dust and temporary immersion up to 1 m)

Requirements for compressed air:

- Recommended pressure: 6.0 bar

- Functional range: 5.0 … 8.0 bar

- Water separation

- Particle filter ≤ 5µm

Information related to medical implants

- Safety distance for a person with active implanted device is 50 cm of air or other non-

magnetic material. The distance is measured from the magnet or magnetic material

attached to it.

o Maximum static magnetic field of MRP-45 is 200 mT on the gripping surface.

o Interference with active implanted devices, e.g. cardiac pacemakers – Action level for expo-

sure to static magnetic fields is 0,5 mT [Directive 2013/35/EC].