J&E Hall Fridgewatch 4000 Installation guide

Publication 3-71

Issue 3.3 : 01/23

Installation, Operating and Maintenance Manual

Fridgewatch®4000 Controller Mk2

Software Version FW40Mk2P3.105 Onwards

This publication is applicable to the following

J & E Hall International Compressors:

HallScrew HSO 2000, HS 3100, HS 3200,

HS 4200, HS 5200 and HS 6200

Series Compressors

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 2 of 270 Issue 3.3 : 01/23

J & E Hall International©2023

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying, recording or by any information

storage or retrieval system, without permission in writing from the copyright holder.

The copyright in this publication shall be and remain the sole property of J & E Hall International.

FRIDGEWATCHis a registered trade name of J & E Hall International.

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 3 of 270

Safety

In common with most other forms of mechanical and electrical

equipment, there are a number of potential hazards associated with

operating and servicing refrigeration plant.

In writing this instruction manual, every emphasis has been given to safe

methods of working. These safety instructions are intended to draw

attention to the potential hazards that could be encountered during

installing, operating and maintaining the plant.

At the same time, it should be emphasised that these notes are not

exhaustive, and are principally intended to draw attention to the most

important points; where necessary, reference is made to other parts of

the manual.

NOTE: The installer is responsible for the correct

installation of equipment, and on completion, the owner

and/or user are responsible for safe operation and

maintenance.

Personnel Permitted to Install, Commission and Maintain the Plant

It is essential that only authorised and competent personnel are allowed

to install, commission and maintain the Fridgewatch Controller. A permit

to work system should be introduced before commissioning begins, and

should be rigorously enforced thereafter.

Any person rendering assistance or under training must be supervised by

the authorised competent person who has responsibility for safety.

Personnel must be familiar with the plant’s

construction, operation and the hazards involved. All

personnel should make a thorough study of these

instructions before undertaking installation,

commissioning, maintenance or repair procedures.

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 4 of 270 Issue 3.3 : 01/23

Electrical

Electrical wiring must be sized and installed to such a standard as to

meet the requirements of the national or local codes pertaining to the

area in which the installation is taking place.

Electrical Isolation

The electrical power used in this equipment is at a voltage high enough to

endanger life.

WARNING

Disconnect the power source before servicing or

repairing electrical equipment.

The only way to be sure

Where there is no local means of isolation or where there is a risk of

reinstatement of the supply, the circuit or equipment to be worked on

must be securely isolated by one of the following methods:

•Isolation using a main switch;

•Distribution board switch (MCB);

•Removal of Cartridge fuses.

Isolation of equipment or circuits using the main switch or distribution

board switch is the preferred method. The point of isolation must be

locked off using a unique key or combination retained by the person

carrying out the work or the appointed person, and a caution notice

attached to the point of isolation.

Where more than one operative is working on circuits supplied from an

isolated distribution board, a multi-lock hasp can be used to prevent

operation of the main isolator until such time that all persons working on

the installation have completed their work and removed their padlocks

from the hasp. If locking-off facilities are not provided on the relevant

switch, then a locked distribution board, which prevents access to the

switch is acceptable provided the key or combination is unique and is

retained by the person doing the work or the appointed person

inadvertent reinstatement of the supply.

Functional Testing

If the supply must remain connected to permit functional testing, fault

diagnosis and repair must only be undertaken by persons who are aware

of the hazard and who have taken adequate precautions to avoid direct

contact with dangerous voltages.

Electrical Hazard in the Event of Fire

If electrical equipment overheats or a fault occurs, it must be

disconnected from the supply and allowed to cool. Overheating may

damage the insulation system, cables, mouldings, gaskets and seals.

The materials used in these components may contain complex organic

compounds, which, when degraded by heat or electrical action, produce

chemical compounds in gaseous, liquid or solid forms. Many of these

gaseous and liquid product compounds are highly flammable and toxic.

If it is necessary to extinguish a fire in electrical equipment, follow the

advice given in the Fire Precautions Act 1971, ‘Guide to Fire Precautions

in Existing Places of Work that require a Fire Certificate’ available from

HMSO. Do not approach the equipment until the fire has been

extinguished and the equipment is cool.

Safe Disposal, End-of-life (EOL)

The controller contains electrical components.At the end of the

controller’s working life, it should not be classed as domestic waste but

be disposed of separately by a registered electrical/electronic waste

recycling company according to local and currently valid legislation.

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 5 of 270

Contents

1. About this Publication ................................................................................................. 14

1.1. Safety Warnings and Symbols ...............................................................................................14

1.2. Units of Measurement............................................................................................................14

1.3. Terminology ...........................................................................................................................14

1.4. Additional Copies ...................................................................................................................14

2. Care and Protection of Fridgewatch ........................................................................... 15

2.1. Anti-Static Precautions...........................................................................................................15

2.2. Electrical Interference ............................................................................................................15

2.3. Prolonged Storage .................................................................................................................15

3. Abbreviations .............................................................................................................. 16

4. General Description .................................................................................................... 17

4.1. Standalone Versions..............................................................................................................17

4.1.1. Human-machine Interfaces (HMI) Displays.....................................................................18

4.1.2. Fridgewatch 4000 Controller (Standalone Arrangement) - Mounting ..............................22

4.1.3. Fridgewatch 4000 Controller (Standalone Arrangement) - HMI Interface .......................23

4.2. Integrated Version..................................................................................................................23

5. Application................................................................................................................... 23

5.1. Plant Control and Monitoring .................................................................................................23

5.1.1. Safety Monitoring ............................................................................................................24

5.1.2. Options For Set Point Control .........................................................................................24

5.1.3. Set Point, Start and Stop Values, Second Set Point and Set Point Override ..................24

5.1.4. Operating Modes.............................................................................................................24

5.1.5. Limiting............................................................................................................................25

5.1.6. Oil Management Systems ...............................................................................................25

5.1.7. Auxiliary Control ..............................................................................................................25

6. Principles of Control.................................................................................................... 26

6.1. Compressor Capacity Control ................................................................................................26

6.1.1. HallScrew HSO 2000 Series Capacity Modulation by Slide Valves ................................26

6.1.2. HallScrew HS 3100 to HSO 6200 Series Capacity Modulation by Slide Valves..............26

6.1.3. Slide Valve Position Signal .............................................................................................27

6.2. Intermediate Load Outputs ....................................................................................................27

6.3. Proportional and Integral (P + I) Control ................................................................................29

6.3.1. Proportional Band ...........................................................................................................29

6.3.2. Integral Action Time ........................................................................................................30

6.3.3. Set Point Temperature/Pressure.....................................................................................31

6.3.4. Evaporator Superheat Set Point/Liquid Level Set Point Value ........................................31

6.3.5. Economiser Superheat Set Point ....................................................................................32

6.4. Starting and Stopping the Compressor ..................................................................................32

6.5. Control Philosophy for Compressor Operation After a Transmitter Failure ............................34

6.6. Capacity Control by Fridgewatch 4000 ..................................................................................34

6.6.1. Auto Capacity Control .....................................................................................................34

6.6.2. Remote Capacity Control ................................................................................................34

6.6.3. Manual Capacity Control.................................................................................................35

6.7. Limiting Inputs........................................................................................................................35

6.7.1. Current Limiting...............................................................................................................35

6.7.2. Suction Pressure Limiting ...............................................................................................35

6.7.3. Discharge Pressure Limiting ...........................................................................................35

6.7.4. Evaporator Cooled Medium Outlet Temperature Limiting ...............................................35

6.7.5. Other Limiting Conditions ................................................................................................36

6.7.6. Levels of Limiting ............................................................................................................36

6.8. Discharge High Pressure Trip Switch Function......................................................................36

6.9. Oil Management Systems ......................................................................................................37

6.9.1. Summary of Differential Pressure Sensing .....................................................................38

6.9.2. Demand Oil Pump...........................................................................................................40

6.9.3. Oil Filling Pump ...............................................................................................................41

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 6 of 270 Issue 3.3 : 01/23

7. Fridgewatch System Controller and SCADA .............................................................. 42

7.1. Fridgewatch System Controller ..............................................................................................42

7.2. SCADA System......................................................................................................................42

8. Installation ................................................................................................................... 45

8.1. Digital Inputs and Outputs......................................................................................................45

8.2. Analogue Inputs - Installing Transmitters...............................................................................45

8.2.1. Transmitter Wiring...........................................................................................................46

8.2.2. Transmitter Enabling and Calibration ..............................................................................46

8.3. Using Fridgewatch 4000 to Drive Relays ...............................................................................46

9. Status Indicators ......................................................................................................... 48

10. User Interface.............................................................................................................. 48

10.1. ‘Hard’ and ‘Soft’ Display Function Buttons .............................................................................48

10.2. Interface Common to Every Page ..........................................................................................48

10.2.1. Time and Date.................................................................................................................48

10.2.2. Access Level ...................................................................................................................48

10.2.3. Reset Required Indicator, Acknowledge and Reset Buttons ...........................................49

10.2.4. Current Alarms and Alarm History...................................................................................49

10.2.5. Menu Page......................................................................................................................49

10.2.6. Home Page and DIGINs .................................................................................................50

10.2.7. Back/Next, Analogue Inputs and P + I Diagnostics .........................................................50

11. Home Page ................................................................................................................. 51

11.1. Start (Manual Start/Stop Only) ...............................................................................................53

11.2. Load and Unload (Manual Capacity Control Only).................................................................53

11.3. Controlled Stop/Stop Button RESET......................................................................................53

11.4. System Diagnostics ...............................................................................................................54

12. Menu Page.................................................................................................................. 55

12.1. Read-only Pages ...................................................................................................................56

12.1.1. Digital Inputs ...................................................................................................................56

12.1.2. Digital Outputs.................................................................................................................58

12.1.3. Analogue Inputs ..............................................................................................................60

12.1.4. Analogue Outputs ...........................................................................................................62

12.1.5. P + I Diagnostics .............................................................................................................63

12.1.6. Primary/Secondary..........................................................................................................64

12.1.7. Trending and Logging Data.............................................................................................65

12.1.8. Clean Screen ..................................................................................................................76

12.2. Operator Settings Pages........................................................................................................77

12.2.1. System Control Settings..................................................................................................77

12.2.2. Economiser Control Settings...........................................................................................79

12.2.3. Liquid Injection Control Settings......................................................................................80

12.2.4. Evaporator and Oil Cooler Control Settings ....................................................................81

12.2.5. Condenser Control Settings ............................................................................................82

12.2.6. Hot Gas Valve Control Settings.......................................................................................83

12.2.7. Suction Pressure Limiting Control Settings .....................................................................84

12.2.8. Primary/Secondary Control Settings ...............................................................................85

12.2.9. Alarm, Limiting and Trip Settings, Delay Times...............................................................86

12.2.10. Operating Mode ..............................................................................................................92

12.2.11. Set Time and Date ..........................................................................................................93

12.3. Configuration Settings Pages ................................................................................................94

12.3.1. ANIN Configuration .........................................................................................................94

12.3.2. System Configuration Settings ........................................................................................97

12.3.3. Hours Run and Number of Starts ..................................................................................101

12.3.4. Simulate Outputs...........................................................................................................101

13. Passwords................................................................................................................. 102

13.1. Password Security ...............................................................................................................102

13.2. Entering a Password............................................................................................................103

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 7 of 270

14. Commissioning.......................................................................................................... 104

14.1. Supplying Power for the First Time ......................................................................................104

14.2. Commissioning – Sequence of Operations ..........................................................................104

14.2.1. Authority to Use Passwords ..........................................................................................105

14.3. Inputting System Configuration Settings ..............................................................................105

14.3.1. Changing System Configuration Settings after Commissioning ....................................106

14.4. Inputting Operator Settings ..................................................................................................106

14.4.1. Changing Operator Settings after Commissioning ........................................................106

14.5. Operating Mode for the First Start........................................................................................106

15. Display Messages..................................................................................................... 111

15.1. Information Only Messages .................................................................................................111

15.2. Alarm Messages ..................................................................................................................111

15.3. Trip Messages .....................................................................................................................111

15.4. Alarm, Trip and Information Only Messages........................................................................112

15.4.1. Suction Pressure: Alarm, Limiting and Trip ...................................................................112

15.4.2. Suction Temperature High: Trip ....................................................................................112

15.4.3. Suction Superheat: Alarm .............................................................................................112

15.4.4. Discharge Pressure High: Alarm, Limiting and Trip.......................................................113

15.4.5. Discharge Temperature High: Alarm and Trip...............................................................113

15.4.6. Discharge Superheat: Alarm .........................................................................................113

15.4.7. Oil Differential Pressure at Start-up (ODP2) Low: Trip..................................................114

15.4.8. Oil Differential Pressure During Running (ODP1) Low: Alarm and Trip ........................114

15.4.9. Oil Filter Differential Pressure High: Alarm and Trip......................................................115

15.4.10. Oil Injection Temperature High: Alarm and Trip ............................................................115

15.4.11. Lube Oil Temperature High: Alarm and Trip .................................................................115

15.4.12. Oil Separator/Reservoir Level Low: Trip .......................................................................116

15.4.13. Oil Drain Not Clear: Information and Trip ......................................................................116

15.4.14. Compressor Slide Valve Position (Motor Speed) Error: Alarm ......................................116

15.4.15. Compressor Failed to Unload: Trip ...............................................................................116

15.4.16. Condenser Cooling Medium Inlet Temperature: Alarm .................................................117

15.4.17. Condenser Cooling Medium Outlet Temperature: Alarm ..............................................117

15.4.18. Condenser Cooling Medium Differential Pressure Low: Alarm and Trip .......................117

15.4.19. Evaporator Cooled Medium Inlet Temperature: Alarm ..................................................117

15.4.20. Evaporator Cooled Medium Outlet Temperature: Alarm, Limiting and Trip ...................118

15.4.21. Evaporator Cooled Medium Differential Pressure: Alarm and Trip................................118

15.4.22. Evaporator Liquid Level: Alarm and Trip .......................................................................119

15.4.23. Compressor Motor Current: Limiting .............................................................................119

15.4.24. Compressor Motor Temperature High: Trip...................................................................119

15.4.25. Compressor Motor or Starter Failure.............................................................................120

15.4.26. Oil Pump Motor or Starter Failure .................................................................................121

15.4.27. Condenser Pump/Fan Motor or Starter Failure .............................................................122

15.4.28. Evaporator Cooled Medium Pump Motor or Starter Failure ..........................................123

15.4.29. User Trip .......................................................................................................................123

15.4.30. Emergency Stop Pressed .............................................................................................123

15.4.31. Starting or Loading Inhibited .........................................................................................124

15.4.32. Force Unload.................................................................................................................124

15.4.33. External Controller Fault: Evaporator, Economiser, Oil Rectifier or Liquid Injection......125

15.4.1. User Input Faults 1 and 2 (DIGINs I301.4 and I301.5) ..................................................125

15.4.1. Refrigerant Leak Detector .............................................................................................126

15.4.2. Transmitter Out of Range..............................................................................................126

16. External Reset and Alarms, Clearing Alarms and Trips ........................................... 127

16.1. External Alarm/Trip Acknowledge/Reset..............................................................................127

16.2. External Audible and Visual Alarms .....................................................................................127

16.3. Compressor Healthy Signal .................................................................................................127

16.4. Identifying and Clearing Alarms and Trips ...........................................................................127

16.4.1. Normal Healthy Condition .............................................................................................127

16.4.2. Alarm Condition.............................................................................................................128

16.4.3. Acknowledge Alarm ......................................................................................................128

16.4.4. Trip Event......................................................................................................................128

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 8 of 270 Issue 3.3 : 01/23

17. Operator Settings...................................................................................................... 132

17.1. System Control Settings ......................................................................................................132

17.1.1. Set Point, Start and Stop Values...................................................................................133

17.1.2. Stop-to-Start Time Differential.......................................................................................133

17.1.3. Proportional and Integral (P + I) Control........................................................................133

17.1.4. Compressor Unload Limit..............................................................................................134

17.1.5. Load and Unload Pulse Duration ..................................................................................134

17.1.6. Intermediate Load Outputs............................................................................................135

17.1.1. Variable Volume Ratio (VVR) Configuration

For HallScrew 5200 and 6200 Series Compressors .....................................................137

17.2. Economiser Control Settings ...............................................................................................138

17.2.1. Economiser Control Enable and Disable.......................................................................140

17.3. Liquid Injection Control Settings...........................................................................................141

17.4. Evaporator and Oil Cooler Control Settings .........................................................................143

17.4.1. Evaporator Control Settings ..........................................................................................143

17.4.2. Oil Cooler Control Settings............................................................................................145

17.5. Condenser Control Settings .................................................................................................146

17.6. Hot Gas Bypass Valve Control Settings...............................................................................148

17.7. Primary/Secondary Control Settings ....................................................................................150

17.8. Suction Pressure Limiting Control Valve Settings ................................................................151

17.9. Alarm, Limiting and Trip Settings, Delay Times ...................................................................153

17.9.1. Motor Current High........................................................................................................153

17.9.2. Discharge Pressure High ..............................................................................................153

17.9.3. Suction Pressure Low ...................................................................................................154

17.9.4. Suction Pressure High ..................................................................................................155

17.9.5. Oil Differential Pressure Low at Start-up .......................................................................155

17.9.6. Oil Differential Pressure Low During Running ...............................................................156

17.9.7. Oil Filter Differential Pressure High ...............................................................................157

17.9.8. Oil Injection Temperature High......................................................................................157

17.9.9. Lube Oil Temperature High ...........................................................................................158

17.9.10. Discharge Temperature High ........................................................................................158

17.9.11. Suction Temperature High ............................................................................................158

17.9.12. Condenser Cooling Medium Inlet Temperature High or Low.........................................158

17.9.13. Condenser Cooling Medium Outlet Temperature High or Low......................................158

17.9.14. Condenser Cooling Medium Differential Pressure Low.................................................159

17.9.1. Evaporator Cooled Medium Inlet Temperature High or Low .........................................159

17.9.2. Evaporator Liquid Level ................................................................................................160

17.9.3. Evaporator Cooled Medium Outlet Temperature Low ...................................................161

17.9.4. Evaporator Cooled Medium Outlet Temperature High ..................................................162

17.9.5. Evaporator Cooled Medium Differential Pressure High.................................................162

17.9.6. Evaporator Cooled Medium Differential Pressure Low..................................................163

17.9.7. Suction Superheat High ................................................................................................163

17.9.8. Suction Superheat Low .................................................................................................164

17.9.9. Discharge Superheat High ............................................................................................164

17.9.10. Discharge Superheat Low .............................................................................................165

17.9.11. Unload Pulses Per Sample Time ..................................................................................165

17.9.12. Oil Drain Delay Time .....................................................................................................165

17.9.13. User Trip Nuisance Trip Delay Time .............................................................................165

17.9.14. Oil Separator/Reservoir Nuisance Trip Delay Time.......................................................165

18. Configuration Settings............................................................................................... 166

18.1. ANIN Configuration, Calibration and Scaling .......................................................................166

18.1.1. Transmitter Calibration Overview ..................................................................................166

18.1.2. Pressure Transmitter Calibration...................................................................................167

18.1.3. Temperature Transmitter Calibration ............................................................................168

18.1.4. Motor Current Transmitter Calibration ...........................................................................169

18.1.5. Compressor Slide Valve Position LVDT Calibration ......................................................169

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 9 of 270

18.2. System Configuration...........................................................................................................170

18.2.1. Compressor Number.....................................................................................................170

18.2.2. System Refrigerant .......................................................................................................170

18.2.3. Compressor Drive .........................................................................................................171

18.2.4. Compressor Number of Starts.......................................................................................171

18.2.5. Oil Management System ...............................................................................................171

18.2.6. Oil Differential Pressure at Start-up...............................................................................171

18.2.7. Oil Differential Pressure During Running ......................................................................172

18.2.8. Oil Filter Differential Pressure .......................................................................................173

18.2.9. Compressor Capacity Control Valve Type ....................................................................174

18.2.10. Compressor Slide Valve Position/Motor Speed Correction ...........................................175

18.2.11. Slide Valve Position/Motor Speed Value For Minimum Load ........................................177

18.2.12. Compressor Fails to Unload at Start .............................................................................177

18.2.13. Control, Start and Stop Variables, Second Set Point ....................................................177

18.2.14. Run Enable Signal ........................................................................................................178

18.2.15. Compressor Start Time .................................................................................................179

18.2.16. Oil Pump Start Time and Minimum Run Time ...............................................................179

18.2.17. Demand Oil Pump Start and Stop .................................................................................179

18.2.18. Evaporator Pump Selection, Start and Run Times........................................................180

18.2.19. Condenser Start Time and Run-on Time ......................................................................180

18.2.20. Pump-down ...................................................................................................................180

18.2.21. Oil Rectifier Enable .......................................................................................................181

18.2.22. Economiser Superheat Control Enable .........................................................................181

18.2.23. Evaporator Superheat or Liquid Level Control Enable ..................................................182

18.2.24. Liquid Injection Control Enable......................................................................................182

18.2.25. Condensing Pressure Control Enable ...........................................................................182

18.2.26. Compressor Slide Valve Position/Motor Speed Definition.............................................183

18.2.27. Operating Mode Indication ............................................................................................183

18.2.28. Communications ...........................................................................................................183

18.2.29. Hot Gas Bypass Valve or Suction Pressure Limiting Control Enable ............................184

18.2.30. HallScrew Compressor Variable Volume Ration (VVR) Enable and Slide Valve Option184

18.2.31. Primary/Secondary........................................................................................................185

18.2.32. Variable Speed Drive ....................................................................................................185

18.2.33. Measurement Units .......................................................................................................185

19. Maintenance.............................................................................................................. 187

19.1. Maintenance Check List.......................................................................................................187

20. Spares....................................................................................................................... 187

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 10 of 270 Issue 3.3 : 01/23

List of Figures

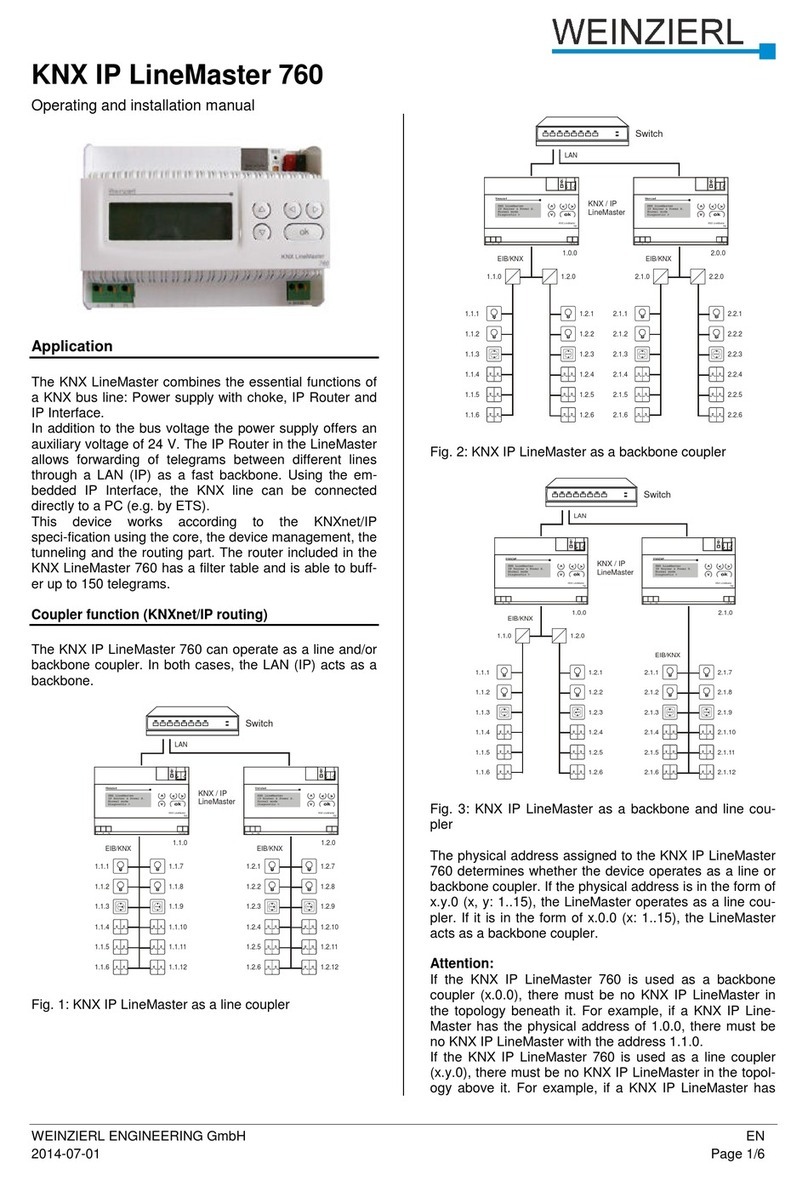

Fig 1 Fridgewatch 4000 Controller (Standalone Versions) – Front Panel and HMI Displays ................18

Fig 2 Fridgewatch 4000 Controller (Standalone Standard Version) – Panel Internal Layout................19

Fig 3 Fridgewatch 4000 Controller (Standalone Standard and Harsh Environment Versions) -

Enclosure .................................................................................................................................21

Fig 4 Fridgewatch 4000 Controller (Standalone Arrangement) - Mounting...........................................22

Fig 5 Proportional and Integral (P + I) Control ......................................................................................28

Fig 6 Integral Control Action .................................................................................................................30

Fig 7 Possible Compressor Start/Stop and Capacity Control Modes....................................................33

Fig 8 Fridgewatch 4000 Controller Interface With Fridgewatch System Controller...............................43

Fig 9 Fridgewatch 4000 Controller Interface With SCADA ...................................................................44

Fig 10 Digital Inputs With Inputs Connected (Page 1 Illustrated)..........................................................45

Fig 11 Connecting Diodes ....................................................................................................................46

Fig 12 Transmitter Installation ..............................................................................................................47

Fig 13 Home Page Example: Compressor in ‘Off’ Mode and SC1 and SC2 Not Configured ...............51

Fig 14 Home Page Example: Compressor ‘Available’ ..........................................................................52

Fig 15 Home Page Example: Compressor ‘Tripped’.............................................................................52

Fig 16 System Diagnostics Page..........................................................................................................54

Fig 17 Menu Page ................................................................................................................................55

Fig 18 Digital Inputs Pages 1 to 3.........................................................................................................56

Fig 19 Digital Outputs Pages 1 to 3 ......................................................................................................58

Fig 20 Analogue Inputs Pages 1 to 4....................................................................................................60

Fig 21 Analogue Outputs Pages 1 and 2..............................................................................................62

Fig 22 P + I Diagnostics Page ..............................................................................................................63

Fig 23 Primary Compressor Page ........................................................................................................64

Fig 24 Secondary Compressor Page....................................................................................................64

Fig 25 Trending and Logging Data Page..............................................................................................65

Fig 26 Trending Data – Evaporator Inlet and Outlet Temperature........................................................65

Fig 27 Trending Data – Condenser Inlet and Outlet Temperature........................................................66

Fig 28 Trending Data – Compressor Discharge, Suction and Oil Temperature....................................66

Fig 29 Trending Data – Compressor Discharge, Suction and Oil Injection Pressure............................67

Fig 30 Trending Data – Compressor Capacity......................................................................................67

Fig 31 Trending Data – Compressor Motor Current .............................................................................68

Fig 32 Trending Data – Compressor Lub Oil and Net Oil Pressure, Oil Filter Differential Pressure .....68

Fig 33 Trending Data – Compressor Discharge and Suction Superheat ..............................................69

Fig 34 Trending Example 1 ..................................................................................................................70

Fig 35 Trending Example 1 ..................................................................................................................70

Fig 36 Connecting to the CPU via Ethernet Cable................................................................................72

Fig 37 Trending and Logging Data – Data Logging ..............................................................................73

Fig 38 Uploading Data Log Files ..........................................................................................................74

Fig 39 Clean Screen.............................................................................................................................76

Fig 40 System Control Settings Pages 1 to 3 .......................................................................................77

Fig 41 Economiser Control Settings Pages 1 and 2 .............................................................................79

Fig 42 Liquid Injection Control Settings Page .......................................................................................80

Fig 43 Evaporator and Oil Cooler Control Settings Pages 1 and 2.......................................................81

Fig 44 Condenser Control Settings Page .............................................................................................82

Fig 45 Hot Gas Valve Control Settings Page........................................................................................83

Fig 46 Suction Pressure Limiting Control Settings Page ......................................................................84

Fig 47 Primary/Secondary Control Settings Page ................................................................................85

Fig 48 Alarm, Limit & Trip Settings Pages 1 to 11 ................................................................................86

Fig 49 Operating Mode Page................................................................................................................92

Fig 50 Set Time and Date Page ...........................................................................................................93

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 11 of 270

Fig 51 ANIN Configuration Pages 1 to 4...............................................................................................94

Fig 52 System Configuration Pages 1 to 6 ...........................................................................................97

Fig 53 Hours Run and Number of Starts Page ...................................................................................101

Fig 54 Screen Page Categories and Colour Coding...........................................................................102

Fig 55 Password Logon......................................................................................................................103

Fig 56 Viewing or Changing System Configuration Settings ..............................................................107

Fig 57 Viewing or Changing Control Settings .....................................................................................108

Fig 58 Viewing or Changing Operator Settings...................................................................................109

Fig 59 Identifying and Clearing Alarms and Trips ...............................................................................129

Fig 60 Limiting, Alarm and Alarm History Screens .............................................................................131

Fig 61 Example of Using Intermediate Load Output 1 ........................................................................136

Fig 62 Cycle Time...............................................................................................................................139

Fig 63 Discharge Pressure High: Settings ALT9, ALT10, ALT11, ALT12 and ALTT3 ........................154

Fig 64 Suction Pressure Low: Settings ALT2, ALT3, ALT7, ALT8 and ALTT2 ...................................155

Fig 65 Oil Differential Pressure Low During Running: Settings

ALT14, ALT15, ALTT5, ALTT6 and ALTT27 ..........................................................................157

Fig 66 Condenser Cooling Medium Differential Pressure Low: Settings

ALT43, ALT44, ALTT23, ALTT31 and ALTT33 ......................................................................160

Fig 67 Evaporator Liquid Level: Settings ALT51, ALT52, ALT53, ALTT34 and ALTT35 ....................161

Fig 68 Evaporator Cooled Medium Outlet Temperature Low: Settings

ALT24, ALT25, ALT26, ALT27 and ALTT11 ..........................................................................162

Fig 69 Evaporator Cooled Medium Differential Pressure Low: Settings

ALT33, ALT34, ALTT14, ALTT16 and ALTT32 ......................................................................164

Fig 70 Transmitter Calibration ............................................................................................................166

Fig 71 Transmitter Calibration - Examples .........................................................................................167

Fig 72 Slide Valve Position (SVP)/Motor Speed: Error Tolerance - Values For SC11........................176

Fig 73 Example of FW4000 Display Page in Metric and Imperial Units..............................................186

Fig 74 FW4000 Stand-alone Version Internal Equipment Layout and Terminal Arrangement ...........188

Fig 75 Panel Isolator IQ1 for Incoming 24 V dc 10 Amp Supply .........................................................191

Fig 76 Terminal Nomenclature and Identification ...............................................................................191

Fig 77 Slot 1 CPU on Board DIGINS, Addresses I100.0 to I101.5, ANIN 24 and ANOUT 6 ..............192

Fig 78 Slot 2 CPU on Board DIGINS, Addresses I200.0 to I201.7 .....................................................194

Fig 79 Slot 3 CPU on Board DIGINS, Addresses I300.0 to I301.7 .....................................................196

Fig 80 Slot 1 CPU on Board DIGOUTS, Addresses Q100.0 to Q101.1..............................................198

Fig 81 Slot 2 CPU on Board DIGOUTS, Addresses Q200.0 to Q201.7..............................................200

Fig 82 Slot 3 CPU on Board DIGOUTS, Addresses Q300.0 to Q301.7..............................................202

Fig 83 Slot 4 ANINS 0 to 3, ANOUTS 0 and 1....................................................................................204

Fig 84 Slot 5 ANINS 4 to 7, ANOUTS 2 and 3....................................................................................205

Fig 85 Slot 6 ANINS 8 to 11, ANOUTS 4 and 5..................................................................................206

Fig 86 Slot 7 ANINS 12 to 15..............................................................................................................207

Fig 87 Slot 8 ANINS 16 to 19..............................................................................................................208

Fig 88 Slot 9 ANINS 20 to 23..............................................................................................................209

Fig 89 RS 485 Communication Board ................................................................................................210

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 12 of 270 Issue 3.3 : 01/23

List of Tables

Table 1 Abbreviations...........................................................................................................................16

Table 2 Fridgewatch 4000 Controller (Standalone Versions) – Technical Data ...................................17

Table 3 Analogues, Settings and Delay Times.....................................................................................23

Table 4 Options For Set Point Control..................................................................................................24

Table 5 Set Point, Start and Stop Values, Second Set Point Value and Set Point Override ................25

Table 6 Summary of Limiting Inputs and Associated Settings..............................................................35

Table 7 Summary of Differential Pressure Sensing ..............................................................................37

Table 8 All HallScrew Compressors – Oil Pressure Trips by Differential Pressure Switches ...............38

Table 9 HSO 2000 Series Compressors - Oil Pressure Trips by Transmitters .....................................39

Table 10 HS 3100, HS 3200, HS 4200, HS 5200 and HS 6200 Series Compressors -

Oil Pressure Trips by Transmitters...........................................................................................40

Table 11 ‘Hard’ and ‘Soft’ Display Function Buttons.............................................................................48

Table 12 Suction Pressure: Alarm, Limiting and Trip..........................................................................112

Table 13 Suction Temperature High: Trip...........................................................................................112

Table 14 Suction Superheat: Alarm....................................................................................................112

Table 15 Discharge Pressure High: Alarm, Limiting and Trip .............................................................113

Table 16 Discharge Temperature High: Alarm and Trip .....................................................................113

Table 17 Discharge Superheat: Alarm................................................................................................113

Table 18 Oil Differential Pressure at Start-up (ODP2) Low: Trip ........................................................114

Table 19 Oil Differential Pressure During Running (ODP1) Low: Alarm and Trip ...............................114

Table 20 Oil Filter Differential Pressure High: Alarm and Trip ............................................................115

Table 21 Oil Injection Temperature High: Alarm and Trip...................................................................115

Table 22 Lube Oil Temperature High: Alarm and Trip ........................................................................115

Table 23 Oil Separator/Reservoir Level Low: Trip ..............................................................................116

Table 24 Oil Drain Not Clear: Information and Trip.............................................................................116

Table 25 Compressor Slide Valve Position (Motor Speed) Error: Alarm ............................................116

Table 26 Compressor Failed to Unload: Trip ......................................................................................116

Table 27 Condenser Cooling Medium Inlet Temperature: Alarm........................................................117

Table 28 Condenser Cooling Medium Outlet Temperature: Alarm .....................................................117

Table 29 Condenser Cooling Medium Differential Pressure Low: Alarm and Trip ..............................117

Table 30 Evaporator Cooled Medium Inlet Temperature: Alarm.........................................................117

Table 31 Evaporator Cooled Medium Outlet Temperature: Alarm, Limiting and Trip .........................118

Table 32 Evaporator Cooled Medium Differential Pressure: Alarm and Trip ......................................118

Table 33 Evaporator Liquid Level: Alarm and Trip..............................................................................119

Table 34 Compressor Motor Current: Limiting....................................................................................119

Table 35 Compressor Motor Temperature High: Trip .........................................................................119

Table 36 Compressor Motor or Starter Failure ...................................................................................120

Table 37 Oil Pump Motor or Starter Failure ........................................................................................121

Table 38 Condenser Pump/Fan Motor or Starter Failure....................................................................122

Table 39 Evaporator Cooled Medium Pump Motor or Starter Failure.................................................123

Table 40 User Trip..............................................................................................................................123

Table 41 Emergency Stop Pressed ....................................................................................................123

Table 42 Starting or Loading Inhibited................................................................................................124

Table 43 Force Unload .......................................................................................................................124

Table 44 External Controller Fault: Evaporator, Economiser, Oil Rectifier or Liquid Injection ............125

Table 45 User Input Faults 1 and 2 ....................................................................................................125

Table 46 Refrigerant Leak Detector....................................................................................................126

Table 47 External Alarms DIGOUTs Q201.5 and Q201.6 Behaviour .................................................127

Table 48 Variable Volume Ratio (VVR) Applications, Values For S20 and SC48 ...............................137

Table 49 System Refrigerant Type - Values For SC2.........................................................................170

Table 50 Oil Differential Pressure (ODP2) Sensing Defined - Values For SC7 ..................................172

Table 51 Oil Differential Pressure (Running) ODP1 Sensing Defined - Values For SC8....................172

Table 52 Oil Filter Differential Sensing Defined - Values For SC9......................................................173

Table 53 Capacity Control Valve Application and Operation - Values For SC10................................174

Table 54 Run Enable Required in Different Operating Modes - Values for SC18...............................178

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 13 of 270

Table 55 Operating Mode Indication - Values For SC42 ....................................................................183

Table 56 Metric Pressure Transmitter and Temperature Sensor Ranges Used With FW4000 ..........186

Table 57 Maintenance Check List ......................................................................................................187

Table 58 Fuses and Relays, Electronic Modules and HMI .................................................................189

Table 59 Residual Risk Register ........................................................................................................190

Table 60 RS 485 Termination and Bias..............................................................................................210

Table 61 Analogue Input ANIN 00/ANIN 25 Quick-Reference and Calculated Values .......................212

Table 62 Analogue Inputs ANIN 00/ANIN 25 Transmitters .................................................................213

Table 63 Analogue Outputs ANOUT 00/ANOUT 07 ...........................................................................213

Table 64 Digital Inputs I100.0/I301.7 ..................................................................................................214

Table 65 Digital Outputs Q100.0/Q301.7............................................................................................216

Table 66 HMI Trip Display Messages.................................................................................................217

Table 67 HMI Alarm Display Messages..............................................................................................218

Table 68 HMI Limiting Display Messages...........................................................................................219

Table 69 HMI Out of Range Display Messages..................................................................................219

Table 70 HMI Out of Range Display Messages..................................................................................220

Table 71 SCADA Information: ANINS, Calculated Values, ANOUTS Etc...........................................221

Table 72 SCADA Information: ANIN Out of Range Flags...................................................................223

Table 73 SCADA Information: ALT Trip Flags ....................................................................................225

Table 74 SCADA Information: ALT Alarm Flags.................................................................................226

Table 75 SCADA Information: Limiting Flags .....................................................................................227

Table 76 SCADA Information: Alarm Inhibit Flags..............................................................................228

Table 77 SCADA Information: DIGINS ...............................................................................................229

Table 78 SCADA Information: DIGOUTS ...........................................................................................230

Table 79 SCADA Information: Communications.................................................................................231

Table 80 SCADA Information: Data Received....................................................................................231

Table 81 SCADA Information: Data Block 33 @ 4 mA and Data Block 34 @ 20 mA .........................232

Table 82 SCADA Information: Array ‘Elapsed Time Array For HMI Data Block 53’............................233

Table 83 SCADA Information: Array ‘Control Diagnostic Data’...........................................................234

Table 84 System Control Setting Addresses S1/S23 .........................................................................235

Table 85 Economiser Control Setting Addresses EC1/EC14 .............................................................236

Table 86 Evaporator Control Setting Addresses E1/E12 ....................................................................236

Table 87 Condenser Control Setting Addresses C1/C10 ...................................................................237

Table 88 Liquid Injection Control Setting Addresses LI1/LI9 ..............................................................237

Table 89 Hot Gas Bypass Valve Control Setting Addresses HG1/HG8..............................................237

Table 90 Primary/Secondary Control Setting Addresses PS1/PS5 ....................................................238

Table 91 Oil Cooler Control Setting Addresses OC1/OC2 .................................................................238

Table 92 Suction Pressure Limiting Control Valve Setting Addresses SPL1/SPL8 ............................238

Table 93 Alarm, Limiting and Trip Setting Addresses ALT0/ALT53....................................................239

Table 94 Alarm, Limiting and Trip Delay Time Setting Addresses ALTT0/ALTT35 ............................241

Table 95 Analogue Input Configuration Setting Addresses ANIN 00/ANIN 25 ...................................242

Table 96 System Configuration Setting Addresses SC1/SC53 ..........................................................244

Table 97 Compressor Number/Compressor Serial Number Record...................................................246

Appendices

Appendix 1 Residual Risk Register ....................................................................................................190

Appendix 2 Wiring Connections..........................................................................................................191

Appendix 3 Analogue Inputs and Outputs ..........................................................................................212

Appendix 4 Digital Inputs and Outputs ...............................................................................................214

Appendix 5 HMI Display Messages ....................................................................................................217

Appendix 6 SCADA Information .........................................................................................................221

Appendix 7 Control Setting Addresses ...............................................................................................235

Appendix 8 Settings Record ...............................................................................................................246

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 14 of 270 Issue 3.3 : 01/23

1. About this Publication

These instructions have been prepared according to the following

standards:

•BS EN ISO 11442: Technical product documentation.

Document management;

•BS EN ISO 12100: Safety of machinery - General principles

for design - Risk assessment and risk reduction;

•BS EN 62023: Structuring of technical information and

documentation;

•BS EN 82079-1: Preparation of instructions for use.

Structuring, content and presentation. General principles

and detailed requirements.

1.1. Safety Warnings and Symbols

The system of safety warnings and symbols is based on:

•BS EN ISO 7010: Graphical symbols. Safety colours and

safety signs. Registered safety signs;

•BS EN 82079-1: Preparation of instructions for use.

Structuring, content and presentation. General principles

and detailed requirements.

DANGER

This indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury if

instructions, including recommended precautions, are

not followed.

WARNING

This indicates a hazard with a medium level of risk,

which if not avoided, will result in death or serious

injury if instructions, including recommended

precautions, are not followed. In addition, there is a

high risk of damage to the component, product or

process.

CAUTION

This indicates a hazard with a low level of risk, which if

not avoided, will result in minor or moderate injury if

instructions, including recommended precautions, are

not followed. In addition, there is a potential risk of

damage to the component, product or process.

NOTE: Draws attention to important additional

information.

1.2. Units of Measurement

Quantities are expressed in SI units or SI derived units; refer to J & E Hall

International Standard JEH-ES-02 Guide to the International System of

Units (SI).

1.3. Terminology

Terminology, abbreviations and acronyms are those currently in use

throughout the refrigeration and air conditioning industry; refer to J & E

Hall International Standard JEH-ES-01 Definition of Terms and Acronyms

Used in the Refrigeration Industry.

1.4. Additional Copies

Obtain additional copies of these instructions from J & E Hall

International; go to www.jehall.com.

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 15 of 270

2. Care and Protection of Fridgewatch

CAUTION

If welding is to be carried out in the vicinity of the

Fridgewatch or any other items of plant containing

semi-conductor devices, for example, transistors and

microprocessors, the welding equipment must be

adequately earthed adjacent to the point of weld.

The Fridgewatch or other electronic devices must not be

positioned between the site where the welding is taking

place and the point of earth, or irrevocable damage may

be caused to the electronics, with possible

consequential damage to the plant.

2.1. Anti-Static Precautions

Electrostatic discharge can damage the memory card or the receptacle

on the CPU fitted to Fridgewatch.

Damage to the card or its components can occur as the result of

electrostatic discharge from or through personnel.

To protect the modules and components, precautions against

electrostatic hazards must be taken according to BS EN 61340-5-1.

Note the following:

•Persons handling electronic cards must be earthed, in

accordance with BS EN 61340-5-1, to the earth terminal on

the Fridgewatch or other suitable earthing point;

CAUTION

The earth bonding device, for example, wrist strap and

its application, must conform to BS EN 61340-5-1.

•Never remove or replace a component with the Fridgewatch

power supply turned on.

2.2. Electrical Interference

To avoid problems of electrical interference, all low voltage wiring

(transmitters, data communications and 24 V dc) must be adequately

separated from higher voltage ac wiring (110 V, 230 V, 400 V or higher).

A separation of 150 mm is desirable but not always achievable within

control panels.

Low voltage and higher voltage cables should cross at right-angles.

2.3. Prolonged Storage

If the Fridgewatch, or the plant of which it forms a part, is not to be

installed immediately but held in store, observe the following points:

•The Fridgewatch should preferably be stored indoors, in a

well ventilated, clean, warm and dry environment. If

equipment is stored outside, protection from the elements

must be provided; coverings should be selected and

arranged to reduce the risk of condensation;

•Fridgewatch should not be exposed to ambient temperatures

below -15.0 °C.

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 16 of 270 Issue 3.3 : 01/23

3. Abbreviations

The following abbreviations are used in this manual:

Abbreviation Description Abbreviation Description

∆P Delta P (Differential Pressure) LVDT Linear Variable Displacement Transducer

> Greater Than MOP Maximum Operating Pressure

< Less Than MV Measured Variable

≥Greater Than or Equal to NEMA National Electrical Manufacturers Association (USA)

≤Less Than or Equal to OC Oil Cooler

ALT Alarm, Limiting and Trip ODP Oil Differential Pressure

ALTT Alarm, Limiting and Trip delay Times P + I Proportional + Integral

ANIN ANalogue INput PA Proportional Action

ANOUT ANalogue OUTput PB Proportional Band

COP Coefficient Of Performance PLC Programmable Logic Controller

CPU Central Processing Unit PS Primary/Secondary

DCS Distributed Control System PT Pressure Transmitter, signal in millamps (mA) e.g. 4 to 20 mA

DIGIN DIGital INput RS Recommended Standard serial coms protocol (e.g. RS485)

DIGOUT DIGital OUTput RTU Remote Terminal Unit (e.g. Modbus RTU)

EC Economiser Control SCADA Supervisory Control and Data Acquisition

FW4000 FridgeWatch 4000 Controller SH SuperHeat

FW4100 FridgeWatch 4100 Controller SI International System of Units (SI)

FWDC FridgeWatch Duplex Controller SIS Safety Instrumentation System

FWSC FridgeWatch System Controller SP Set Point

FWSHC FridgeWatch SuperHeat Controller SPL Suction Pressure Limiting

GUI Graphical User Interface ST Sample Time

HG Hot Gas SVP Slide Valve Position

HMI Human-Machine Interface TR Trip

HP High Pressure TT Temperature Transmitter, signal in millamps (mA) e.g. 4 to 20 mA

Int Integer (number which is not a fraction; a whole number) VMS Vibration Monitoring System

IA Integral Action

IAT Integral Action Time

IP Ingress Protection

LI Liquid Injection

LP Low Pressure

Table 1 Abbreviations

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 17 of 270

4. General Description

The Fridgewatch 4000 Controller (FW4000) is a compact, Siemens S7

series PLC based, integrated solution for the control and management of

compressor packages and chillers fitted with a screw compressor, fixed

or variable speed drive. Fridgewatch replaces the collection of pressure,

temperature and motor current controllers, timers and relays that might

otherwise be used. In addition to the basic functions of compressor

starting and stopping, safety monitoring and capacity control, FW4000

adds a number of enhancements that permit compressor operation to be

optimised to suit the running conditions. Auxiliary control of compressor

liquid injection cooling or oil cooling, economiser and evaporator

expansion valves and condenser fans (fixed or variable speed drive)

means that separate controllers for these devices can be dispensed with,

resulting in a significant cost saving.

FW4000 electronics can be arranged in two ways. In each case the

functionality, number of analogue and digital inputs and outputs etc.

remains the same:

•Standalone versions: refer to 4.1;

•Integrated version: refer to 4.2.

4.1. Standalone Versions

There are two standalone versions: standard and for harsh environments

(for example, outdoors or marine).

The FW4000 standalone arrangement is illustrated in Figs 1 to 4; refer to

Table 2 for technical data.

Standard and

Harsh

Environments

Versions

Enlosure

Internal layout Refer to Fig 2

Specification, dimensions and cable entry Refer to Fig 3

Mounting Refer to Fig 4

Incoming wiring Use 0.5 mm2cable. Bottom entry only to enclosure.

Relays for

digital outputs

Number off Solid-state: 5 off, mechanical: 14 off single pole

Output 24 V dc

Contact rating 8 A continuous at 250 V ac, 3 A inductive at 250 V ac

Human-machine Interface (HMI) display Refer to Fig 1

Communications interface RS 485 – Modbus RTU or Profinet

DIGIN running signals for compressor, oil pump (if fitted) and auxiliaries 4 mA, 30 V dc maximum

Power supply 24 V dc ±10 % 10 Amp

Real-time clock Super capacitor, maintenance-free

Settings back-up Non-volatile memory

Status indicators On front panel for ‘Control On’ and ‘PLC Healthy’

Temperature

limits

Standard

version

Operating ambient temperature range 0.0 to 40.0 °C

Maximum temperature inside panel 50.0 °C

Harsh

environments

version

Operating ambient temperature range -15.0 to +40.0 °C

Maximum temperature inside panel 50.0 °C

Storage (all versions) -15.0 to +60.0 °C

Harsh

Environments

Version Only

Anti-condensation heater 20 W

Heater thermostat Range 0.0 to 60.0 °C. Set to energises heater if <5.0 °C.

Rain canopy (if required) Refer to Fig 3

Table 2 Fridgewatch 4000 Controller (Standalone Versions) – Technical Data

Fridgewatch 4000 Controller Mk2

Publication 3-71 Section 3

Page 18 of 270 Issue 3.3 : 01/23

4.1.1. Human-machine Interfaces (HMI) Displays

The FW4000 controller incorporates one of two different HMI displays,

usage depends on the environment in which the panel is located: indoors

or in a harsh environment; refer to Fig 1.

The KTP900 HMI display is featured in this manual.

KTP900 HMI Basic PN 2nd Generation TP700 HMI Comfort Outdoor

Standalone version usage Standard Harsh environments

Screen size (diagonal) 228.6 mm (9 in) 177.8 mm (7 in)

Display size Width 198 mm x height 111.7 mm Width 152.4 mm x height 91.4 mm

Touch-screen Yes Yes

IP rating IP65 (NEMA type 4 at the front) IP66 (NEMA type 4 at the front)

Fig 1 Fridgewatch 4000 Controller (Standalone Versions) – Front Panel and HMI Displays

HMI Display (KTP900 Illustrated)

‘PLC HEALTHY’

‘CONTROL ON’

Fridgewatch 4000 Controller Mk2

Section 3 Publication 3-71

Issue 3.3 : 01/23 Page 19 of 270

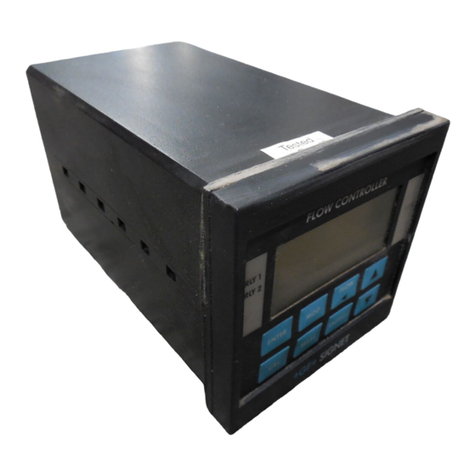

Fig 2 Fridgewatch 4000 Controller (Standalone Standard Version) – Panel Internal Layout

CPU

Earth Connecting Block

MCB

Trunking For Incoming Cables

Gland Plate For 24 V dc Cable Entry

Digital I/O Modules

Analogue I/O Modules

Analogue Input Modules

Ethernet

Module

Fuses

F1 to F5

Incoming

Isolator IQ1

SSR