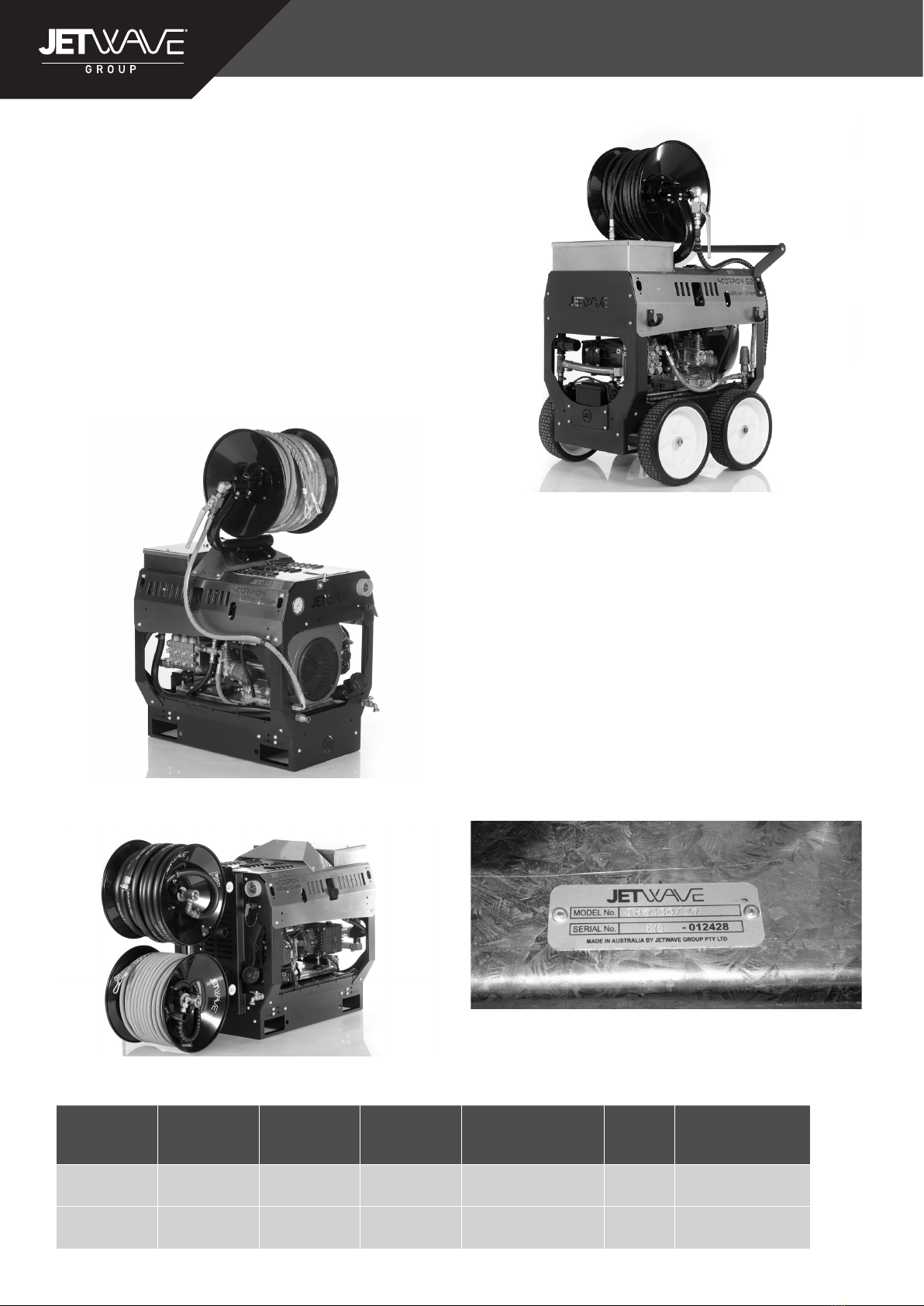

SCORPION G2 MANUAL - WATER JETTER/DRAIN CLEANER

4

clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may

affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained tools.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool, may become hazardous when used

on another tool.

Service

• Tool service must be performed only by qualied repair

personnel. Service or maintenance performed by

unqualied personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section

of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of

electrical shock or injury.

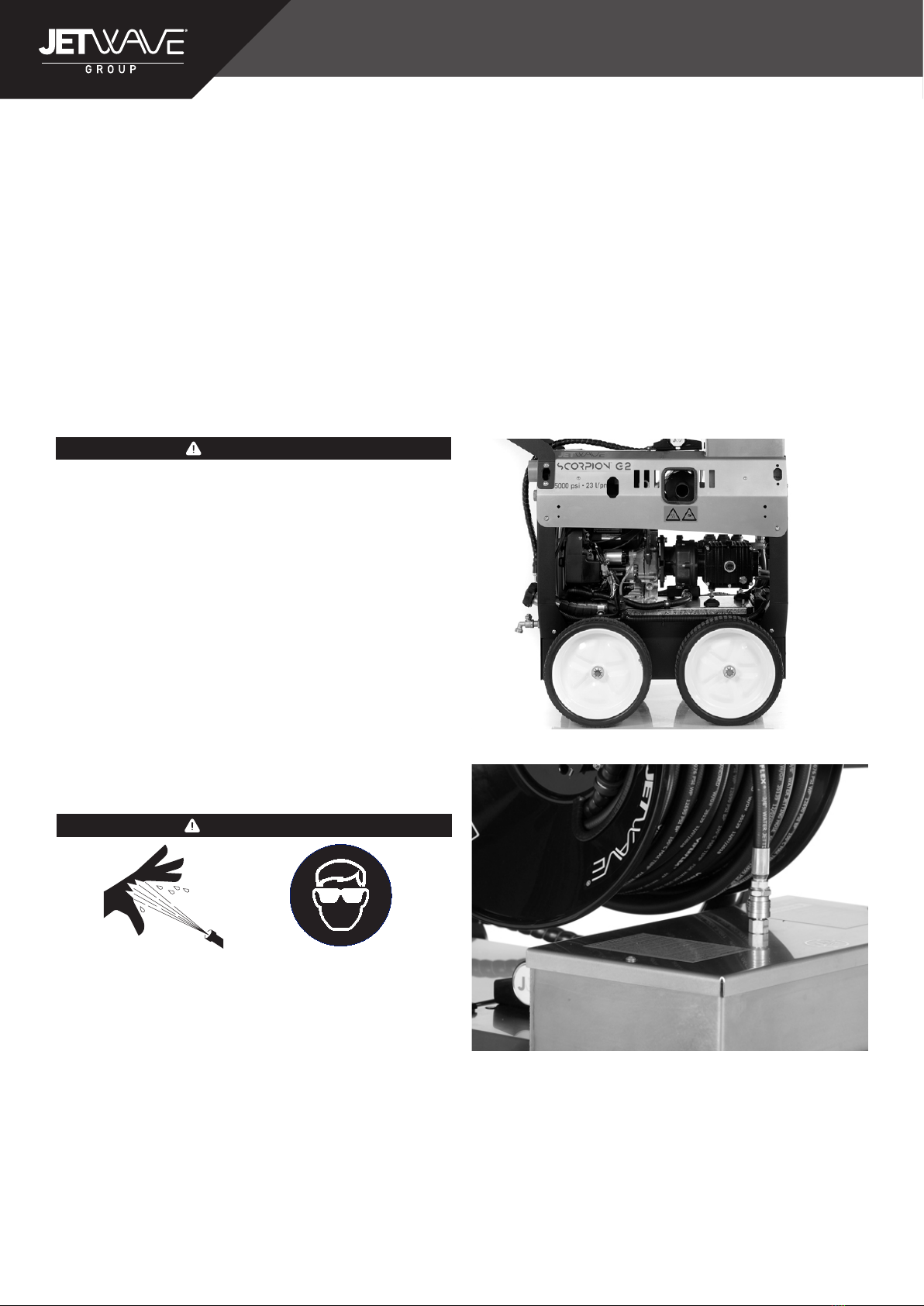

WATER JETTER SAFETY

WARNING

This section contains important safety information

that is specic to this tool.

Read these precautions carefully before using

this drain Cleaning Machine to re duce the risk of

electrical shock or other serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Keep this manual with machine for use by the operator.

• Never operate the jetter with the hose end outside of

the drain. Hose can whip, causing striking injuries and

spray can penetrate skin and cause serious injury.

• High pressure water can inject under skin resulting in

serious injury including amputation. Do not direct spray

at people or animals.

• Do not operate jetter above the 5080 psi pressure

rating or 60°C (inlet water temperature). This increases

the risk of injury, including burns, and damage to the

jetter.

• One person must control the jetting process and

water ow. If the jetter hose comes out of the drain,

the operator must be able to shut off the water ow

to reduce the risk of the jetter hose whipping, causing

striking and high pressure injection injuries.

• Always use appropriate personal protective equipment

while handling and using drain cleaning equipment.

Drain may contain chemicals, bacteria and other

substances that may be toxic, infectious, cause

burns or other issues. Appropriate personal protective

equipment (PPE) includes safety glasses and gloves,

and may also include equipment such as latex or

rubber gloves, face shields, goggles, protective

clothing, respirators, head protection, hearing

protection and steel toed footwear.

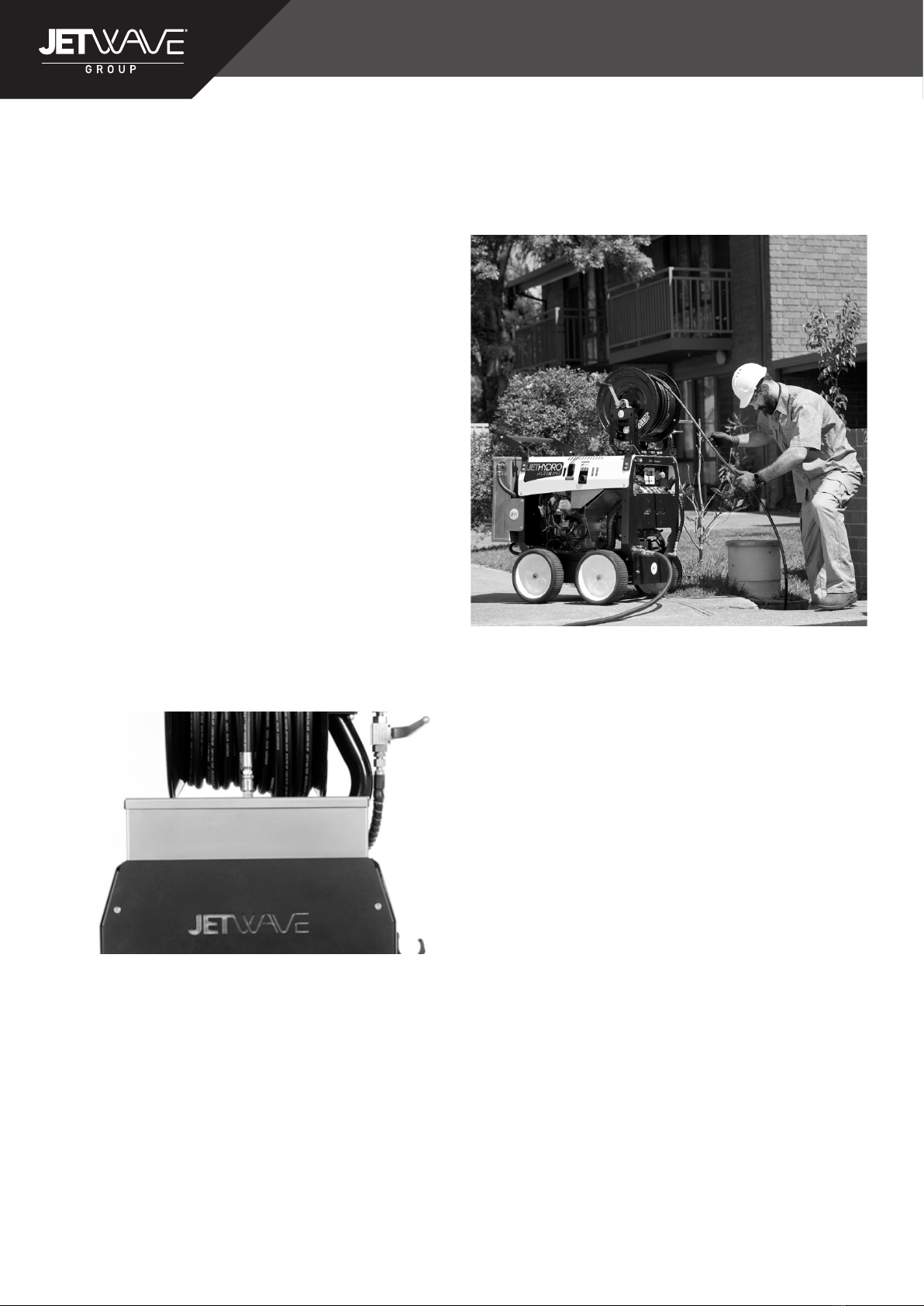

• Practice good hygiene. Use hot soapy water to wash

hands and other body parts exposed to drain contents

after handling or using drain cleaning equipment.

Do not eat or smoke while operating or handling

drain cleaning equipment. This will help prevent

contamination with toxic or infectious material.

• Do not spray toxic or ammable liquids. This will

reduce the risk of burns, re, explosion or other injury.

• Gasoline and its vapors are highly ammable and ex-

plosive. See engine manual for precautions to reduce

the risk of burns, explosions and serious injury while

handling and using gasoline.

• Engines produce carbon monoxide, a colorless,

odorless poison gas. Breathing carbon monoxide can

cause nausea, fainting or death. Do not start and run

engine in an enclosed area, even if doors and windows

are open. Only operate outside.

• Hot surfaces can cause burns and re. Keep body

parts and ammable material away from hot surfaces.

• Read and understand this manual, the engine manual

and the warnings and instructions for all equipment

and material being used with this tool before operat-

ing. Failure to follow all warnings and instructions may

result in property damage and/or serious injury.

• Follow all applicable workplace health and safety

regulations and guidelines concerning the use of this

equipment.

If you have any question concerning this Jetwave®product:

– Contact your local Jetwave®distributor.

– Visit jetwave.com.au/nd-a-dealer to nd your local

Jetwave contact point.