IMPORTANT INFORMATION TO THE USER

ON THE USE

- Never switch on the machine without supply of water or solution.

- The machine must not be running for more than 5 minutes with the

gun in closed position to prevent pump overheat. (Machine with trigger)

- In switching off the machine, pull the gun trigger to discharge the

pressure remaining in the system. (Machine with trigger)

- Do not pull the machine by the hose or the electric cable.

- Alwaysuseshoeswithsolemadeofrubberorotherinsulatingmaterial.

- Ifthetemperatureis below0ºC, thewaterinthepumpcanfreeze, and

this can break the head. Therefore, in low temperatures, drain all water from the

pump.

- Neverpointthethehighpressurejettowardspersonsoranimals.Itcan

injure them.

- Never point the gun towards electric equipment.

- Never point the gun towards any thin surface.

- Do not allow children and untrained persons to use this machine and

keep them away from the area being cleaned.

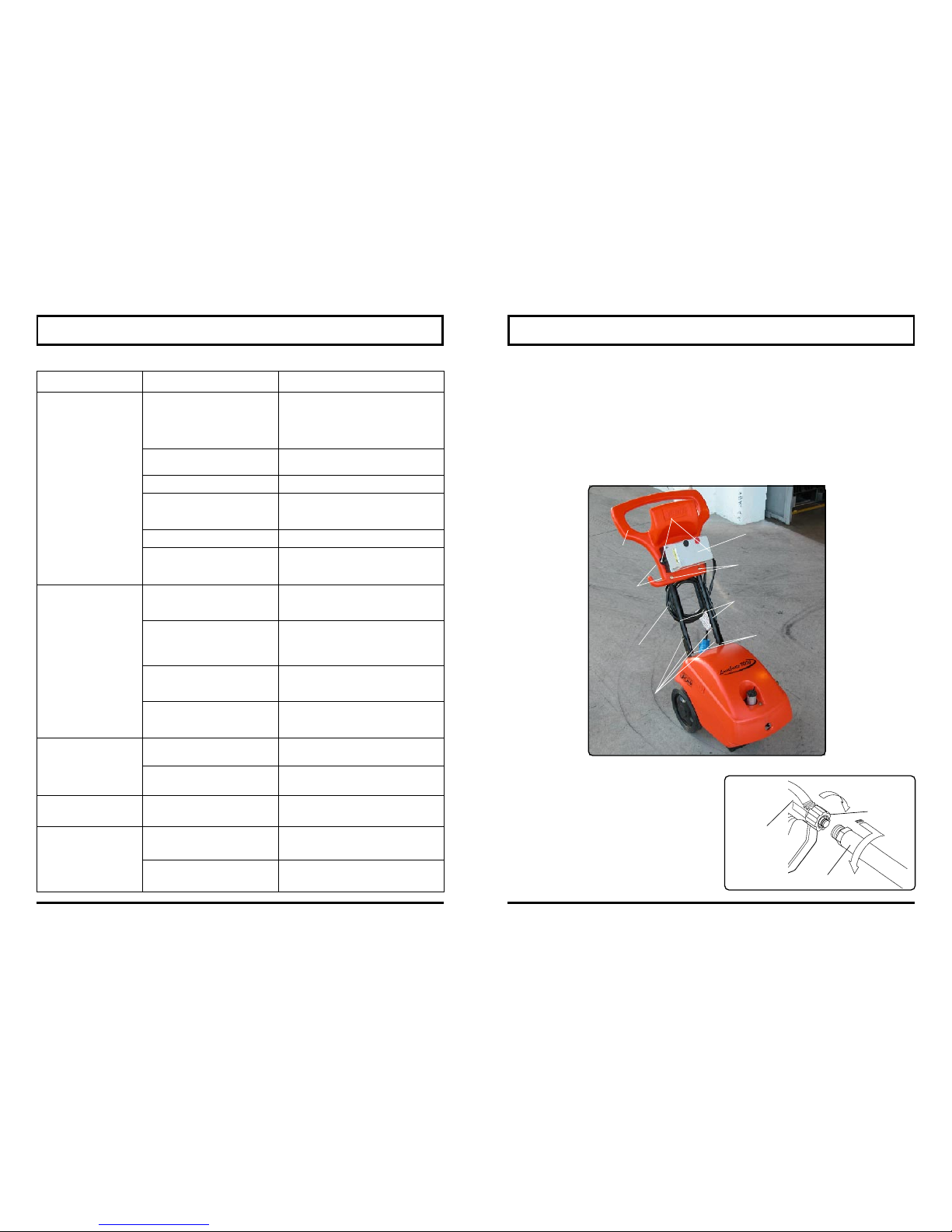

- After using the machine, use the safety button on the gun to lock the

trigger and prevent accidental pulling. (Machines with trigger)

- Be careful when using this machine close to flammable substances,

since a single spark can cause fire.

- Always disconnect the machine from the power supply circuit and

discharge the pressure from the system before servicing the machine.

ATTENTION: NEVER POINT THE JET TOWARDS ELECTRIC

EQUIPMENT OR THE POWER SUPPLY CIRCUIT.

NEVER USE TOXIC OR FLAMMABLE SUBSTANCES.

06 23

STATEMENT OF LIMITED WARRANTY

MÁQUINAS AGRÍCOLAS JACTO S.A. - JACTO CLEANING warrants this

machine and agrees to repair and replace parts and components which, under

normal operation and wear, following the technical recommendations, show

DEFECTSIN MATERIALORWORKMANSHIP:

WARRANTYPERIOD:

- One (1) year from the sale date to the dealer's customers.

WARRANTYAPPLICATION:

Jactooritsauthorizedrepresentativeshallhonorthiswarranty,ifanypart

or component shows confirmed defect in workmanship.

ITSHALLBEUNDERSTOODTHATTHEREPLACEMENT OFCOMPLE-

TE COMPONENTS, SUCH AS THE EQUIPMENT ITSELF OR THE GUN, SHALL

ONLY BE EXECUTED IN CASE THE DEFECT CANNOT BE REPAIRED BY

REPLACINGPARTS OFSUCHCOMPONENTS.

THIS WARRANTY SHALL BE NULL AND VOID IF:

- Installation is not made in accordance with the instructions of the operator's manual;

- Equipment is not used in accordance with the technical recommendations in the

OPERATOR'SMANUALandIDENTIFICATIONPLATE;

- Theequipmenthassignsindicatinguseofwrenchesorforceinthepressureadjustment.

- Accessoriesnotrecommendedbythemanufacturer are used;

- Repairsareperformedbyunauthorizedpeople;

- Unoriginalparts partsareused;

- Defectshave resulted from lackof lubrication, cleaning orfilter at the wateror additive

suction inlet;

- IdentificationPlate is changed,damaged or lost;

- Misuseorfailuretofollowthemanufacturer'srecommendations;

- Damagesresultedfromactionofregionalnaturalagents.(Forinstance,breakofthehead

due to water freezing in its inside, caused by low temperatures.);