J88 OWNER MANUAL 3

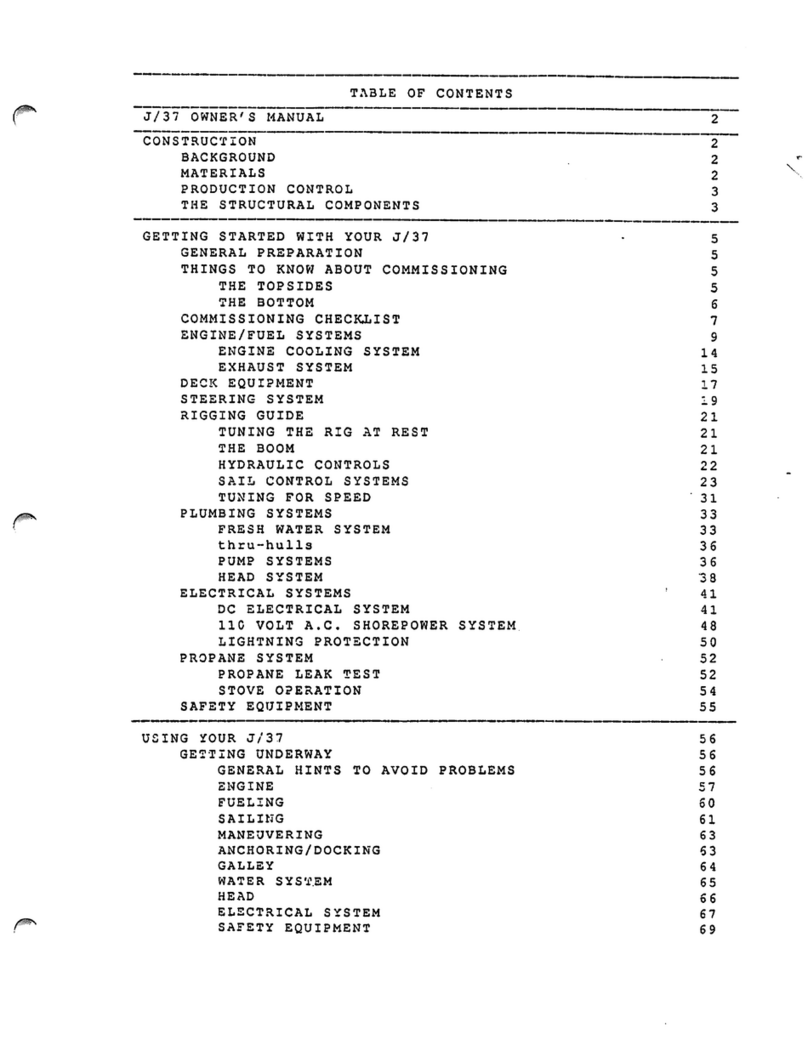

Table of Contents

Introduction...................................................................................................................................................................... 4

CE Certification ............................................................................................................................................................... 5

Specifications.................................................................................................................................................................. 8

Important Contacts......................................................................................................................................................... 9

Commissioning Checklist ...........................................................................................................................................14

Important Commissioning Follow-up........................................................................................................................ 15

Tuning the Rig ...............................................................................................................................................................16

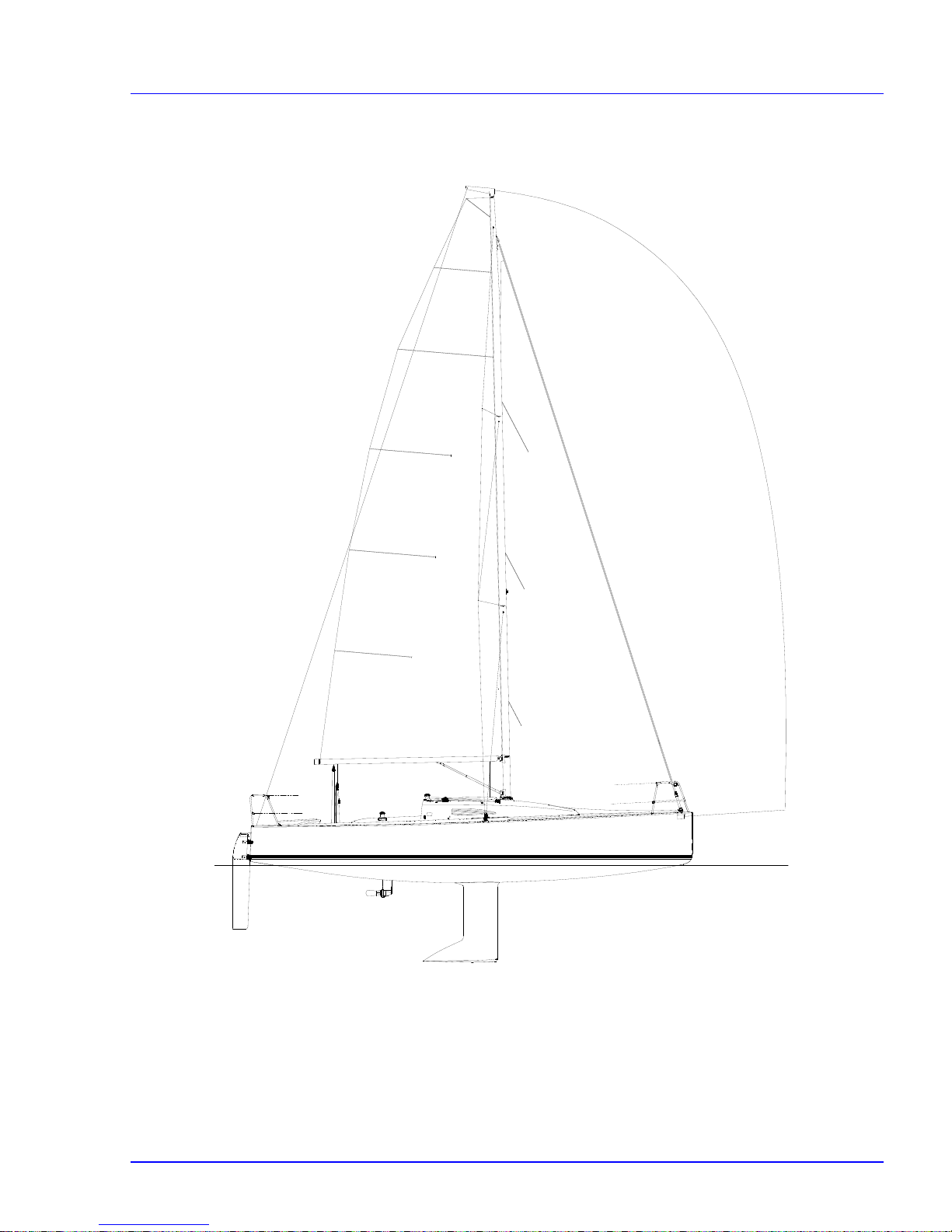

Diagrams, Layouts, & Schematics.............................................................................................................................18

Mainsheet Diagram.....................................................................................................................................................18

Traveler System Layout..............................................................................................................................................19

Adjustable Jib Lead System.......................................................................................................................................20

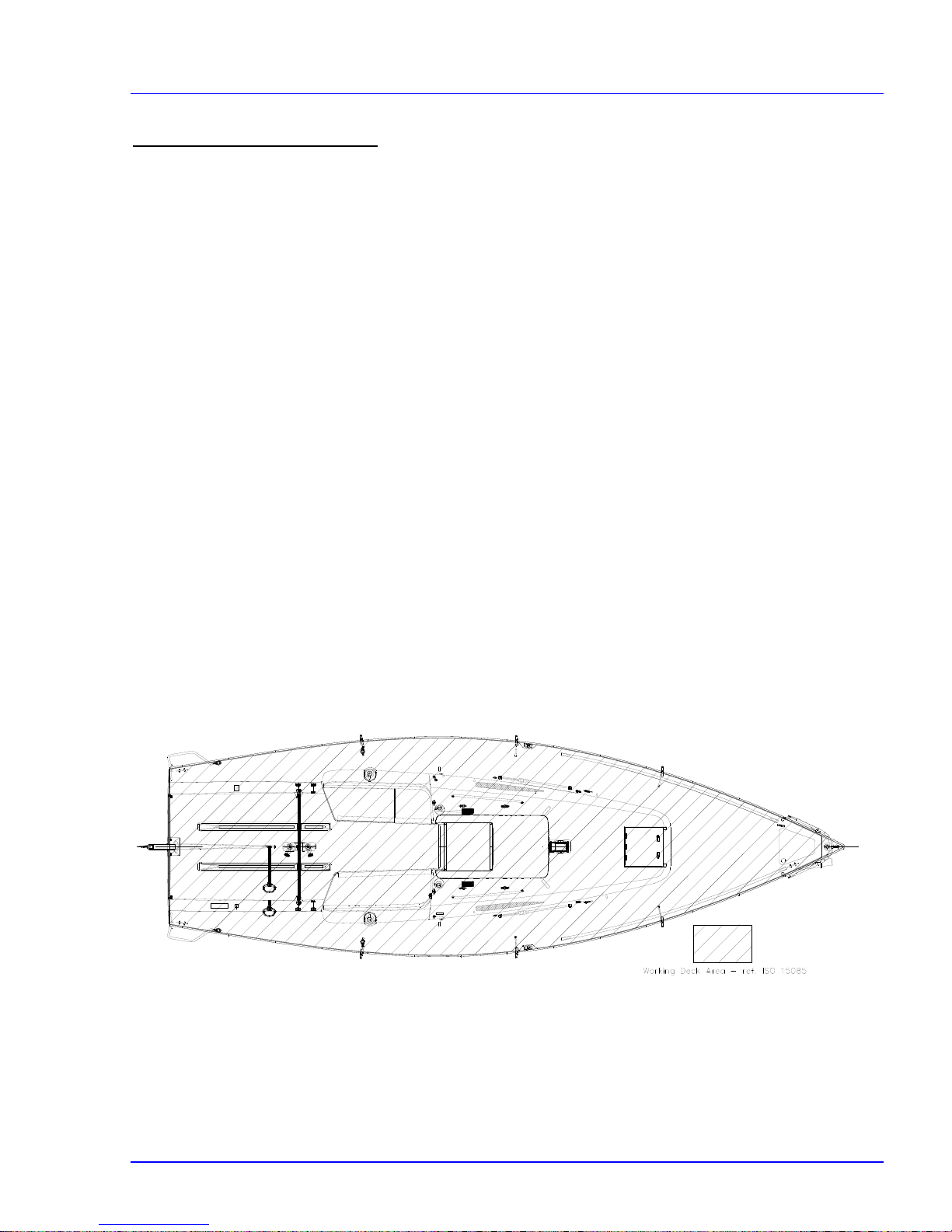

Cabin Top Layout........................................................................................................................................................21

Reefing System Layout...............................................................................................................................................22

Backstay System.........................................................................................................................................................23

Cunningham System ..................................................................................................................................................24

Spinnaker Sheet Blocks..............................................................................................................................................25

Engine Fueland Exhaust Layouts............................................................................................................................. 26

Bilge Pump Layout & Switch ......................................................................................................................................27

Thru-Hull & Seacock Locations..................................................................................................................................28

Head & Holding Tank Schematic................................................................................................................................ 29

DC Distribution Panel.................................................................................................................................................. 30

DC Component Layout ..............................................................................................................................................31

DC Battery Charging Schematic................................................................................................................................ 32

AC Optional Schematic & Panel ................................................................................................................................33

Bonding System .........................................................................................................................................................34

Engine System ..............................................................................................................................................................35

Sail Drive......................................................................................................................................................................35

Fuel System................................................................................................................................................................. 35

Engine Cooling & Exhaust Systems.......................................................................................................................... 35

Engine Safety Precautions.........................................................................................................................................36

Engine Start & Shutdown............................................................................................................................................37

Engine Maintenance...................................................................................................................................................38

Plumbing Systems........................................................................................................................................................39

Thru-Hulls & Seacocks...............................................................................................................................................39

Pump Systems............................................................................................................................................................ 39

Head System...............................................................................................................................................................39

Electrical System ..........................................................................................................................................................40

Optional 110V AC System............................................................................................................................................41

Safety..............................................................................................................................................................................43

Maintenance Tips & Checklist ....................................................................................................................................45

Storage Tips...................................................................................................................................................................48

APPENDIXA- Best Practices - Boat Inspection.......................................................................................................50

APPENDIX B -ABS(Dated) Guidelines for SurveyAfter Construction...................................................................55

APPENDIX C - Care and Cleaning Recommendations forAcrylic Portlight............................................................ 56

APPENDIX D - J/88 Supplier List...............................................................................................................................58

CCFC Limited Warranty.....................................................................See Warranty Package Included with the Yacht