10

Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

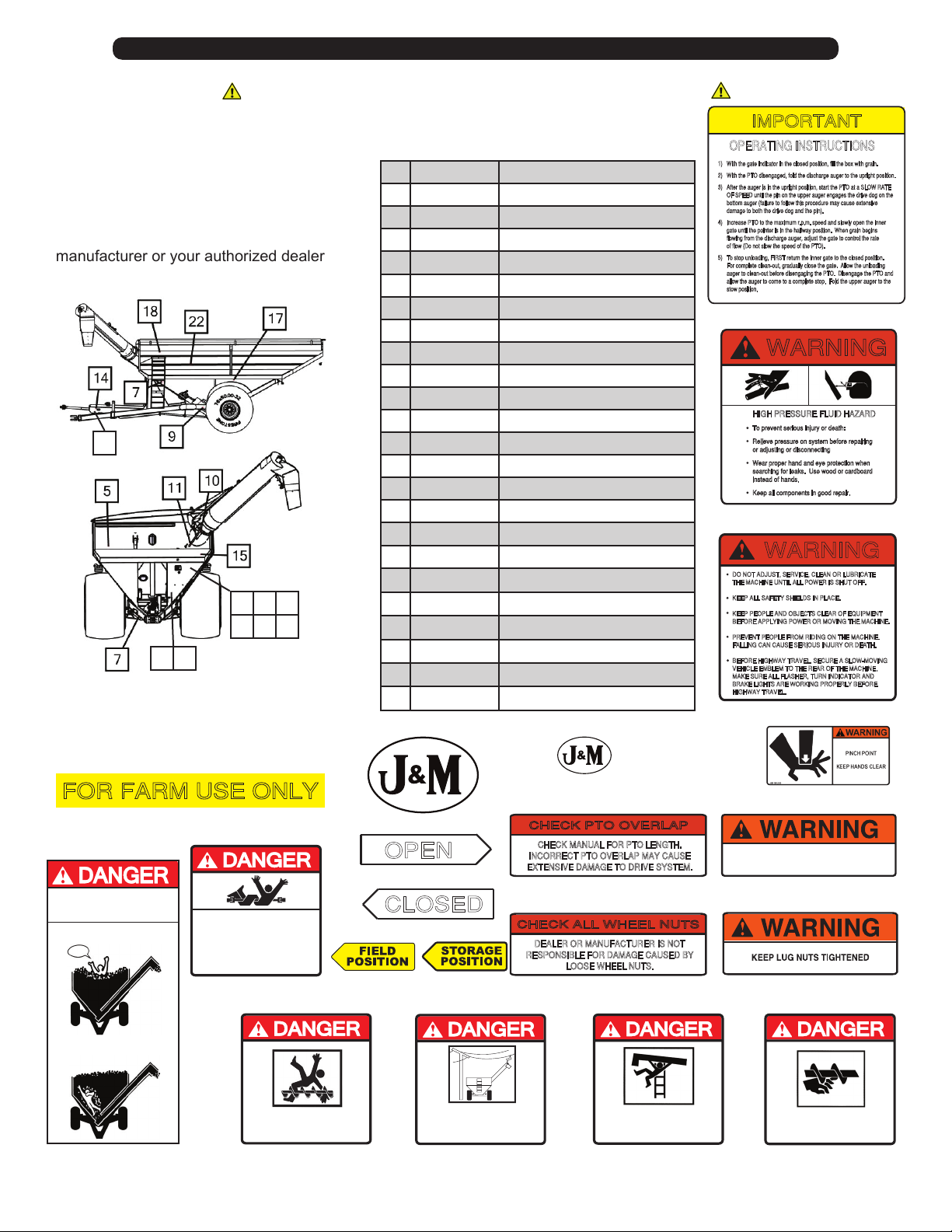

Replace Immediately If Damaged or Missing

IMPORTANT: Install new safety signs if

the old signs are destroyed, lost, painted

over or cannot be read. When parts are

replaced that have safety signs, make

sure you install a new sign with each new

part. New signs are available from the

manufacturer or your authorized dealer.

SAFETY DECALS

#1

#2

#3

#16

#17

#4

#8

#9

#21#20#19#18

DO NOT ENTER GRAIN TANK WHEN

AUGER IS RUNNING.

#14

#15

#11

#10

#5

#6

SERIOUS INJURY OR DEATH CAN RESULT

FROM CONTACT WITH ELECTRIC LINES.

USE CARE WHEN MOVING OR OPERATING

THIS MACHINE NEAR ELECTRIC LINES

TO AVOID CONTACT.

KEEP HANDS, FEET, HAIR AND

CLOTHING AWAY FROM MOVING PARTS

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH.

KEEP AWAY!

• Keep all guards in place when operating.

• Do NOT stand on steps or climb ladder until

all power is shut off.

• Keep hands, feet, hair and clothing away

from moving parts.

#Part # Description

1 JM0018044 Operating Instructions

2 JM0010163 Warning, High Pressure

3 JM0014979 Warning, General

4 JM0018038 Farm Use Only

5 JM0015151 J&M Oval Decal, Large

6 JM0010179 J&M Oval Decal, Medium

7 JM0014994 Warning, Pinch Point

8 JM0018037 Danger, Suocation

9 JM0018036 Danger, Rotating Driveline

10 JM0025433 Open

11 JM0025434 Closed

12 JM0027472 Field Position

13 JM0027473 Storage Position

14 JM0025435 Check PTO Overlap

15 JM0018043 Warning, Check Lug Nuts

16 JM0018039 Warning, Keep Hands Away

17 JM0010150 Warning, Lug Nuts

18 JM0018033 Danger, Do Not Enter Tank

19 JM0015099 Danger, Electric Lines

20 JM0018034 Danger, Keep O Ladder

21 JM0018035 Danger, Keep Hands Away

22 Specify AS Stripe Kit

23 Specify OAS Stripe Kit

#7

#12 #13

19

8 4 2

1 3

12 13

9