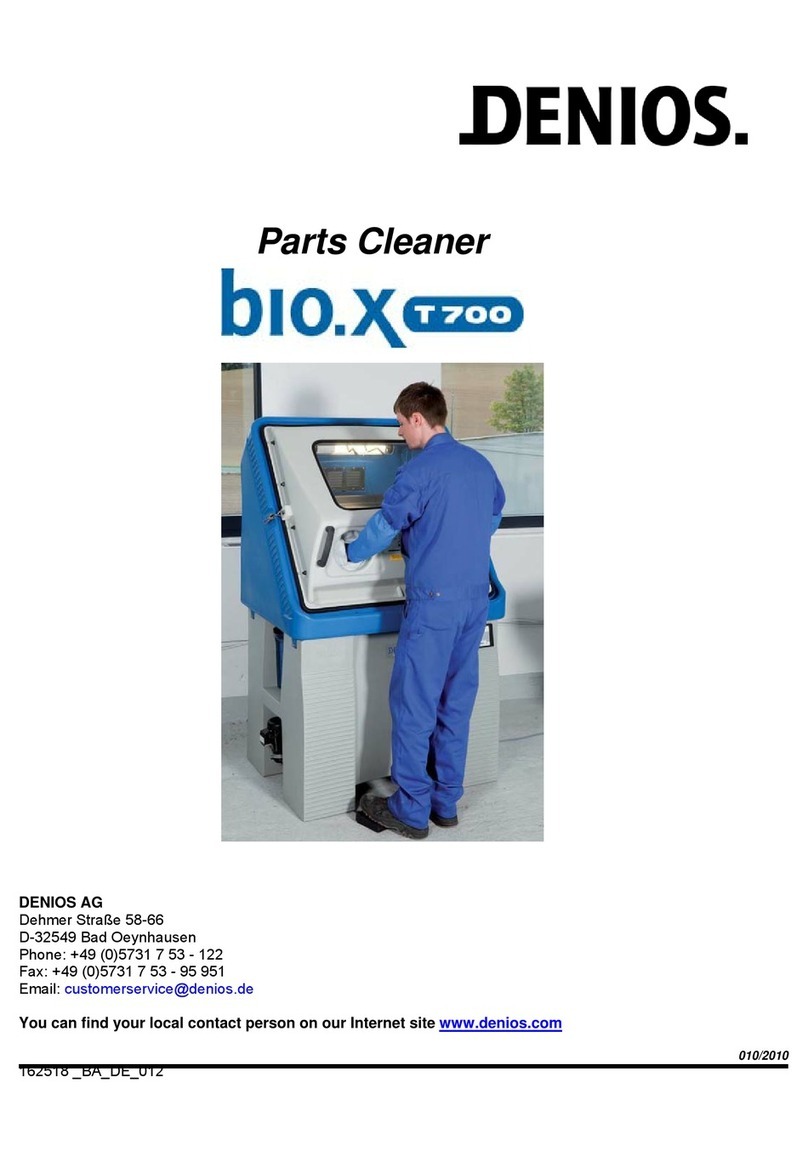

Denios L500 User manual

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Issued 05/2016

User manual

Safety Cleaner L500

DENIOS AG

Dehmer Str. 58-66

D-32549 Bad Oeynhausen

Phone.: +49 5731 753-0

Fax.: +49 5731 753-199

E-Mail: [email protected]

Please find your local contact person at www.denios.com

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Page 2 of 6 pages Issued 05/2016

Safety instructions1

This user manual applies to the solvent parts cleaner. It contains all the information needed regarding

correct start-up, trouble-free operation, maintenance, putting out of service and disposal. The hints and

instructions in these Operating Instructions must be carefully followed and observed.

If the intended use is strictly followed in accordance with the Operating Instructions, we accept liability

within the scope of terms of warranty.

No changes, extensions or modifications may be made to the product without the manufacturer's authori-

sation. No liability is accepted for changes made without the manufacturer's authorisation with the warranty

ceasing to be valid in such a case.

Comply with the requirements of the Water Management Act (WHG) as well as the applicable Land-

specific regulations (VAwS - regarding systems for handling water hazardous substances).

National regulations and safety regulations must be observed.

If you have any further questions, please contact us on our service hotline on 0800 - 753-000-2.

This unit can only be used safely if you have read these Operating Instructions carefully and

strictly. Follow the instructions it contains. These Operating Instructions are an integral part of this

unit and must be available to the personnel who operate the unit at all times.

The staff must be instructed about these Operating Instructions and particular attention has to be

paid to prohibitions and hazard warnings.

The electrical system has to be designed in accordance with VDE 01000. For safety reasons the

equipment must only be operated, if a Residual Current protective Device (RCD) with a release

current of 30 mA is connected upstream.

This must be checked by a qualified electrician.

In accordance with the German BGV A3, electrical equipment has to be inspected regularly.

The device must be placed on a plane, stable and suitable surface.

Detergents containing highly flammable substances must not be used. Only use detergents ap-

proved for the use with this unit.

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Page 3 of 6 pages Issued 05/2016

Technical Data2

Design according to BGR 180

Dimensions (W x D x H)

1010 x 785 x 1220 mm

Work surface height

870 mm

Load capacity

250 kg

Net weight

55 kg

Tank

Material PE LD, double walled design, optional discharge unit possible,

inclined bottom

Maximum fill capacity

100 l

Table top

can be hinged to the side with arresting device

Usable work surface

925 x 510 mm

Pump, flow rate

approx. 4 l/min

Hose system

Three-way shut-off cock and hose with cleaning brush

Control unit

Foot switch with automatic reset

El. connection

230V / 50Hz with a 3 m-cable and two-pin grounded plug

Filter

350 µm optional

Noise pressure level

< 70 dB(A)

Dimensionel

sketch

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Page 4 of 6 pages Issued 05/2016

Produktbeschreibung3

The solvent parts cleaner serves for efficient cleaning of workpieces polluted with oil and grease using

solvent-based cleaning agents (cold cleaners). In connection with a collecting sump, the parts cleaner

complies with all requirements of the Water Management Act.

The unit consists of a sump, table top and cover.

A pump, switched via a 230 V –foot switch, pumps the cleaning fluid to the three-way shut-off cock and

further to the cleaning brush.

Only such solvents may be used

-to which PE LD is resistant and that are not decomposed by PE LD

-whose ignition point is > 55 °C

-whose mass portion of halogen organic substances is more than 1%.

Commissioning4

After removing the packaging, check the unit housing and controls for any possible damage caused in

transit. If such damage is found, do not connect the unit to the mains. Report damage immediately to the

carrier who delivered the unit and to DENIOS AG at the service number indicated above. The original

packaging should be kept.

Place the unit in a dry, stable location as required.

The floor must be plane. If necessary, level out any uneven surfaces with suitable shimming material.

Filling in of cleaning fluid4.1

Fold the table top open from the side and fix it using the attached support rod.

Pour 100 l of cleaning fluid into the tank.

Electrical connection4.2

The unit is connected to the customer's mains supply system via the power cable and plug.

Pay attention to correct mains voltage: The voltage of the power source has to comply with the details on

type plate of the unit.

Caution: The mains supply must be fitted with a residual-current protective device (RCD) in compliance

with DIN VDE 0100! (See section 2)

Connect the unit to the mains.

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Page 5 of 6 pages Issued 05/2016

Operation5

Place the parts to be cleaned in the cleaning basin of the parts cleaner.

Do not exceed the maximum load of 250 kg!

Depending on the setting of the 3-way shut-off cock, parts can be cleaned by:

-rinsing them using the flexible hose and nozzle

-using the brush with detergent running through

Note: In the middle position, both outlets are opened.

The pump is switched on by pressing the foot switch and the cleaning fluid flows then from the tank to the

cleaning hoses. The dirty cleaning fluid runs back into the tank via the middle outlet.

Servicing6

Caution! Before starting work on the cleaning table, switch off the electrical system and un-

plug the unit! Make sure that the device is disconnected!

Filling level6.1

Check the fill level against the markings on the tank wall regularly and refill lost fluid caused by evaporation

and removal. If the minimum filling level should be below 60 litres (lowest marking line), refill cleaning fluid.

Only fill in the same type of fluid that is already in the tank.

Cleaning fluid6.2

The cleaning fluid has to be replaced if

-there is a significant reduction of cleaning performance

-when checking the fill level and notable sediment deposits are detected on the bottom of the tank

After you have discharged the used cleaning fluid, remove any sedimentary residues from inside the tank

and (if existing) clean the filter.

Please follow the same process when inserting the new fluid as for the initial operation.

Disposal Instructions7

Cleaning fluid

Dispose used cleaning fluid observing the applicable national regulations. The applicable waste code

number can be found in the European Waste Catalogue.

Appliance

According to the directive on used electrical and electronic devices, owners of used appliances

are legally required to separately dispose of electrical devices that are not longer usable.

Please help to protect the environment by not disposing of worn out appliances with household

waste.

Original

User manual

186082_BA_SafetyCleaner L500_005_EN

Page 6 of 6 pages Issued 05/2016

Declaration of Conformity8

EC Declaration of Conformity

We hereby declare that the Safety Cleaner L 500 complies with the following directives:

EC Directives

2006/42/EC

2004/108/EC

Harmonised standards applied

EN 349

EN 12100 -1,-2

E 60204-1

EN 12981-1;-2.

DENIOS AG, 23.05.2016

..............................................

B. Boucke

Person responsible for documentation -Executive board-

Mr. Dipl.-Ing. A. Schulz

Table of contents

Other Denios Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

Bissell

Bissell STAINPRO 6 user manual

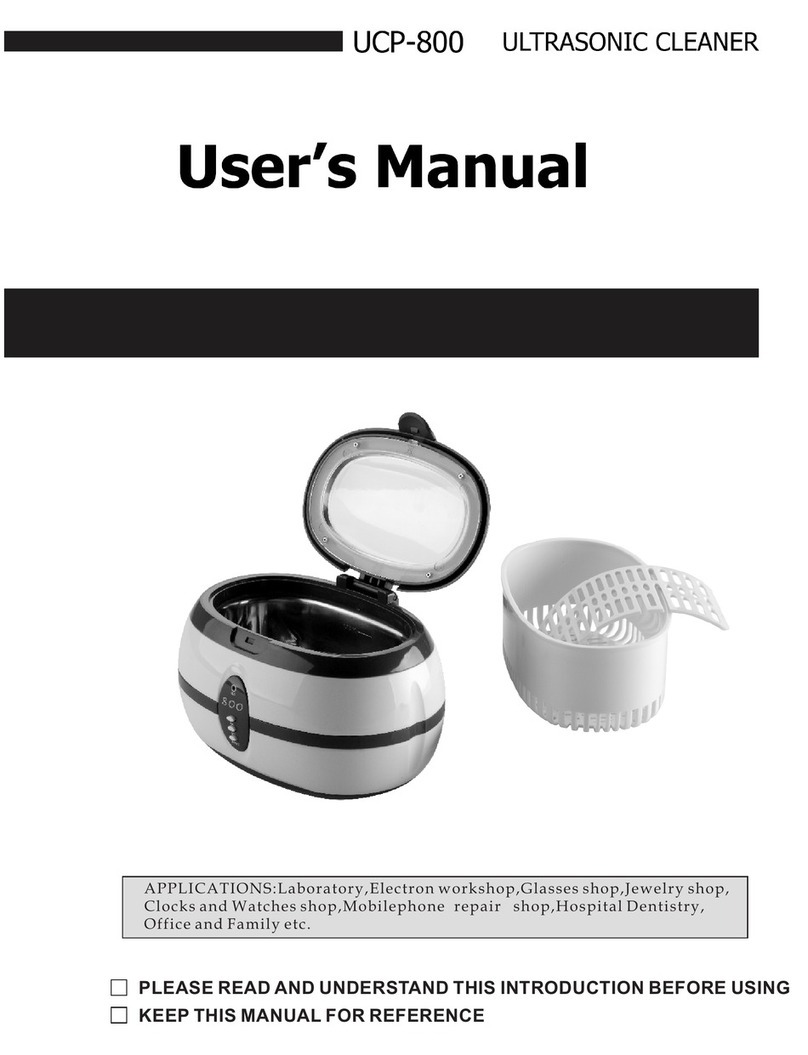

luxvision

luxvision UCP-800 user manual

ECOVACS

ECOVACS WINBOT 930 instruction manual

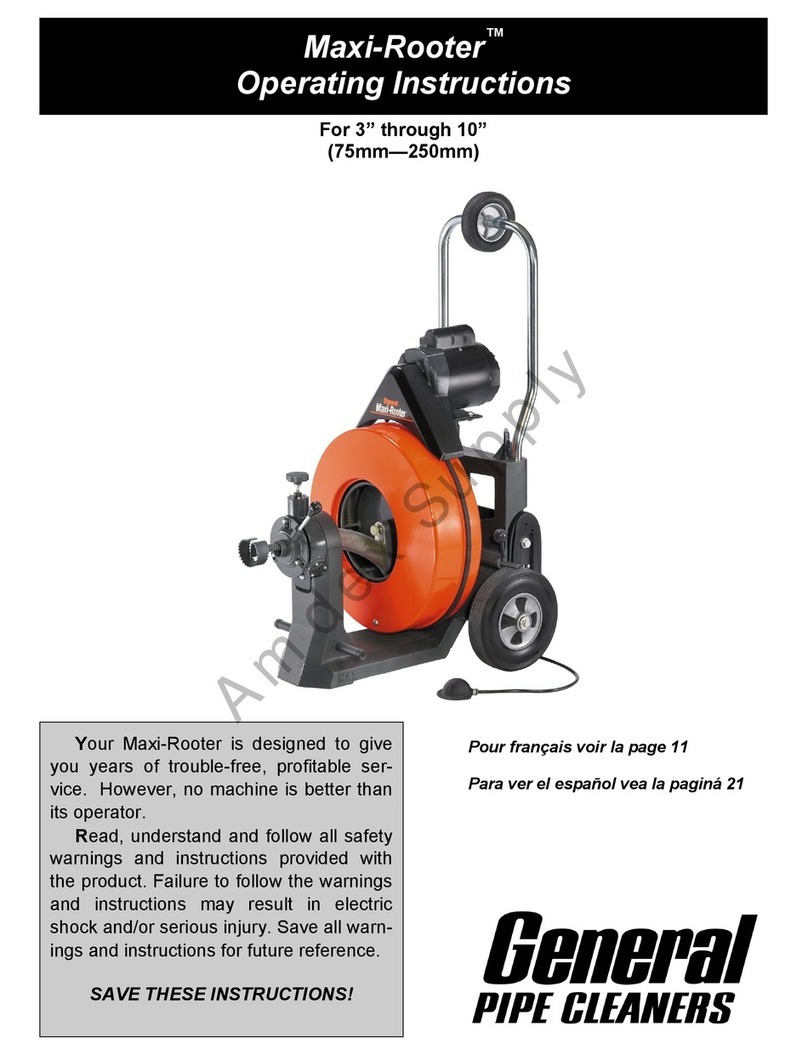

General Pipe Cleaners

General Pipe Cleaners Maxi-Rooter operating instructions

General Pipe Cleaners

General Pipe Cleaners Sewerooter T-3 operating instructions

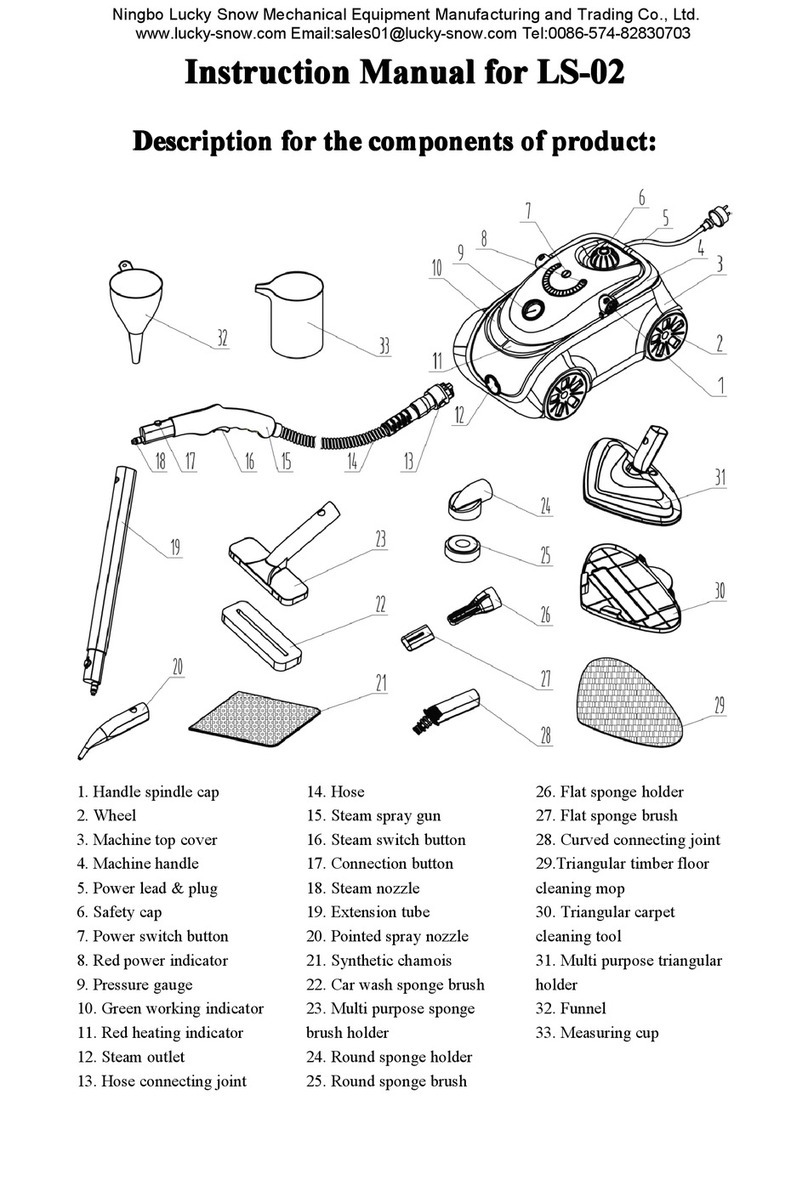

Lucky Snow

Lucky Snow LS-02 instruction manual

Orbegozo

Orbegozo LV 3450 instruction manual

Nilfisk-Advance

Nilfisk-Advance Roof Cleaner Instructions for use

Patriot

Patriot PW 110 Instruction manual for use and maintenance

SEVERIN

SEVERIN SC 7141 quick start guide

Clatronic

Clatronic MC 3240 Instruction manual & guarantee

Blaupunkt

Blaupunkt BPK-VCBB1XW instruction manual