J&E Hall Fridgewatch 2100 Installation guide

Publication 3-58

Issue 1.1 : 01/08

Installation, Operating and Maintenance Manual

Fridgewatch®2100 Controller Mk4

This publication is applicable to the following J & E Hall

International Compressors and Packages:

HallScrew 2000 Series Compressors: HS 2018 - HS 2024

HallScrew 2100 Series Compressors

HallScrew 3100 and 3200 Series Compressors

HallScrew 4200 Series Compressors

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 2 of 152 Issue 1.1 : 01/08

J & E Hall International©2008

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying, recording or by any information

storage or retrieval system, without permission in writing from the copyright holder.

The copyright in this publication shall be and remain the sole property of J & E Hall International.

®FRIDGEWATCH is a registered trade name of J & E Hall International.

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 3 of 152

Safety

Electrical wiring must be sized and installed to such a standard as to

meet the requirements of the national or local codes pertaining to the

area in which the installation is taking place.

The electrical power used in this equipment is at a voltage high enough to

endanger life. Before undertaking maintenance or repair procedures on

electrical equipment, personnel must isolate equipment from the electrical

supply and test to verify that isolation is complete. Precautions must be

taken to prevent circuits being inadvertently energised, for example,

withdraw the mains fuses, or, if this is not practicable, disconnect the

equipment from the supply before work commences.

If the supply cannot be disconnected or must remain connected to permit

functional testing, fault diagnosis and repair should only be undertaken by

persons who are aware of the hazard and who have taken adequate

precautions to avoid direct contact with dangerous voltages.

If electrical equipment overheats or a fault occurs, it must be

disconnected from the supply and allowed to cool. Overheating may

damage the insulation system, cables, mouldings, gaskets and seals.

The materials used in these components may contain complex organic

compounds which, when degraded by heat or electrical action, produce

chemical compounds in gaseous, liquid or solid forms. Many of these

gaseous and liquid product compounds are highly flammable and toxic.

If it is necessary to extinguish a fire in electrical equipment, follow the

advice given in the Fire Precautions Act 1971, ‘Guide to Fire Precautions

in Existing Places of Work that require a Fire Certificate’ available from

HMSO. Do not approach the equipment until the fire has been

extinguished and the equipment is cool.

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 4 of 152 Issue 1.1 : 01/08

Contents

Safety ........................................................................................................................................... 3

1. About this Publication................................................................................................9

1.1. Safety Warnings and Symbols............................................................................................... 9

1.2. Units of Measurement ............................................................................................................9

1.3. Terminology............................................................................................................................ 9

1.4. Ordering Extra Copies............................................................................................................ 9

2. Care and Protection of Fridgewatch ........................................................................10

2.1. Anti-Static Precautions.........................................................................................................10

2.2. Electrical Interference........................................................................................................... 11

2.3. Prolonged Storage................................................................................................................ 11

3. Personnel Permitted to Install, Commission and Maintain Fridgewatch...................11

4. General Description.................................................................................................12

4.1. Construction.......................................................................................................................... 13

4.2. Technical Data...................................................................................................................... 14

5. Principles of Control.................................................................................................20

5.1. Compressor Capacity Control.............................................................................................. 20

5.1.1. HallScrew 2000 Series Compressors.............................................................................. 20

5.1.2. HallScrew 2100 and 3100 Old Series Compressors....................................................... 20

5.1.3. HallScrew 3100 New Series, 3200 and 4200 Series Compressors ............................... 21

5.2. Proportional, Integral and Derivative (PID) Control ............................................................. 22

5.2.1. Proportional Band............................................................................................................ 22

5.2.2. Integral Action Time......................................................................................................... 24

5.2.3. Derivative Action Time..................................................................................................... 24

5.2.4. PID Control Set-up........................................................................................................... 24

5.3. Basics of Starting and Stopping Compressors.................................................................... 25

5.4. Set Point Deviation............................................................................................................... 25

5.5. Master/Slave Operation........................................................................................................ 26

5.5.1. Starting the Master Compressor...................................................................................... 26

5.5.2. Starting and Stopping the Slave Compressor................................................................. 27

5.5.3. Master/Slave Operation With a Fridgewatch 2100 Controller Controlling

More than One Compressor............................................................................................ 27

5.6. Starting and Stopping the First Compressor........................................................................ 27

5.7. Compressor Running Order................................................................................................. 28

5.8. Capacity Control by Fridgewatch 2100................................................................................ 30

5.8.1. Auto Capacity Control...................................................................................................... 30

5.8.2. Manual Capacity Control ................................................................................................. 30

5.8.3. Remote Capacity Control................................................................................................. 30

5.9. Limiting Inputs ...................................................................................................................... 31

5.9.1. Control Strategy for Limiting Inputs................................................................................. 32

5.9.2. Current Limiting................................................................................................................32

5.10. Limiting on P4 Input.............................................................................................................. 32

6. Installation ...............................................................................................................35

6.1. Analogue Inputs for Sensing Start, Stop and Set Point Values........................................... 35

6.1.1. Using Two Start, Stop and Set Point Values................................................................... 35

6.1.2. Digital Outputs .................................................................................................................36

6.2. Installing Transducers ..........................................................................................................36

6.3. Using Fridgewatch 2100 to Drive Relays............................................................................. 36

6.4. Power Supply Connections (Lower Half of Enclosure)........................................................ 38

6.4.1. Panel Heater....................................................................................................................38

6.5. Wiring Connections to dc Circuits (Upper Half of Enclosure).............................................. 38

6.5.1. Opto-Electronic Liquid Sensor Interface Unit.................................................................. 39

6.5.2. Connections to Economiser Solenoid Valves ................................................................. 39

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 5 of 152

6.5.3. Wiring Connections to Electronic Cards.......................................................................... 39

6.5.4. Jumper Connections on Electronic Cards....................................................................... 39

6.6. Fridgewatch Highway Connections...................................................................................... 41

6.7. Summary of Master/Slave Connections............................................................................... 42

7. Cards and Wiring Connections................................................................................45

7.1. FCPS1 Power Supply Card.................................................................................................. 45

7.2. 3SCOP1 Relay Outputs Card .............................................................................................. 46

8. User Interface..........................................................................................................62

8.1. Home Page........................................................................................................................... 62

8.1.1. Event Codes .................................................................................................................... 62

8.2. Contents ............................................................................................................................... 64

8.3. Measured Points................................................................................................................... 64

8.4. Operator Settings and Configuration Settings ..................................................................... 64

8.5. Mode Selection..................................................................................................................... 64

8.6. Information............................................................................................................................ 64

8.7. Status Indicators................................................................................................................... 65

8.7.1. Micro Ok........................................................................................................................... 65

8.7.2. Trip................................................................................................................................... 65

8.8. Operator Input Buttons......................................................................................................... 65

8.8.1. Acknowledge.................................................................................................................... 65

8.8.2. Configuration Settings ..................................................................................................... 66

8.8.3. Home Page...................................................................................................................... 66

8.8.4. Previous Menu................................................................................................................. 66

8.8.5. Stop Compressor(s) (All Modes)..................................................................................... 66

8.8.6. Enter................................................................................................................................. 66

8.8.7. Scroll Up - Raise Setting - Start/Load Compressor (Manual Control Only).................... 67

8.8.8. Lower Setting – Unload Compressor (Manual Control Only).......................................... 68

8.9. Supervisor Keyswitch........................................................................................................... 68

9. Commissioning........................................................................................................70

9.1. Authority to Use the Supervisor Key.................................................................................... 70

9.2. Checks to be Made Prior to Supplying Power to Fridgewatch 2000................................... 70

9.3. Transducer Calibration and Potentiometer Adjustment....................................................... 71

9.4. Inputting Configuration and Operator Settings During Commissioning,

Operating Mode for the First Start........................................................................................ 71

9.4.1. Inputting Configuration Settings During Commissioning................................................. 71

9.4.2. Inputting Operator Settings During Commissioning........................................................ 74

9.4.3. Operating Mode for the First Start................................................................................... 74

9.5. Changing Operator Settings after Commissioning .............................................................. 74

9.6. Changing Configuration Settings after Commissioning....................................................... 74

9.7. Changing the Operating Mode............................................................................................. 76

9.8. Checking the Software Version Number.............................................................................. 76

9.9. Printing or Downloading the Settings List............................................................................ 77

10. Event Codes............................................................................................................78

10.1. Information Only Events....................................................................................................... 78

10.2. Trip Events............................................................................................................................ 78

10.2.1. Compressor Healthy ‘Off’................................................................................................. 78

10.3. Event Codes Description...................................................................................................... 80

11. Settings ...................................................................................................................87

11.1. Operator Settings S1/S39 .................................................................................................... 87

11.2. Configuration Settings S41/109 ........................................................................................... 98

12. Maintenance..........................................................................................................122

12.1. Calibration of Pressure Transducers.................................................................................. 122

12.2. Calibration of Temperature Transducers........................................................................... 123

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 6 of 152 Issue 1.1 : 01/08

12.3. Calibration of Motor Current............................................................................................... 124

12.4. Calibration of LVDT 4 to 20 mA Signal - HS 2000 Series Compressors........................... 125

12.5. Calibration of LVDT 4 to 20 mA Signal – HS 3100 New Series, HS 3200 and

HS 4200 Series Compressors............................................................................................ 125

12.6. Fitting a New RAMP4 Processor Card............................................................................... 125

12.7. Checking and Replacement of Lithium Back-up Battery................................................... 128

12.8. Maintenance Check List..................................................................................................... 128

13. Spares...................................................................................................................129

13.1. Fuses for Mains Input......................................................................................................... 129

13.2. Fuse for Panel Anti-condensation Heater (if fitted)................Error! Bookmark not defined.

13.3. Fuses for Power Supply Card FCPS .....................................Error! Bookmark not defined.

13.4. Electronic Cards.....................................................................Error! Bookmark not defined.

13.4.1. Electronic Card Compatibility ........................................................................................ 129

14. Appendix 1 - Measured Points Reference .............................................................130

15. Appendix 2 - Event Codes E1/E47 Quick-Reference.............................................131

16. Appendix 3 - Settings Record................................................................................133

16.1. Compressor Number/Compressor Serial Number Record................................................ 133

17. Appendix 4 - Start-up Timing Diagram...................................................................148

18. Index......................................................................................................................150

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 7 of 152

List of Figures

Fig 1 Multiple Compressors With Common or Individual Oil Separator/Reservoirs.............................. 13

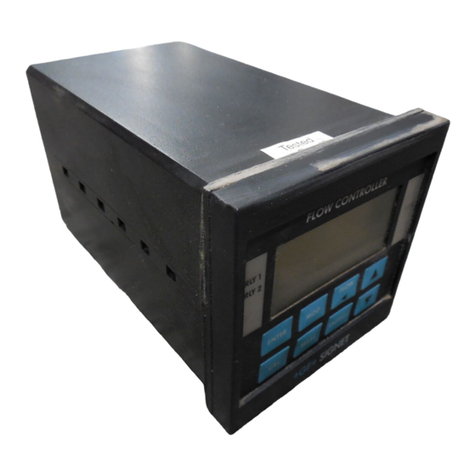

Fig 2 Fridgewatch 2100 Mk4 Controller ................................................................................................. 15

Fig 3 Display Details............................................................................................................................... 16

Fig 4 Internal Layout of Fridgewatch 2100 Panel................................................................................... 17

Fig 5 Enclosure Dimensions and Details of Cable Entries..................................................................... 19

Fig 6 Slide Valve Position Switch Approximation of LVDT 4 to 20 mA Signal ...................................... 21

Fig 7 Proportional, Integral and Derivative (PID) Control.......................................................................23

Fig 8 Possible Compressor Start/Stop and Capacity Control Modes.................................................... 29

Fig 9 Limiting Inputs - Examples ............................................................................................................ 34

Fig 10 Transducer Installation ................................................................................................................ 37

Fig 11 Connecting Diodes ...................................................................................................................... 38

Fig 12 Economiser Arrangements: Wiring to Liquid Line Solenoid Valves............................................ 40

Fig 13 Typical Fridgewatch Highway Connections ................................................................................ 41

Fig 14 Wiring Connections for Master/Slave Without External Run Request or Run Enable Signal.... 43

Fig 15 Wiring Connections for Master/Slave With External Run Request or Run Enable Signal......... 44

Fig 16 FCPS1 Power Supply Card and Wiring Connections................................................................. 45

Fig 17 3SCOP1 Relay Outputs Card...................................................................................................... 46

Fig 18 Wiring Connections to 3SCOP1 Relay Outputs Card for Compressor 1.................................... 47

Fig 19 Wiring Connections to 3SCOP1 Relay Outputs Card for Compressors 2 and 3........................ 48

Fig 20 RAMP4 Processor Card .............................................................................................................. 49

Fig 21 ANP8 Display Card + Display...................................................................................................... 50

Fig 22 Wiring Connections to RAMP4 Processor Card ......................................................................... 51

Fig 23 3MIO1 Input/Output Card for Compressor 1............................................................................... 52

Fig 24 Wiring Connections to 3MIO1 Input/Output Card for Compressor 1.......................................... 53

Fig 25 3MIO2 Input/Output Card for Compressors 2 and 3................................................................... 57

Fig 26 Wiring Connections to 3MIO2 Input/Output Card for Compressors 2 and 3.............................. 58

Fig 27 Menu Structure ............................................................................................................................ 63

Fig 28 Looking at or Changing Configuration Settings .......................................................................... 72

Fig 29 Looking at or Changing Operator Settings.................................................................................. 75

Fig 30 Changing the Operating Mode .................................................................................................... 77

Fig 31 Identifying and Clearing Trip Events, Reasons for Normal Stop and Reason for Trip............... 79

Fig 32 Flowchart to Assist in Adjusting Start Value/Set Point/Stop Value Times.................................. 94

Fig 33 Calibration of LVDT 4 to 20 mA Signal – HS 3100 New Series, HS 3200 and HS 4200 Series

Compressors........................................................................................................................... 126

Fig 34 Compressor Start-up Timing Diagram ...................................................................................... 148

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 8 of 152 Issue 1.1 : 01/08

List of Tables

Table 1 Technical Data........................................................................................................................... 14

Table 2 Transducer Inputs...................................................................................................................... 35

Table 3 Rule for Selecting Controlling Parameters for Two Start Value/Set Point/Stop Value Sets .... 36

Table 4 Wiring Connections to Electronic Cards.................................................................................... 39

Table 5 E14 High or Low P6 (Pressure or Temperature) ...................................................................... 83

Table 6 Determining Compressor Running Order Priority..................................................................... 88

Table 7 Run Enable Required in Different Operating Modes - Values for S14..................................... 91

Table 8 Operating Mode Indication Using Setting S19.......................................................................... 92

Table 9 Initial Load Values on Starting................................................................................................... 96

Table 10 Transducer/Transmitter Types and Ranges ........................................................................... 99

Table 11 Swept Volumes of HallScrew Compressors ......................................................................... 101

Table 12 Capacity Control Valve Application and Operation............................................................... 104

Table 13 Slide Valve Position Indication for HallScrew Compressors................................................. 105

Table 14 Slide Valve Position Options - Values For S63..................................................................... 106

Table 15 Values for S75 to S80 Current Date and Time ..................................................................... 109

Table 16 Maintenance Check List........................................................................................................ 128

Table 17 Fuses ..................................................................................................................................... 129

Table 18 Electronic Cards .................................................................................................................... 129

Table 19 Measured Points Quick-Reference ....................................................................................... 130

Table 20 Measured Points Function and Settings Cross-Reference................................................... 130

Table 21 Compressor Number/Compressor Serial Number Record................................................... 133

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 9 of 152

1. About this Publication

These instructions have been prepared according to the following

standards:

BS 4884 : Technical Manuals:

Part 1 : 1992 Specification for Presentation of Essential

Information.

Part 2 : 1993 Guide to Content.

Part 3 : 1993 Guide to Presentation.

BS 4899 : User’s Requirements for Technical Manuals:

Part 1 : 1991 Content.

Part 2 : 1992 Presentation.

BS 4899 is based on the principles of BS 4884.

BS 5378 : Part 2 : 1982 Safety Signs.

1.1. Safety Warnings and Symbols

The system of safety warnings and symbols is based on BS 5378 :

Part 2 : 1982 Safety Signs and BS 4884 : Technical Manuals : Part 1 :

1992 Specification for Presentation of Essential Information.

WARNING

This denotes an immediate hazard with a high likelihood

of personal injury or death if instructions, including

recommended precautions, are not followed. There is

also a potential risk of damage to the product, process

or its surroundings.

CAUTION

This draws attention to instructions which must be

complied with to avoid damage to the product, process

or its surroundings.

NOTE: draws attention to important additional

information.

1.2. Units of Measurement

Quantities are expressed in SI units or SI derived units.

1.3. Terminology

Terminology, abbreviations and acronyms are those currently in use

throughout the refrigeration and air conditioning industry.

1.4. Ordering Extra Copies

Obtain extra copies of these instructions from the address below:

J & E Hall International Telephone: +44 (0) 1634-731-400

Engineering & Projects, Fax: +44 (0) 1634-731-401

Sir Thomas Longley Road, Website: www.jehall.co.uk

Medway City Estate,

Rochester,

Kent ME2 4DP

England

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 10 of 152 Issue 1.1 : 01/08

2. Care and Protection of Fridgewatch

CAUTION

If welding is to be carried out in the vicinity of the

Fridgewatch Controller or any other items of plant

containing semi-conductor devices, for example,

transistors and microprocessors, the welding

equipment must be adequately earthed adjacent to the

point of weld. The Fridgewatch Controller or other

electronic devices must not be positioned between the

site where the welding is taking place and the point of

earth, or irrevocable damage may be caused to the

electronics, with possible consequential damage to the

plant.

2.1. Anti-Static Precautions

The electronic cards fitted to Fridgewatch are electrostatic sensitive.

That is to say, damage to the card or its components can occur as the

result of electrostatic discharge from or through personnel. To protect

electronic cards and components, precautions against electrostatic

hazards must be taken according to BS EN 100015: Part 1: 1991. Note

the following:

•Persons handling electronic cards must be earthed, in

accordance with BS EN 100015: Part 1: 1991, to the earth

terminal on the Fridgewatch Controller or other suitable

earthing point.

WARNING

The earth bonding device, for example, wrist strap and

its application, must conform to BS EN 100015: Part 1:

1991. Failure to use the correct earth bonding device in

the correct manner can result in death or serious injury

if there is accidental contact with hazardous voltages.

•Immediately after removing a card from the Fridgewatch

Controller, place the card in an electrostatic conductive or

dissipative envelope. The card should remain in its envelope

other than when the card is installed or being worked on.

•When working on a card, for example, when replacing the

lithium battery on the RAMP Processor Card, the card must

be placed on an earth bonded electrostatic conductive or

dissipative mat and the person carrying out the work must

bonded to earth as described above.

•Spare cards must be kept in an electrostatic conductive or

dissipative envelope, one card per envelope. Each envelope

should be sealed and stored in a cool, dry place well away

from strong magnetic sources.

•Never remove or replace an electronic card with the

Fridgewatch Controller power supply turned on.

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 11 of 152

2.2. Electrical Interference

To avoid problems of electrical interference, all low voltage wiring

(transducers, data communications and 24 V dc) must be adequately

separated from higher voltage ac wiring (110 V, 240 V, 415 V or higher).

A separation of 150 mm is desirable but not always achievable within

control panels. Low voltage and higher voltage cables should cross at

right-angles.

2.3. Prolonged Storage

If the Fridgewatch Controller, or the plant of which it forms a part, is not to

be installed immediately but held in store, observe the following points:

•The Fridgewatch Controller should preferably be stored

indoors, in a well ventilated, clean, warm and dry

environment. If the equipment is stored outside, protection

from the elements must be provided; coverings should be

selected and arranged to reduce the risk of condensation.

•Fridgewatch contains programmed integrated circuits

(memory chips) which are sensitive to low temperatures.

The controller should not be exposed to ambient

temperatures below -10 °C.

3. Personnel Permitted to Install, Commission and Maintain Fridgewatch

It is essential that only authorised and competent personnel are allowed

to install, commission and maintain the Fridgewatch Controller. A permit

to work system should be introduced before commissioning begins, and

should be rigorously enforced thereafter.

Any person rendering assistance or under training must be supervised by

the authorised competent person who has responsibility for safety.

Personnel must be familiar with the plant’s construction, operation and

the hazards involved. All personnel should make a thorough study of

these instructions before undertaking installation, commissioning,

maintenance or repair procedures.

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 12 of 152 Issue 1.1 : 01/08

4. General Description

The Fridgewatch 2100 Mk4 Controller is a compact integrated solution for

the control and management of refrigeration systems based on the J & E

Hall International HallScrew compressor. Fridgewatch replaces the

collection of pressure, temperature and motor current controllers, timers,

relays and programmable logic controllers (PLCs) that might otherwise be

used. To the basic functions: compressor starting and stopping, running

order priority (lead/lag), safety monitoring and capacity control,

Fridgewatch 2100 adds a number of enhancements which permit

compressor operation to be optimised to suit the running conditions.

Other facilities include the ability to communicate with another

Fridgewatch Controller and/or Compressor Management System.

Remote display and permanent logging facilities can be provided by

connecting a VDU and a printer.

1, 2 or 3 compressor versions of the Fridgewatch 2100 Controller are

available, the physical differences being confined to the number of

input/output cards fitted (1 for each compressor). This feature provides

for simple upgrading in the field should additional compressors be added

later and also means that display and operator inputs are common to all

versions for ease of operator familiarisation and use.

Linked to another Fridgewatch 2100 or a Fridgewatch 2000 Controller,

the Fridgewatch 2100 Controller can be run in a master/slave

configuration.

Fridgewatch 2100 monitors the safe operation of the plant and, in the

event of a fault condition, displays where the fault lies. However, fault

detection does not rely on the program running in the microprocessor. In

common with conventional relay based control panels, the signal to stop

the compressor is derived from the electrical contacts of mechanical

pressure and temperature safety devices. Primary pressure and

temperature safety inputs are linked in series so that a fault condition will

automatically remove the run signal to the compressor motor, quite

independent from the microprocessor. Safety inputs and all other digital

inputs are read into Fridgewatch 2100 in the form of 24 V dc signals.

Either cooled medium temperature or suction pressure can be used as

the controlling parameters. Compressor start and stop temperature or

pressure variables, and the set point value for capacity control, are

sensed by transducers from the same point on the plant or from two

different points. These transducers are connected to analogue inputs 1

and 2 mounted on the compressor 1 3MIO1 input/output card.

Compressor motor current, read from a current transformer, can be used

by Fridgewatch 2100 to inhibit compressor loading if current consumption

reaches a predetermined threshold, or to unload if consumption

continues to rise. Similar limiting functions are also available from other

analogue inputs, for example, suction pressure. Limiting is also available

via digital inputs for system specific limiting requirements.

Compressor slide valve position can be read and displayed from the

4 to 20 mA signal from the Linear Variable Displacement Transducer

(LVDT) fitted to HallScrew 2000 series compressors. The minimum,

intermediate and maximum slide valve position switches, part of the

LVDT, and the three reed switches fitted to HallScrew 2100 series

compressors, can be used to initiate an event.

Fridgewatch 2100 can display key system temperatures, pressures and

compressor hours run.

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 13 of 152

Fridgewatch 2100

Controller

Fridgewatch 2100 can

control a single

package unit fitted

with one, two or three

HallScrew

compressors using a

common oil separator

or

Fridgewatch 2100 can

control one, two or

three package units

each comprising a

HallScrew compressor

and oil separator

Fridgewatch 2100

Controller

Oil Separator/Reservoir

Oil Separator/Reservoir

Oil Separator/Reservoir

Oil Separator/Reservoir

Fig 1 Multiple Compressors With Common or Individual Oil Separator/Reservoirs

4.1. Construction

The Fridgewatch 2100 Controller enclosure, to IP43 (IP55 available as an

option), is divided into two completely separate sections as illustrated in

Fig 2, Fig 3 and Fig 4. The relay outputs (240 V ac or 110 V ac) required

to drive the various solenoid valves, along with the oil separator/reservoir

heater outputs and power supply connections, are located in the lower

half of the enclosure, completely isolated from the 24 V dc electronics in

the upper half. A door interlocked mains isolator prevents access to the

lower section unless the isolator has been turned to the ‘off’ position.

Common

Discharge

Line

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 14 of 152 Issue 1.1 : 01/08

The display indicators, operator input buttons, Supervisor Keyswitch and

audible alarm are mounted on the door to the upper half of the enclosure.

The main microprocessor logic card, mounted on the back of the door,

contains the program held in flash erasable programmable read-only

memory (FLASH EPROM) for security; data on FLASH EPROM is

impervious to power supply fluctuations or even complete loss of power

for an indefinite period of time. All control settings and stored variables

are held in random access memory (RAM), backed up by a lithium

battery with an expected life of 8 years.

To guard against non-specific microprocessor malfunctions, perhaps as a

result of exceptional power supply fluctuations, the Fridgewatch 2100

Controller incorporates a Watchdog device which continuously monitors

the microprocessor all the time it is running. If the Watchdog detects a

potential fault condition, it automatically resets the microprocessor. After

restarting, Fridgewatch returns to the previous mode of control. If this

was an auto start/stop mode and there is a demand for duty, Fridgewatch

restarts the compressor (subject to normal starting/running parameters).

4.2. Technical Data

Enclosure To IP43 (IP55 available as an option)

Overall dimensions 670 mm high x 360 mm wide x 150 mm deep; refer to Fig 5.

Weight 19 kg

Compressor and

auxiliaries run signals 40 mA maximum at 24 V dc

Back-up battery Style: disc. Nominal volts 3.0 V measured between the

RAMP4 card 0 V tab and the battery face.

Estimated life 8 years. Recommended replacement time

every 5 years or when the voltage drops to 2.7 V.

Relay ouputs 240 V ac or 110 V ac

Relay contact rating 8 A continuous at 250 V ac, 3 A inductive at 250 V ac

Wiring inside panel Use 0.5 mm2cable

1Power supply 110/240 V ac, 50 Hz to 60 Hz. Check the position of the

jumper on the FCPS1 power supply card; refer to Fig 16.

1Power may be taken from a line and neutral supply. If power is derived from a

transformer, the common side of the secondary winding must be earthed. Centre

tapped earthed type transformers MUST NOT be used with the standard Fridgewatch

2100 panel; contact J & E Hall International.

Table 1 Technical Data

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 15 of 152

Fig 2 Fridgewatch 2100 Mk4 Controller

Mains

Isolator

1

S

0

Supervisor

Keyswitch

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 16 of 152 Issue 1.1 : 01/08

Enlargement of Fridgewatch 2100 Display

Button Legend Function Ref For Description

☺MICRO OK Extinguishes to indicate a microprocessor fault

TRIP ‘Flashes’ to indicate a trip event.

ACKNOWLEDGE Press to acknowledge trip event.

CONFIGURATION

SETTINGS

Input/change Configuration settings.

HOME PAGE Return to Home page from any menu page.

PREVIOUS MENU Return to previous menu level.

STOP

COMPRESSORS (ALL

MODES)

Stop compressor.

ENTER Select the active menu item.

NAVIGATION

BUTTONS

In manual control mode, start and load/unload the

compressor. Scroll through points and settings lists.

Change Operator and Configuration setting values using

the Supervisor Key.

SUPERVISOR KEY

Key operated switch permits modification of Operator and

Configuration setting values, change operating mode,

accept/enter selections and with ‘manual’ start/stop –

‘manual’ capacity control mode selected, allows the

compressor to be loaded and unloaded manually by the

operator.

Fig 3 Display Details

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 17 of 152

Fig 4 Internal Layout of Fridgewatch 2100 Panel

3SCOP1 Cards;

refer to Fig 17

Earth Connecting Block

FCPS1 Card;

refer to Fig 16

MCB

Mains

Isolator

Thermistor/Optor Sensor

Conditioning Unit(s)

Mounting

Board

3MIO1 Card for

Comp 1: refer

to Fig 23 3MIO2 Card for Comp 2: refer to Fig 25

Comp 1 Comp 2

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 18 of 152 Issue 1.1 : 01/08

Fig 4 (continued) Internal Layout of Fridgewatch 2100 Panel - Door Mounted Items

Door to Lower Half of Enclosure

Door to Upper Half of Enclosure

RAMP4 Processor Card; refer to Fig 20

ANP8 Display Card; refer to Fig 21

Cover,

mounted on

stand-offs,

removed to

show ANP8

and RAMP4

cards.

Fridgewatch 2100 Controller Mk4

Section 3 Publication 3-58

Issue 1.1 : 01/08 Page 19 of 152

Fig 5 Enclosure Dimensions and Details of Cable Entries

360 mm

390 mm

420 mm

Gland Plate

(335 mm x 110 mm)

40 mm

Gland Plate

(230 mm x 110 mm)

Mounting Hole

8 mm Diameter

5 mm

150 mm

187 mm

35

mm

1 Hole 20 mm Diameter

(Incoming 240 V/110 V ac Supply) Third Angle Projection

Not to Scale

Dimensions in mm

600 mm 670 mm

65 mm

35 mm

Fridgewatch 2100 Controller Mk4

Publication 3-58 Section 3

Page 20 of 152 Issue 1.1 : 01/08

5. Principles of Control

The primary requirement of any refrigeration control system is to match

the measured variable (temperature or pressure) as closely as possible

to the desired control value (set point), while at the same time optimising

the use of available compressor capacity.

In this part of the manual we will look first at the basic capacity control

system fitted to HallScrew compressors, then examine the fundamentals

of proportional, integral and derivative control before going on to describe

how Fridgewatch 2100 starts and stops the compressor in single

compressor and master/slave applications. Having grasped the

underlying principles, it is possible to make a reappraisal of the control

system as a whole, and more readily understand the enhancements

possible to the basic control elements by using Fridgewatch 2100.

5.1. Compressor Capacity Control

The capacity control system, common to all HallScrew compressors,

permits compressor capacity to be altered to match loading conditions as

closely as possible.

5.1.1. HallScrew 2000 Series Compressors

The compressor capacity control slide valves modulate capacity between

minimum and maximum (10 % and 100 % of full load). Oil pressure,

generated by the system suction/discharge pressure differential, moves

the capacity control piston attached to one end of the slide valves to load

or unload the compressor. Solenoid valves in the pipe lines supplying

and venting oil to either side of the capacity control piston are energised

(opened) or de-energised (closed) by Fridgewatch 2100 for a timed

period.

Three different methods of slide valve position indication have been fitted

to HallScrew HS 18 to HS 235 and 2000 series compressors; refer to

Table 13 and the descriptions in the HallScrew 2000 compressor

instruction manual, publication 2-49.

The LVDT and NLVDT is provided with three slide valve position

switches: minimum load (10 %), intermediate load (user defined) and

maximum load (100 %). The compressor loading range is divided into

four discrete bands as illustrated in Fig 6.

5.1.2. HallScrew 2100 and 3100 Old Series Compressors

The compressor capacity control slide valve modulates capacity between

minimum and maximum (25 % and 100 % of full load). Oil pressure,

generated by the system suction/discharge pressure differential, moves

the capacity control piston attached to one end of the slide valve in the

load direction, while a compressed spring on the unload side of the piston

moves the piston in the unload direction when the oil pressure is

released. Solenoid valves in the pipe lines supplying and venting oil to

either side of the capacity slide valve piston are energised or de-

energised (opened or closed) by Fridgewatch 2100 for a timed period.

HallScrew 2100 and 3100 old series compressors are not fitted with an

LVDT to supply a 4 to 20 mA signal; three slide valve position reed

switches are provided, one for minimum load (25 %), one for intermediate

load (50 %) and one for maximum (100 %) load. The loading bands are

illustrated in Fig 6.

Table of contents

Other J&E Hall Controllers manuals