10

User Guide | Apollo Kit

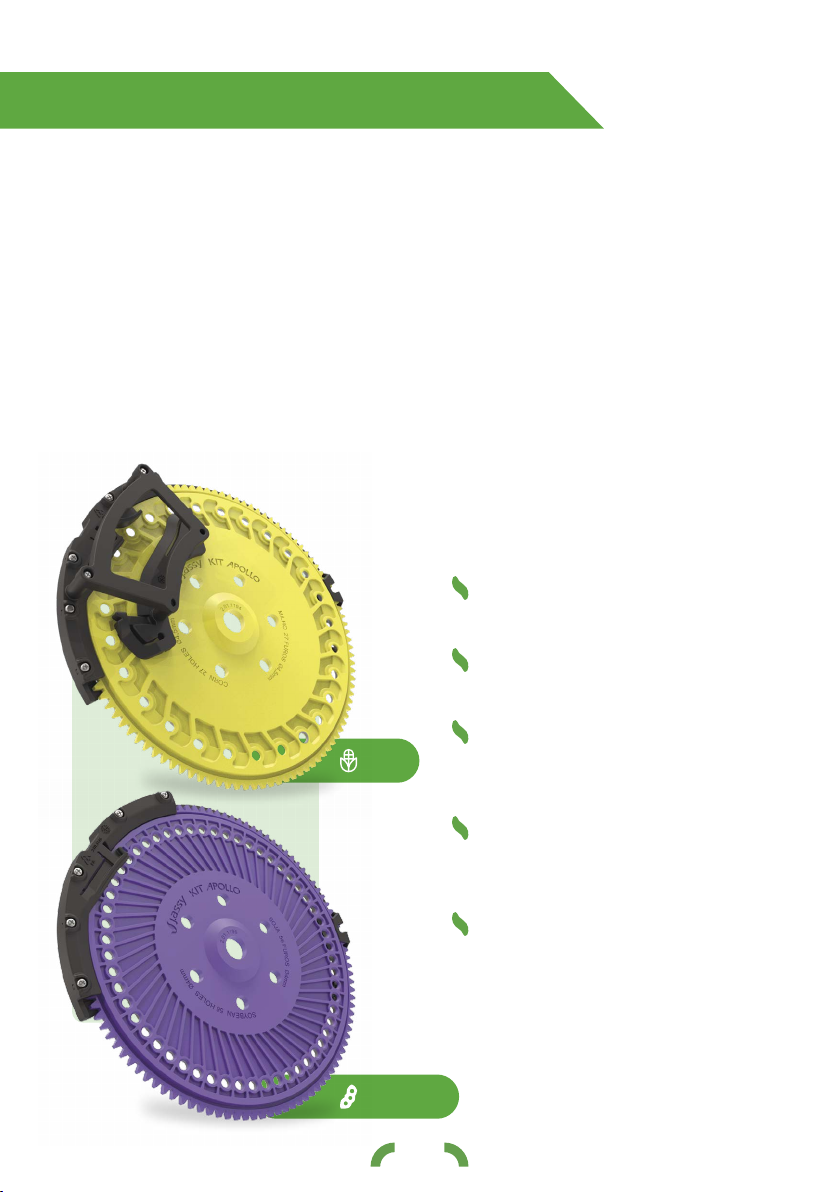

End-of-Life Signs

The Kit Apollo will begin to show signs of wear after several years of

use. The kit is designed to maintain optimum performance even after

the rst signs of wear appear.

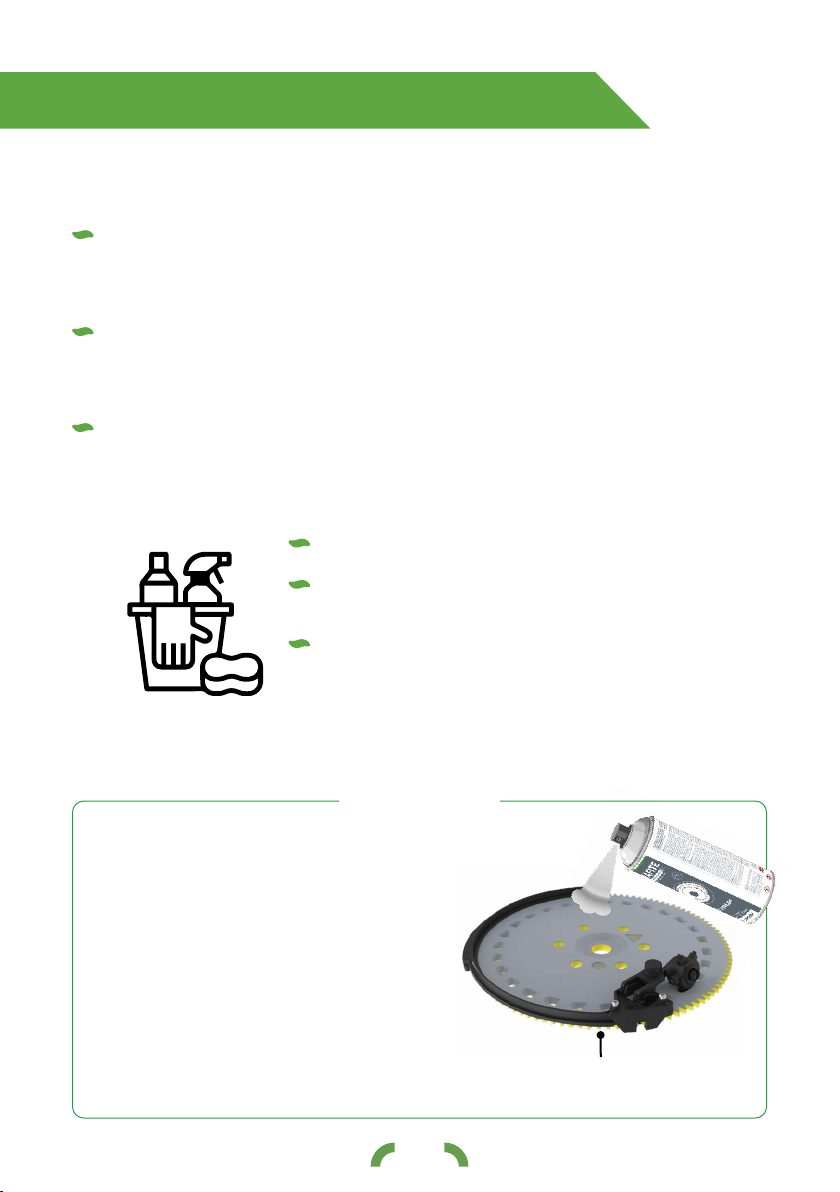

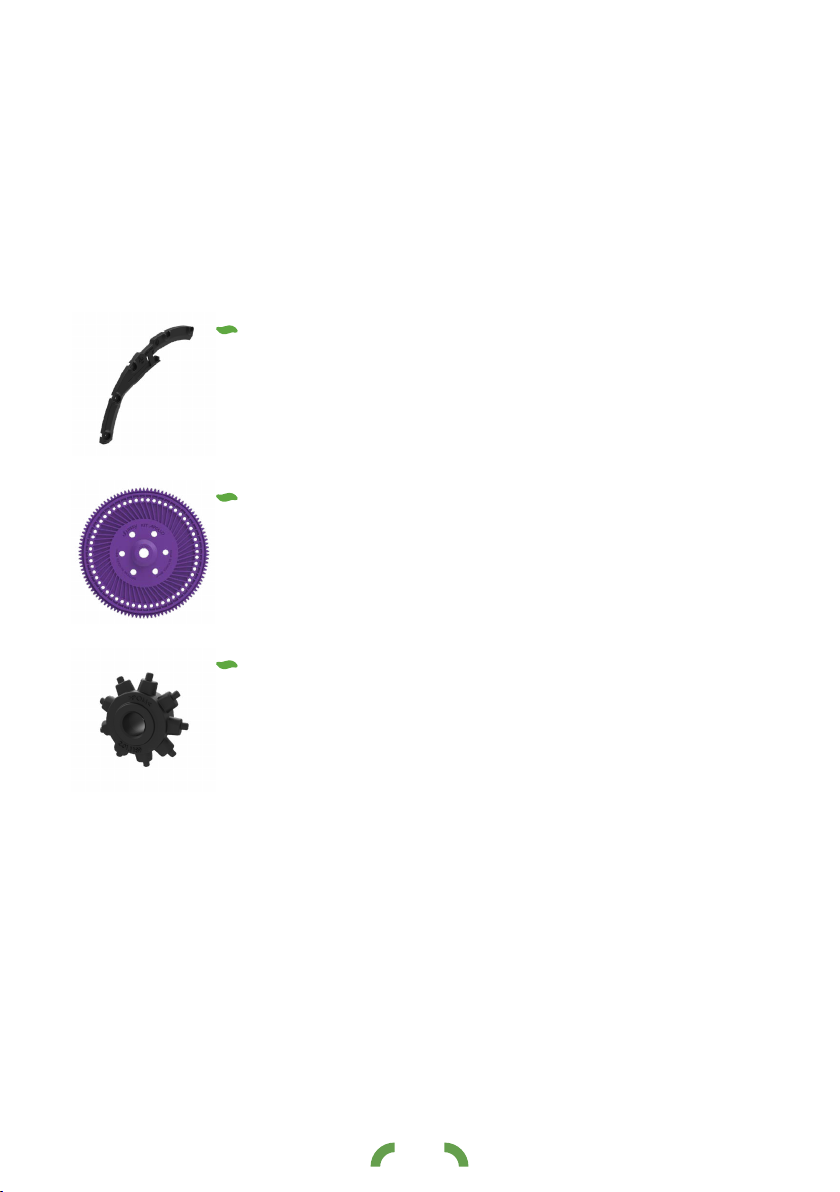

Upper pads: When the upper pad is subjected to

excessive wear, the kit’s singulation is affected,

resulting in an increased number of multiples or an

excessive number of skips. It is recommended that

the kit be replaced whenever a drop in singulation

performance occurs.

It is recommended that the following criteria be used to determine

whether it is time to replace a kit due to wear in its parts:

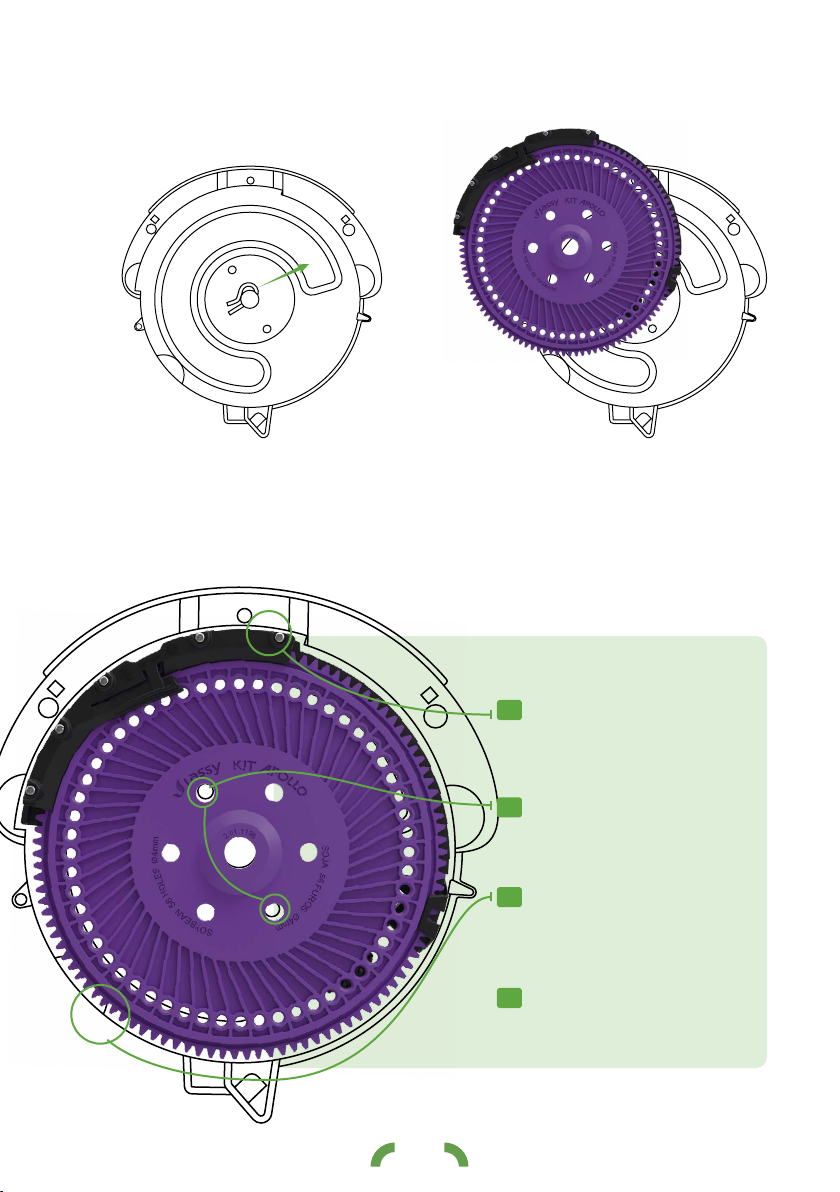

Metering disk: The contour of the disk holes may

present signs of wear over time and affect the

distribution of seeds in the soil. If seed distribution

has been greatly impaired and the disk holes are

visibly deformed, it is recommended that the kit be

replaced.

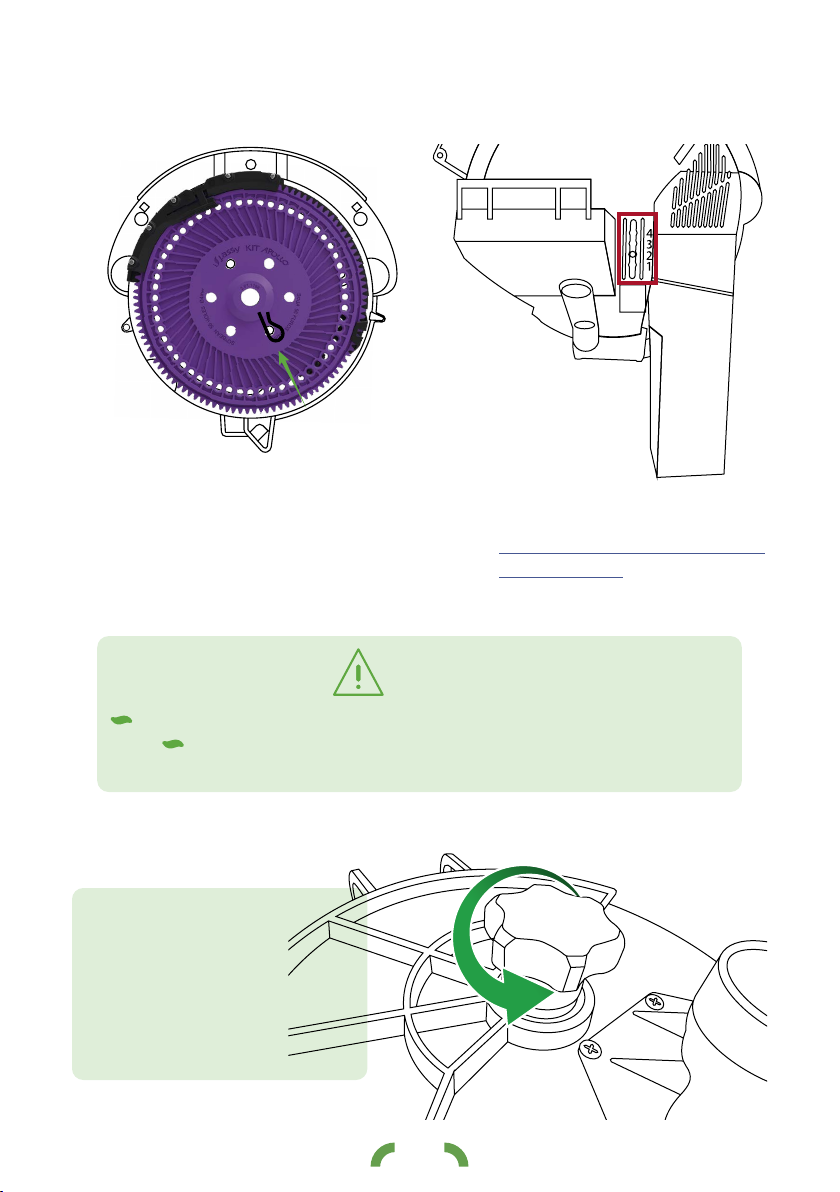

Ejector wheel: The ejector wheel’s teeth must be

capable of penetrating the disk holes in order to

remove any debris and ensure the holes are kept

clean. If any of the ejector wheel’s teeth are worn

to the point where they are no longer able to reach

through the disk holes, it is recommended that the

kit be replaced.