Chapter 1

Introduction

1.1 Introduction

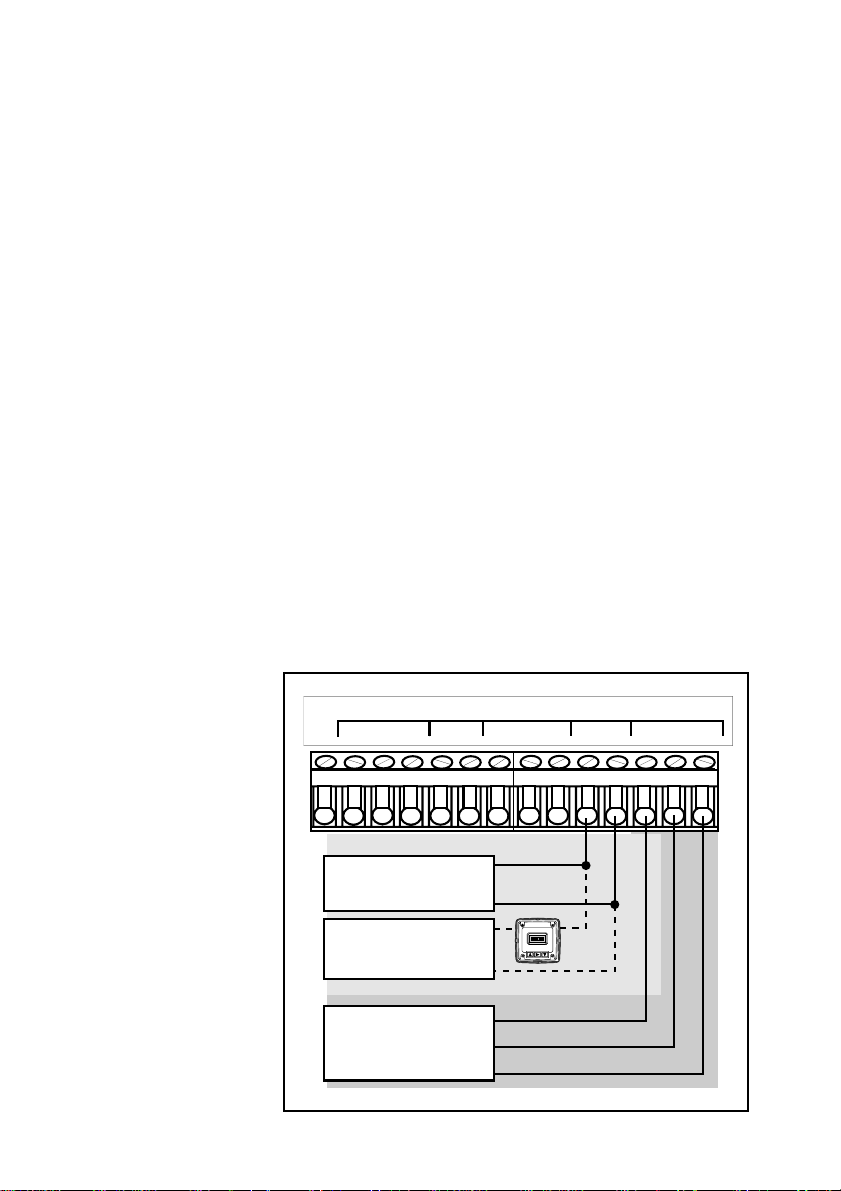

Your new +GF+SIGNET 9010 Intelek-Pro Flow

Controller has been specifically designed for liquid

flow rate measurement in process pipes. The

controller's compact 1/4 DIN enclosure (front) is

NEMA 4X/IP65 rated and ideal for installing into

instrumentation panels with limited space.

Modular "plug-in" input/output option cards allow

you to customize your flow controller to your flow

system's requirements. The controller's unique

"slide-out" chassis design makes option installation

fast and simple. Smart self-configuring

microprocessor based circuitry automatically

inventories installed options during power-up,

allowing you to upgrade your system in seconds

without the need for additional equipment.

The unit's front panel features a highly visible

4.5- digit (seven segment) and 8-digit (alpha-

numeric) liquid crystal display with adjustable

contrast. Active flow rate, accumulation, and

alarm relay information is quickly accessed at a

glance. During calibration the user is prompted

with clear step-by-step instructions on the unit's front

panel display.

The +GF+SIGNET 9010 Intelek-Pro Flow

Controller is fully compatible with all +GF+Signet

flow sensor products, yet also accepts other

analog inputs, such as 4 to 20 mA or

0 to 5 VDC etc.

The technical data given in

this publication is for general

information purposes only. It

implies no warranty of

whatever kind.

1