Table of Contents

Specications .......................................................... 04

Visum Monitor ........................................................ 04

Visum Fertilizer....................................................... 04

Installation................................................................ 05

Visum Monitor ........................................................ 05

Visum Fertilizer....................................................... 06

Recommendations ................................................. 07

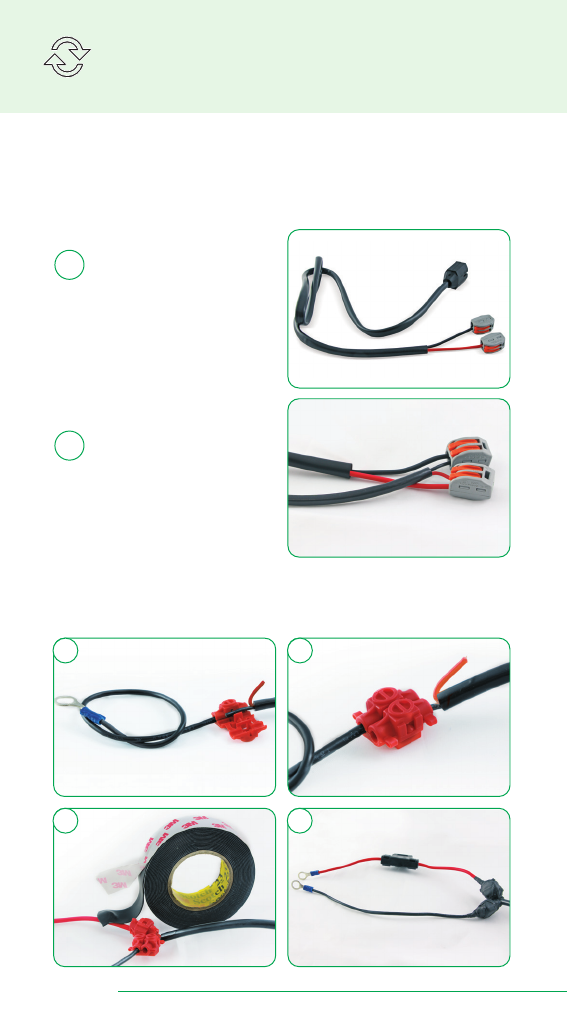

Power Connection................................................... 08

Connecting to a power plug inside of

the tractor cab........................................................ 08

Connecting to the tractor battery........................... 08

Attach the antenna................................................. 09

Network ID ............................................................... 10

Operation ................................................................. 12

Functions description ............................................. 14

F1 | Reading sensor status..................................... 14

F2 | Changing the monitor volume......................... 15

F3 | Changing the Screen Brightness..................... 15

F4 | Check sensor ID.............................................. 16

F5 | Address sensors.............................................. 17

F6 | Display the monitor ID..................................... 18

F7 | Customize the Maneuver beep time ............... 19

Troubleshooting table ............................................. 20

Cleaning and Storage.............................................. 22

Warranty ................................................................... 22

Discarding ................................................................ 23

100 Yellow | 25 Magenta 100 Black