J D UltraSonics sonicom ATLAS Manual

sonicom™

J D UltraSonics

ULTRASONIC NOZZLES & AIR ATOMISERS

DUST SUPPRESSION - HUMIDIFICATION - ATOMISING - FOGGING

ATLAS ULTRA VIOLET

DISINFECTION UNIT

OPERATING AND MAINTENANCE

sonicom™

J D UltraSonics

GENERAL INFORMATION

An Ultra Violet Disinfection System is a versatile unit designed to kill waterborne bacteria using the proven

method of exposure to ultra violet light.

The unit is made from a tubular

quartz sleeve in which a UV lamp is inserted. Both components are housed in a

stainless steel outer chamber called a reactor. Water is disinfected as it passes through the reactor and is exposed

to a high intensive UV light that penetrates and deactivates bacterial cells.

The outer of bacteria and viruses differ in thickness and it is this thickness of skin which determines the amount of

UV light exposure to prevent their reproduction, rendering them dead.

UV systems should be installed with pre-filtration down to 5 micron. This prevents an effect called shadowing

where micro-organisms could hide behind particles in the water.

LOCATION

The steriliser should be mounted in a location

allowing sufficient room at the end of the unit to

withdraw the lamp and quartz sleeve. If this is not

possible use a flexible hose set allowing the chamber

to be unclipped from it’s mounting bracket(s) for

service and lamp change. Where possible the unit

should be installed to treat all the water as it enters

the system. If treated water is to be stored, the

storage tank should be fitted with a close fitting lid

and the overflow protected with a fly screen (Water

by-law 30). Tanks should only hold sufficient water for

a few hours use.

LAMP LIFE

The lamp will continue to emit sufficient ultra violet

for efficient operation of the unit for a period of

4,000 hours. The lamp must always be replaced at

this interval although a safer recommendation

usage period is one year or 2,000 hours. Failure to

change the lamp will result in insufficient UV

dosage for bacteria killing.

ELECTRICAL INSTALLATION

All metal components should be earth bonded.

Ensure the earth wire from the power supply is

connected to the earth point located at the one end

of the chamber. To avoid possible electric shock,

special care should be taken since water is present

near electrical equipment.

PLUMBING INSTALLATION

Although the chamber can be mounted at any

angle, the outlet connection should always be

uppermost to prevent airlocks in the chamber - the

ideal installation is vertical. Good quality pre

filtration is essential for correct operation. Replace

filters as required and always fit new elements,

never wash a dirty filter.

QUARTZ SLEEVE

The quartz sleeve should be checked and cleaned

periodically. When cleaning the quartz sleeve

ensure the unit is isolated from the electrical supply

and check the water supply is also turned off prior

to servicing.

www.jdultrasonics.co.uk | +44 (0)1924 378 448

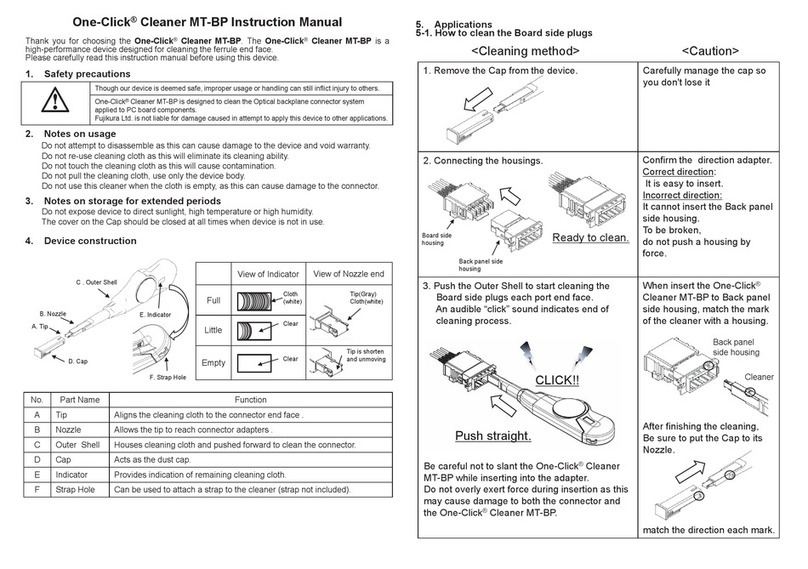

UV DISINFECTION - OPERATING & MAINTENANCE

Never operate the unit if the lamp is outside the chamber.

Never stare at the light source.

Exposure to ultra violet light can cause conjunctivitis and erythema.

1. Disconnect the main power supply and allow the unit to power down.

Remove the earthing screw from the small tab located at the top rim of the

reactor chamber.

2. Gently push down and twist the lamp connector a quarter turn anti-clockwise

and the bayonet fitting will release the lamp holder from the Gland Nut. The

lamp will lift due to the spring which is loosely located in the bottom of the

quartz sleeve.

Lift the lamp clear of the reactor chamber and quartz sleeve and remove the

lamp from the connector by holding the green ceramic end and gently pulling

the lamp clear.

3. Nip the rim of the quartz sleeve and ease it free from the reactor chamber by

carefully twisting and pulling until it releases from the spring clip at the bottom

of the chamber. If the sleeve appears to be clean, wash it in warm, soapy

water and replace it into the chamber taking care not to lose the spring and

o-ring.

4. When handling a new lamp, the use of cotton gloves is recommended.

Remove the lamp from its packaging and set aside the lamp key which can be

found on the top end of the lamp. Fit the new lamp into the connector by

holding the ceramic end and noting the keyed format which ensures correct

connection.

www.jdultrasonics.co.uk | +44 (0)1924 378 448

UV DISINFECTION - OPERATING & MAINTENANCE

OPERATING AND MAINTENANCE INSTRUCTIONS

Caution: Prior to performing any work on the disinfection system, always disconnect the power

supply first

To replace the lamp, it is not necessary to disconnect the system from the water supply, or to drain the water

from the reactor chamber. Lamp replacement is a quick and simple procedure requiring only standard hand

tools. The UV lamp must be replaced every 2000 hours of operation (approximately one year) in order to

ensure adequate disinfection.

The Atlas range of UV units are supplied with a ballast controller interface and features a user friendly colour

LCD display which provides meaningful user feedback messages, including remaining lamp life and total days

operation.

Each controller requires a lamp key to be inserted into the lower RHS of the unit and one is supplied with

each new lamp. It is important to change the key every time a new lamp is fitted as they are supplied as a

matched pair with information linked to each other.

1

2

sonicom™

J D UltraSonics

5. Insert the lamp back into the quartz sleeve until the spring resists further

travel. Gently push down and twist the lamp connector a quarter turn

clockwise - the bayonet fitting will hold the lamp holder in place.

6. Insert the lamp key into the ballast controller.

7. Reconnect the earth wire to the chamber tab.

www.jdultrasonics.co.uk | +44 (0)1924 378 448

UV DISINFECTION - OPERATING & MAINTENANCE

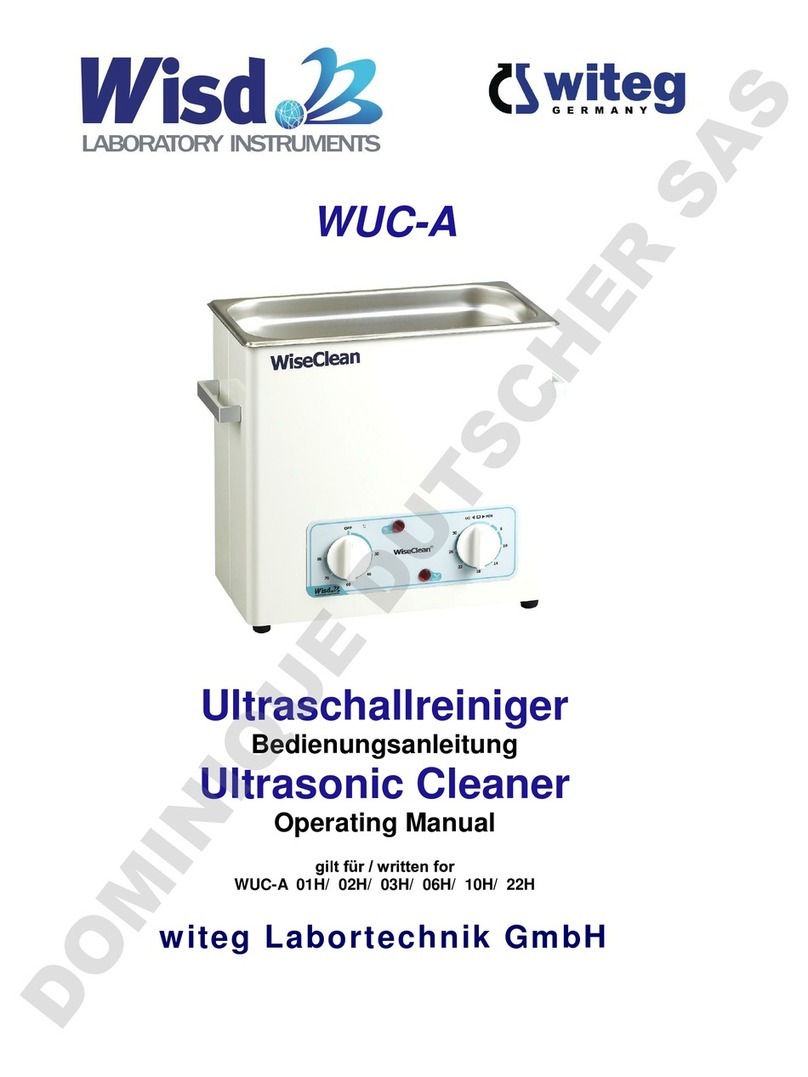

INITIATE LAMP COUNTDOWN SEQUENCE

After changing the lamp on the system, the controller

must be reset in order for the system to begin its

countdown function on a newly installed lamp. To

perform this reset, firmly depress the button on the

front of the controller and then manually power up the

unit.

Keep holding down the button for five seconds until the

controller has reset the internal timer. Release the

button and the lamp countdown feature has now been

reset. An audible chirp will be heard as well as the

“lamp life reset” screen.

Atlas UV

Atlas UV

Atlas UV

lamp life reset

continue holding

button to reset

lamp timer

5s

screens during reset

2

1

sonicom™

J D UltraSonics