MUST READ THIS BEFORE RUNNING

Running a nitro kit is fun and easy, but to make this a safe • Clean oil and dirt from chassis with a degreaser.

and good experience you must observe a few rules. This Precautions

kit is extremely fast, easily over 40MPH, and can seriously • This kit is not a toy. Always run car with a second

injure someone if you are not careful. person as a spotter and pitman.

Where to run car? • Hot Parts - The pipe, manifold, engine and head are very

• Any running area you choose must be dry. Do not run hot and will cause burns.

car near any water or wet dirt.

• Do not run on public streets. It is very easy to have the • Rotating Parts - Keep hands away from the drive train,

car run over or damaged by hitting the curb. wheels, and engine when engine is running.

• Do not operate car in tight confined places. The car is

very fast and will easily hit something. • Radio - Check batteries life before running the car. If

• Do not run near people or animals. radio does not have full control of the car with steering

and/or throttle/brake do not run until corrected. Failure to

• Due noise, you will want to consider the surrounding correct this will result in possible injury and damage to the

area when operating the car. car or property.

• Do not operate the car at night. You will not be able to

drive it without hitting something. • Glow fuel - Do leave the glow fuel unattended with the lid

• Do not operate the car indoors. Engine exhaust is not off. Fuel contains Methanol and Nitro Methane and is

healthy. flammable and poisonous.

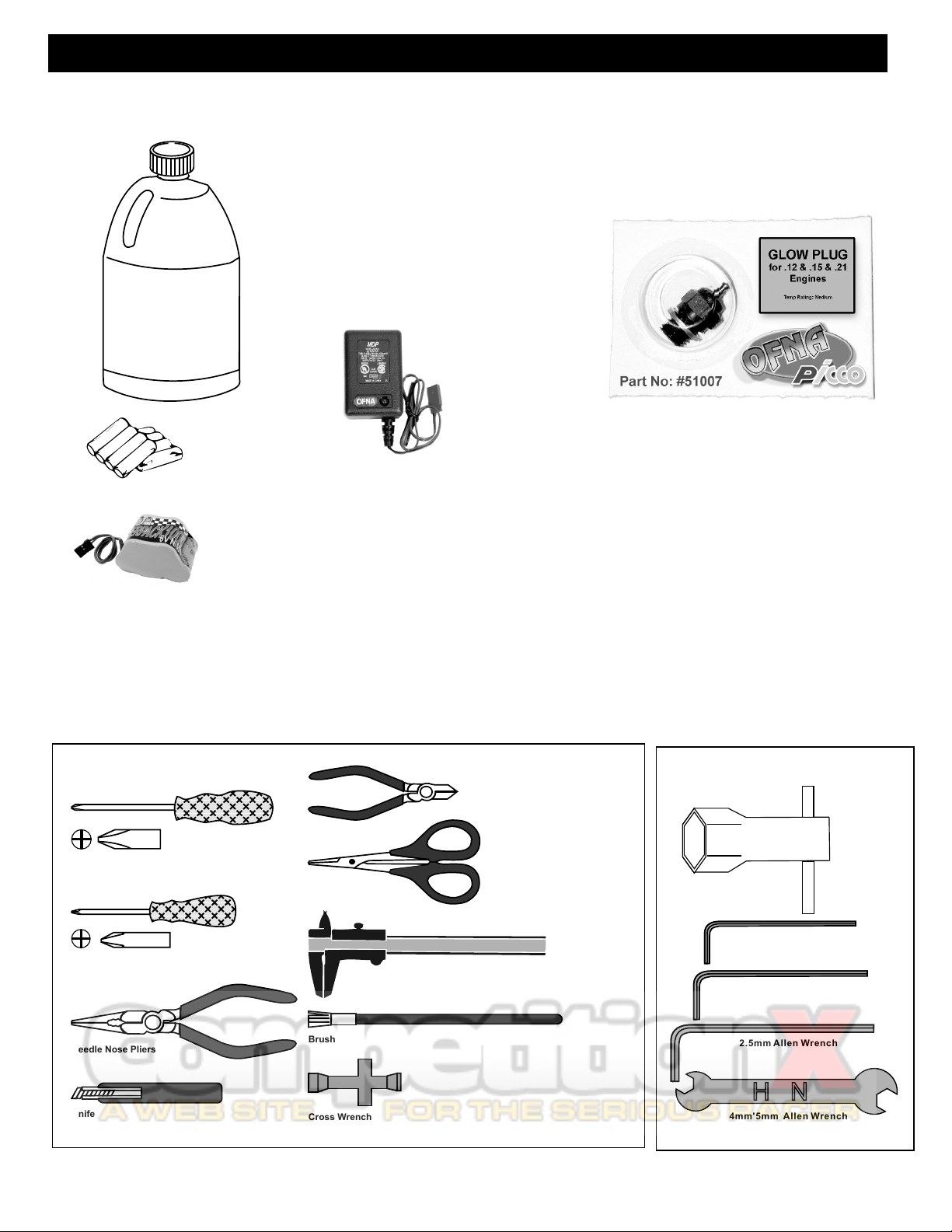

Glow Fuel Store fuel in cool ventilated location. Refer the glow fuel

• Glow fuel is poisonous!

• Glow fuel is flammable! label for additional precautions.

• Do not leave in fuel bottle with lid off at any time.

• Do not use any fuel other than glow fuel in this engine. • Car Fuel tank - Never store fuel in car tank, it will ruin the

engine if left in tank.

First Time Starting the Engine

Caution! When starting engine make sure the following is • Always turn off the car BEFORE turning off radio.

observed.

• Set engine Master needle to 3 turns (rich setting) • DAMAGE DUE CAR RUN AWAY IS NOT A WARRANTY

• Do not do this alone, get an experienced friend to help at ISSUE.

first.

• Fill fuel tank, try not to spill fuel. Do not spill fuel on IF YOU DO NOT BREAK-IN ENGINE

receiver CORRECTLY, MAINLY AT LOW RPM,

• Hold car off the ground, so it will not runaway when first

starts YOU WILL BREAK THE CONNECTING

• Turn on Radio and check the linkage before starting ROD!

engine.

• Turn on car receiver battery switch.

• Always have an air filter on the carburetor to keep dirt FAILURE TO NOT READ AND

out.

FOLLOW BREAK-IN ENGINE

Engine Break-in

• See Engine Page. INSTRUCTIONS WILL VOID

Emergency Stopping Engine When Running

• Remove air filter and cover carb. intake. WARRANTY!

• Squeeze fuel line and hold until engine stops.

• With a rag, cover exhaust outlet.

Storing Car After Running

• Remove fuel from tank and fuel lines

• Turn off radio in car

• Put a few drops of after run in engine to keep it from

rusting.

The car is very fast

and will too easily hit someone.