Hatchery Disinfectant Manual

3

Contents

Introduction .........................................................................................................................................5

General .............................................................................................................................................5

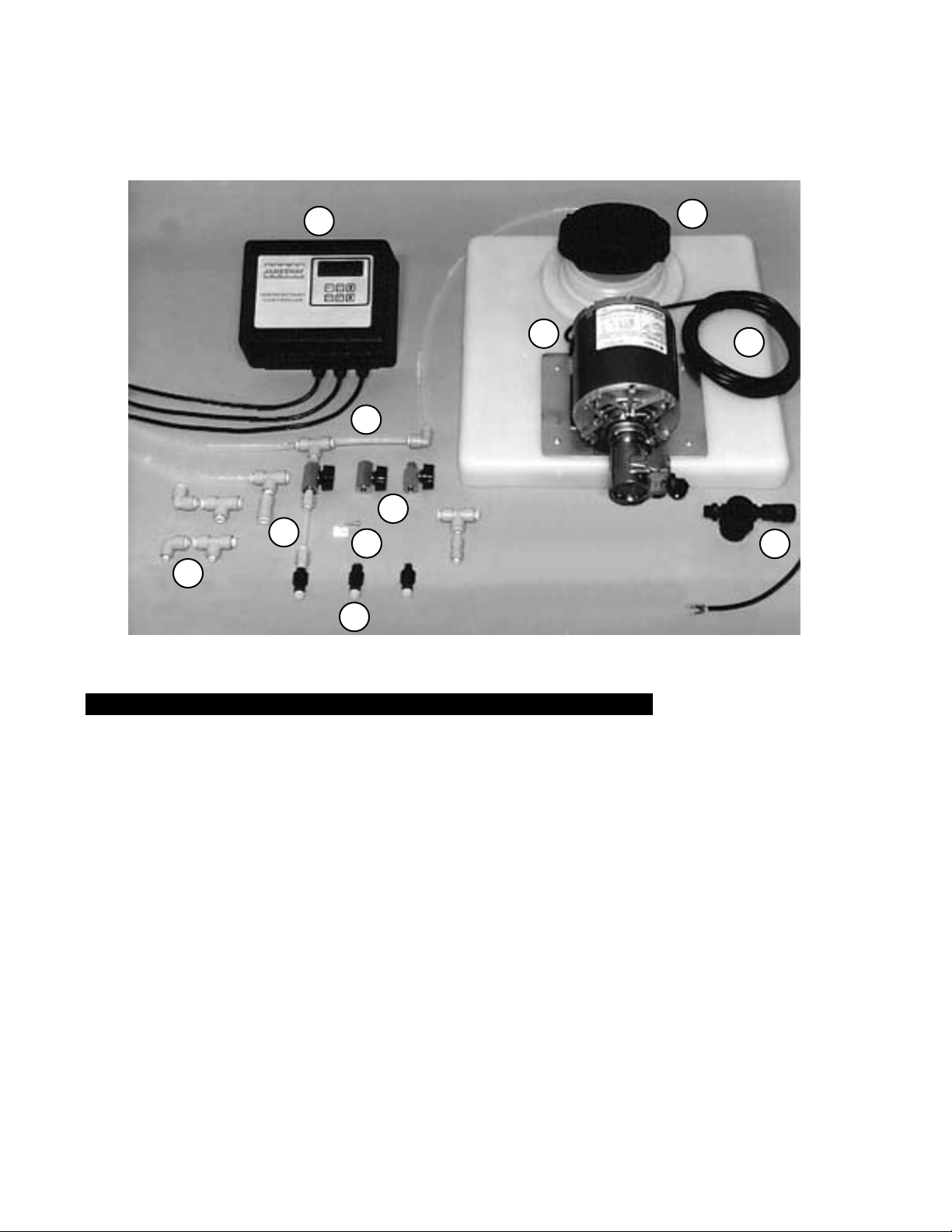

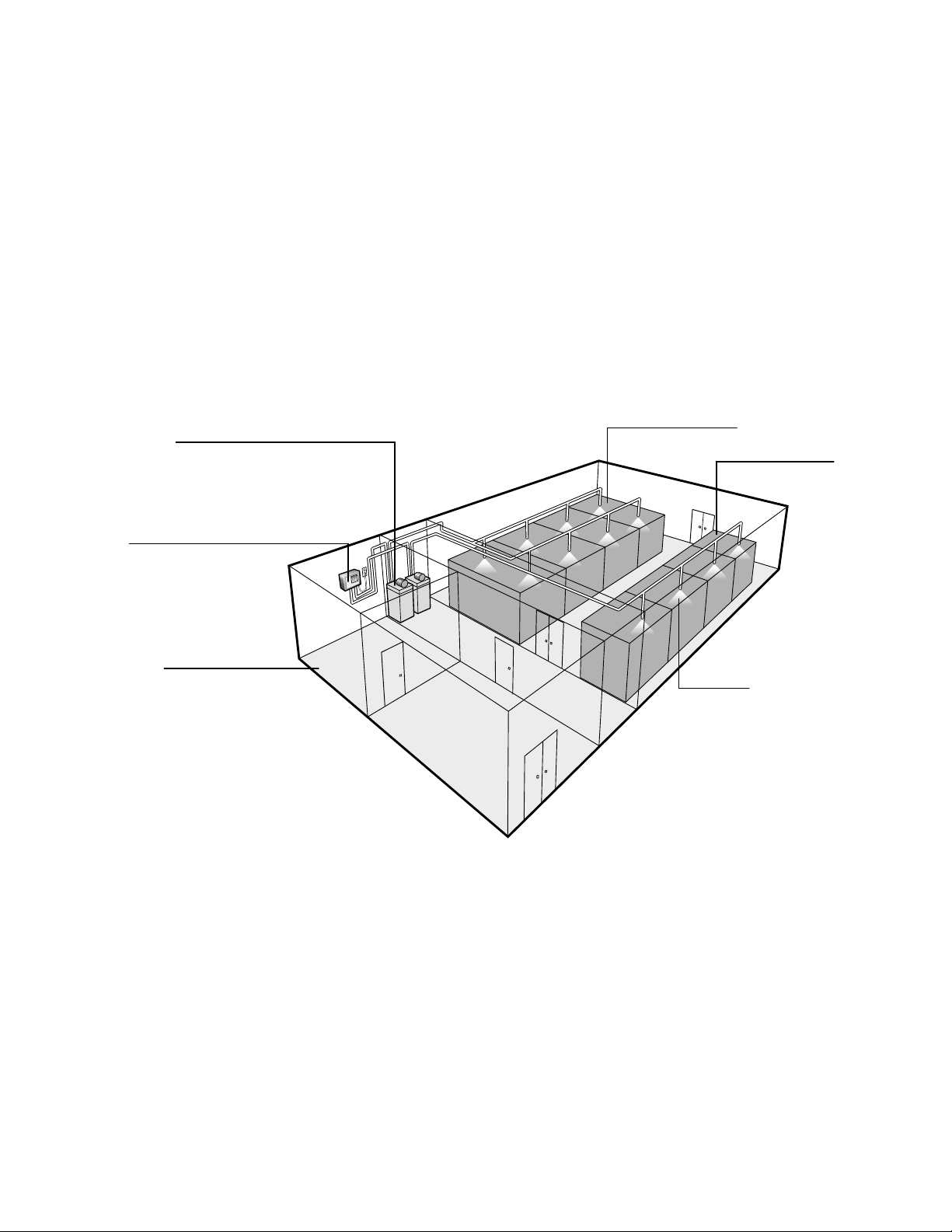

Component Layout............................................................................................................................6

Hatchery Disinfectant System ........................................................................................................6

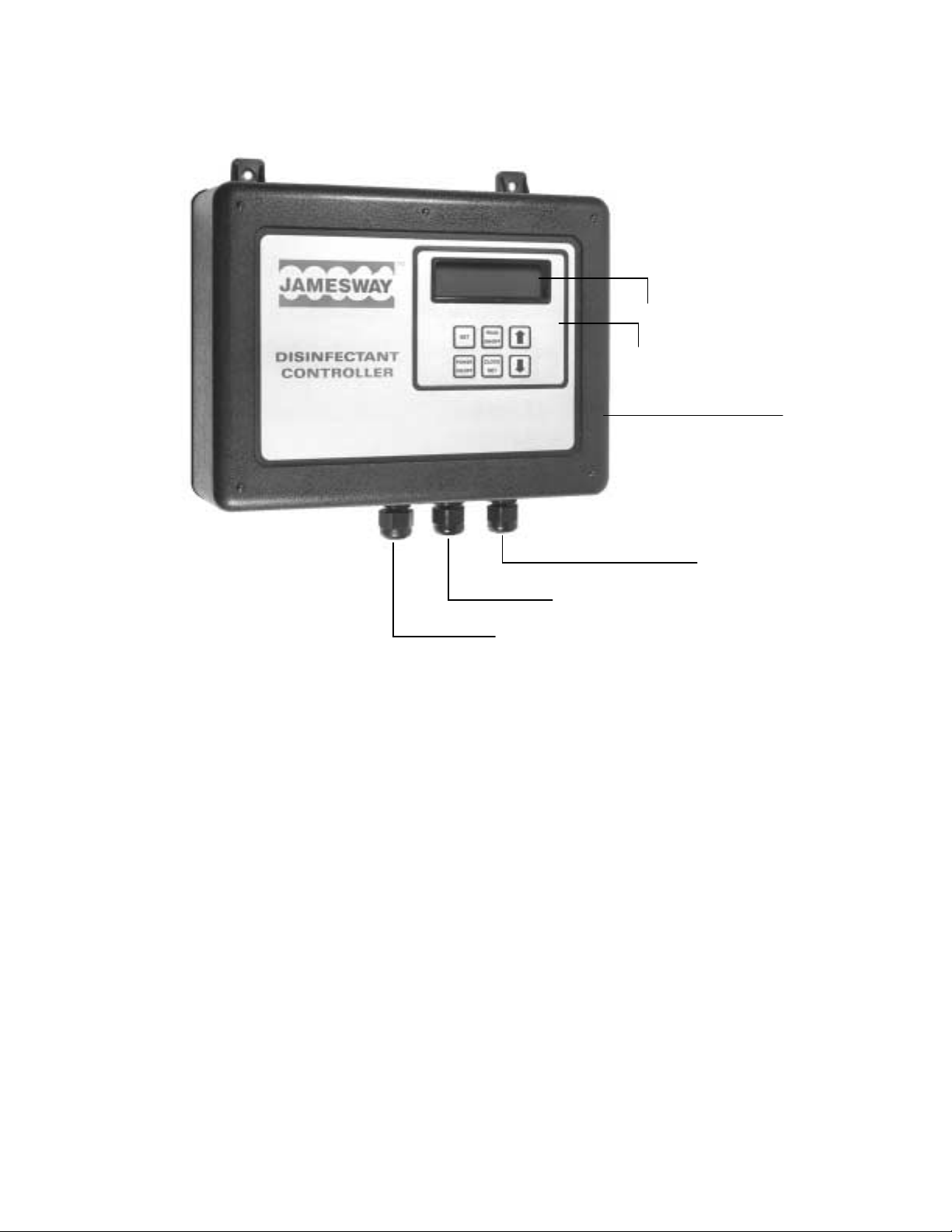

Electronic Controller Features ..........................................................................................................7

Hatchery Sanitation.............................................................................................................................8

General .............................................................................................................................................8

Disinfectants .....................................................................................................................................8

Installation ...........................................................................................................................................9

General .............................................................................................................................................9

Location ..........................................................................................................................................10

Atomizer Units ..............................................................................................................................10

Test Point Locations .....................................................................................................................10

The Electronic Controller and Dilution Tanks................................................................................10

The Voltage Select Switch ..............................................................................................................11

Mounting the Electronic Controller..................................................................................................11

Atomizer Positioning .......................................................................................................................12

Recommendations for Installation ................................................................................................12

Quick Connections .......................................................................................................................12

Installation in Jamesway Incubators and Hatchers.........................................................................13

The Multi-Stage Incubator ............................................................................................................13

The Common Wall Hatcher ..........................................................................................................13

The PX Hatcher............................................................................................................................14

The Single Stage ACI Incubator or Hatcher .................................................................................15

Operation ..........................................................................................................................................16

General ...........................................................................................................................................16

The Electronic Controller ................................................................................................................16

Programming the Electronic Controller...........................................................................................17

Automated Operation ...................................................................................................................17

Programming Functions ...............................................................................................................18

Reviewing the Program ................................................................................................................20

Preventative and Corrective Maintenance ........................................................................................21

General ...........................................................................................................................................21

Filter Inspection and Cleaning ........................................................................................................21

Atomizer (Nozzle) Inspection..........................................................................................................22

Main Feed Line Test........................................................................................................................22

Disinfectant Usage ............................................................................................................................23

General ...........................................................................................................................................23

Properties of Disinfectants..............................................................................................................23

Recommended Spray Intervals ......................................................................................................24

Guidelines.......................................................................................................................................24