J/145 OWNER GUIDE

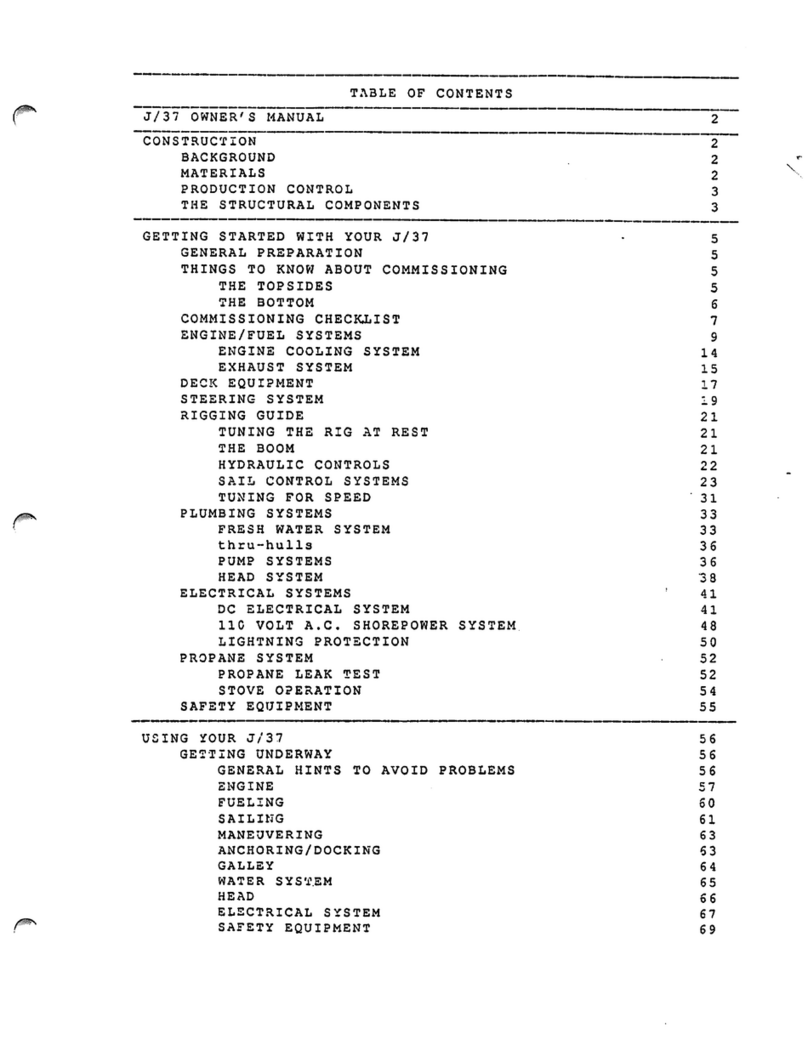

Introduction 2

Specifications....................................................................................................................................................................5

Important Contacts...........................................................................................................................................................6

Commissioning Checklist...............................................................................................................................................7

Getting Started With Your J/145.....................................................................................................................................8

Before Proceeding..........................................................................................................................................................8

J/145 Steering System....................................................................................................................................................9

Sail Control Systems.......................................................................................................................................................9

Diagrams, Layouts, & Schematics...............................................................................................................................12

Mainsheet & Traveler Diagram...................................................................................................................................12

Halyard Layout.............................................................................................................................................................13

Reefing System Diagram............................................................................................................................................14

Checkstay System.......................................................................................................................................................15

Jib & Genoa Hardware Layout....................................................................................................................................16

Deck Hardware Layout................................................................................................................................................17

Engine & Exhaust System Layout..............................................................................................................................18

Fuel System Layout.....................................................................................................................................................19

Thru-Hull Locations......................................................................................................................................................20

Fresh Water System Layout.......................................................................................................................................21

Head Sump Layout......................................................................................................................................................22

Bilge Pump Layout.......................................................................................................................................................23

Head Plumbing System...............................................................................................................................................24

Main AC/DC Distribution Panel...................................................................................................................................25

AC/DC Component Layout.........................................................................................................................................26

Standard Battery Wiring Schematic............................................................................................................................27

Optional Battery Upgrade Wiring Schematic.............................................................................................................28

DC Fan Layout.............................................................................................................................................................29

AC Layout with Forward Head Only...........................................................................................................................30

AC Layout with Aft Head Only ....................................................................................................................................31

AC Layout with Both Forward & Aft Heads................................................................................................................32

Optional Inverter Wiring...............................................................................................................................................33

Propane System Layout..............................................................................................................................................34

Bonding System...........................................................................................................................................................35

Rudder Shaft Detail .....................................................................................................................................................36

Keel Installation Instructions......................................................................................................................................367

Tuning The Rig................................................................................................................................................................38

Engine System ................................................................................................................................................................39

Sail Drive........................................................................................................................................................................39

Fuel System...................................................................................................................................................................39

Engine Cooling System................................................................................................................................................39

Exhaust System............................................................................................................................................................40

General Hints To Avoid Problems..............................................................................................................................40

Engine Safety Precautions...........................................................................................................................................41

Starting The Engine......................................................................................................................................................41

Turning Engine Off........................................................................................................................................................42

Fueling the Diesel Tanks..............................................................................................................................................42

Engine Maintenance.....................................................................................................................................................42

Plumbing Systems..........................................................................................................................................................43

General..........................................................................................................................................................................43

Fresh Water System.....................................................................................................................................................43

Thru-Hulls & Seacocks.................................................................................................................................................43

Pump Systems..............................................................................................................................................................43

Head System.................................................................................................................................................................44

Electrical System............................................................................................................................................................45

DC Electrical System....................................................................................................................................................45

110 VAC Shorepower System.....................................................................................................................................45