Page 5

3. Operation

1. Prepare the meat by removing excess fat and trimming the meat. Check to make sure that

there are no bones in the product to be tenderized.

2. Place the product on the cutting board.

3. Slide the board forward so that the front edge of the product is beneath the blades.

4. Pull the handle down and the blades will penetrate into the meat.

5. Release pressure on the handle and it will go back to the top position.

6. Advance the board approximately 3" so that the next area of the product is beneath the

blades.

7. Repeat procedures 4-6 until the whole piece of meat is completely tenderized.

Note: To completely tenderize a product that is more than 3" thick, tenderize one side, flip it over,

and tenderize the other side.

4. Cleaning

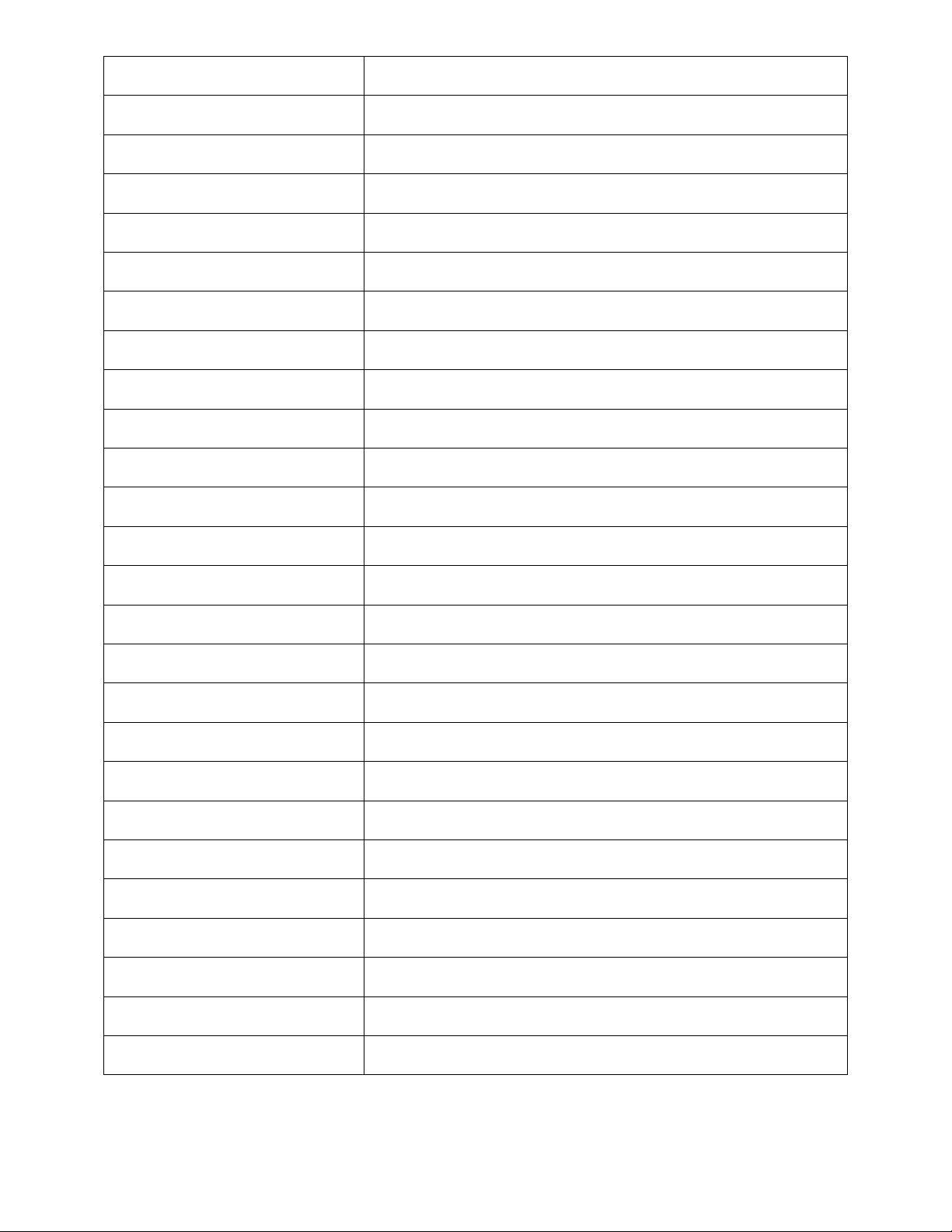

4.1. Disassembly for cleaning

1) Remove 3 knurled nuts (#11AE) located on the rear of the stripper frame assembly (#3-13-15H).

2) Remove hold-down plate (#22H).

3) Remove 2 knurled nuts (11AE), located on the front corners of the stripper frame assembly

(3-13-15H).

4) Lift stripper frame bar and remove the bar with the separators and holders.

5) To remove the blade set, use protective gloves or a towel to hold the blade set.

6) Loosen the knurled nuts (#11AE) that hold the dovetail bar (#11H). It is not necessary to

completely remove the knurled nuts, just loosen them enough to remove the blade set.

7) Remove the cutting board and wash it with soap and water in the sink.

8) Rinse the blade set, separator and holders with water to remove any pieces of meat. Then wash

them in a dishwasher.

9) Use small s/s brush provided to clean channeled separators.

10) The main body of the machine can be cleaned with soap and rinsed with water.

11) To assemble machine, reverse disassembly steps 1-7.

5. Maintenance

1) Check blade set for damage - light bends in the blades can be straightened using long nose

pliers. If the blades cannot be repaired, cut the damaged blade off with side cutters.

2) Check the channeled separators (41AE) for damage.

3) Check the stripper frame columns (13HN) to make sure they are securely fastened in the

stripper frame (3-HN).

•If necessary, apply thread locker (Loctite) to the threads on the stripper frame column

(13HN) and tighten with a 17mm or adjustable wrench.

4) Check stripper frame adjustment by measuring the distance between the top of the stripper

frame (3-HN) and the bottom of the boat assembly (2-44-17-43-55H). The distance measured on

both sides of the stripper frame columns (13HN) should be 3 1/8” (3.125”).

•If adjustment is necessary, remove shoulder bolts (116E) and jamming ring bolts (23N).

This will release the safety lockers (58-59H). Turn the adjustable screw nut assembly (21-

22AE) either clockwise to raise the stripper frame (3-HN) or counter-clockwise to lower

the stripper frame (3-HN).

•When adjustment is correct, install safety lockers (58-59H) with shoulder bolts (116E) and

jamming ring bolts (23N).

5) Check that the main column assemblies (9-51-31-32-56H) do not move.

•If column assemblies (9-51-31-32-56H) are loose, apply thread locker (Loctite) and

tighten bolts (31AH) located under the base (1H) with a 22mm or adjustable wrench.