03/23/05 J600CHT Assembly – DRAFT Prepared for Jacto

Service Seminar 3/2005

DRAFT COPY

Final Assembly and Setup Tips

1) Install the side step to the holes located on the left lower portion of the frame

using the three bolts supplied.

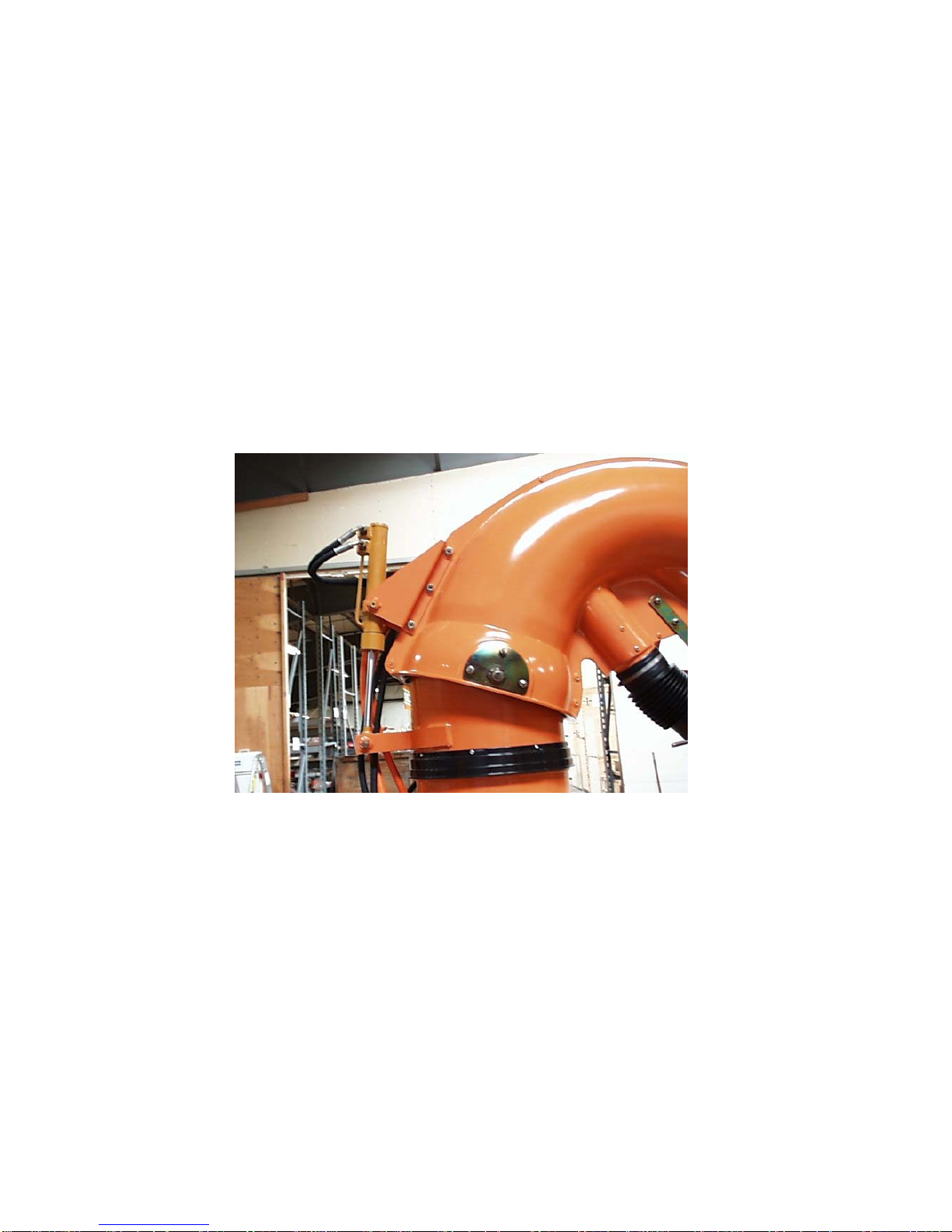

2) Install the center piece for the fan cage for the fan disconnect and crimp the end

onto the fan cage to keep the center piece from coming loose.

3) Perform final inspection of hose clamps, fittings and fasteners to make sure they

are tightened properly. Also check oil level in gear box.

4) Attach sprayer to the tractor’s three point hitch. DO NOT attach PTO shaft to

tractor’s PTO drive until the PTO shaft has been cut to the proper length. To

determine the proper length required for the tractor being used the operator must lift

the sprayer until the shortest distance between the sprayer’s drive shaft and the

tractor’s PTO drive shaft is obtained. The PTO shaft should have 1 ¼ inch of free

play at this point. Measure the PTO shaft and cut both ends equally to achieve the

free play indicated above.

5) Add water to tank. Prime pump by removing the cap on the three way valve,

located toward the bottom of the sprayer, and turn the valve handle to allow water to

flow for 1 second to bleed out any air. Return the valve back to the operating

position.

6) Make sure fan disconnect is engaged before spraying. NEVER attempt to engage

or disengage fan disconnect when fan is turning.

7) Engage PTO shaft with tractor RPM at low speed and then raise RPM until you

reach 540 RPM at PTO.